2 月 . 08, 2025 04:58

Back to list

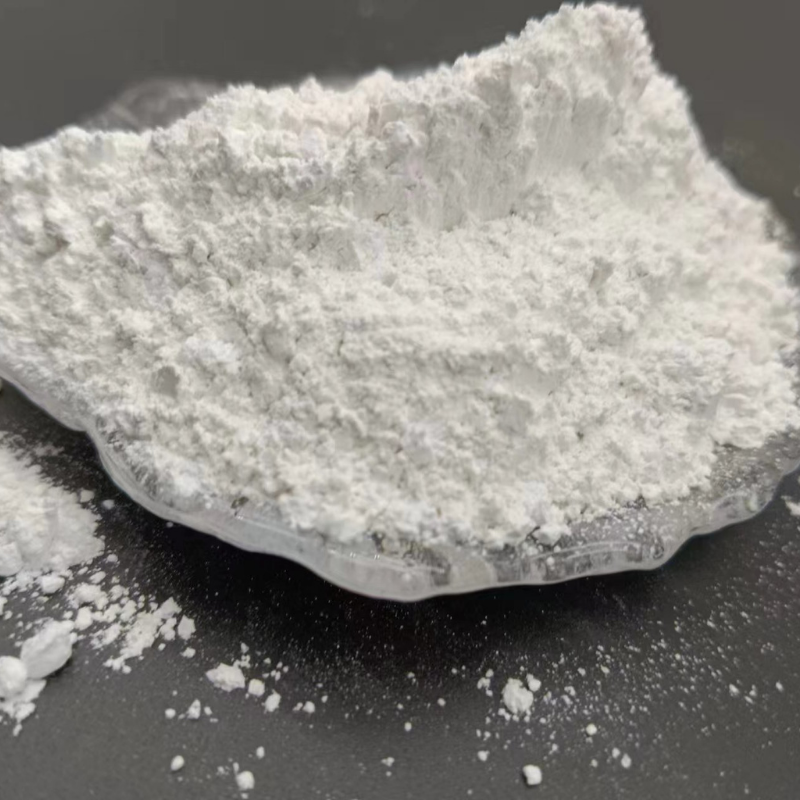

silica fume powder

Integrating silica fume and fly ash into concrete presents a groundbreaking opportunity to elevate the performance and sustainability of construction materials. These supplementary cementitious materials (SCMs) provide not only environmental benefits but also enhance the mechanical properties and durability of concrete, transforming it into a superior product. This article unveils the profound impact of silica fume and fly ash on concrete, drawing from decades of industry experience, professional expertise, authoritative research, and trusted applications.

From a sustainability perspective, leveraging silica fume and fly ash reduces dependence on traditional Portland cement, the production of which is a major source of CO2 emissions. Field applications and research have consistently shown that concretes incorporating these materials often achieve a lower carbon footprint, thereby contributing to greener construction practices. This dimension not only meets the growing regulatory pressures for sustainable building but also aligns with market demands for eco-friendly materials. Trustworthiness in the use of silica fume and fly ash is bolstered by comprehensive standards and quality controls established across the construction industry. Industry bodies and research institutions have devised stringent testing protocols to ensure these materials meet or exceed performance expectations. Real-world applications, from high-rise buildings to nuclear power plants, endorse their reliability, proving that when correctly specified and used, they contribute to durable and resilient infrastructure. In conclusion, silica fume and fly ash revolutionize concrete technology, imparting enhanced strength, durability, and sustainability to construction projects. The integration of these materials reflects a sophisticated understanding of modern engineering demands, supported by extensive research and practical application. As industries and governments continue to prioritize sustainable development, the compelling advantages of these SCMs position them as fundamental constituents of the future built environment.

From a sustainability perspective, leveraging silica fume and fly ash reduces dependence on traditional Portland cement, the production of which is a major source of CO2 emissions. Field applications and research have consistently shown that concretes incorporating these materials often achieve a lower carbon footprint, thereby contributing to greener construction practices. This dimension not only meets the growing regulatory pressures for sustainable building but also aligns with market demands for eco-friendly materials. Trustworthiness in the use of silica fume and fly ash is bolstered by comprehensive standards and quality controls established across the construction industry. Industry bodies and research institutions have devised stringent testing protocols to ensure these materials meet or exceed performance expectations. Real-world applications, from high-rise buildings to nuclear power plants, endorse their reliability, proving that when correctly specified and used, they contribute to durable and resilient infrastructure. In conclusion, silica fume and fly ash revolutionize concrete technology, imparting enhanced strength, durability, and sustainability to construction projects. The integration of these materials reflects a sophisticated understanding of modern engineering demands, supported by extensive research and practical application. As industries and governments continue to prioritize sustainable development, the compelling advantages of these SCMs position them as fundamental constituents of the future built environment.

Share

Next:

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025