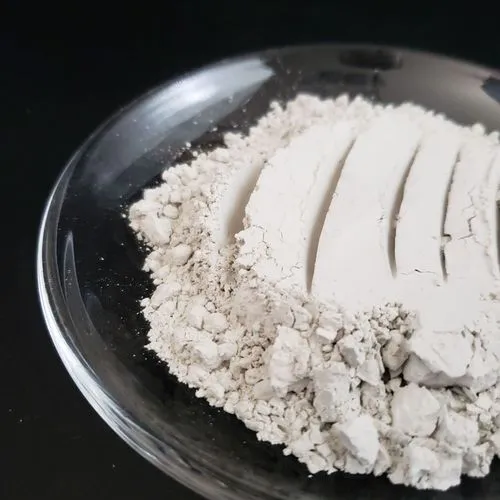

Mineral powder Is the product of grinding ore processing,

Mineral powder is a high fineness and high activity powder obtained after water quenching blast furnace slag, drying, grinding and other processes. It is a high-quality concrete admixture and cement mixture, and is recognized as an important material for preparing high-performance concrete in the world today. By using granulated blast furnace slag powder, the compressive strength of concrete can be effectively improved and the cost of concrete can be reduced. At the same time, it has obvious effect on inhibiting the reaction of alkali aggregate, reducing the heat of hydration, reducing the early temperature crack of concrete structure, improving the concrete compactness, and improving the anti-seepage and anti-erosion ability.

Significant efficiency of granulated blast furnace slag powder:

1. Save the amount of cement by 30-60% (including cement mortar), reduce the cost of cement and concrete engineering.

2. It has the effect of volcanic ash, which increases the compressive, tensile, bending and shear strength of concrete.

3. Significantly reduce the hydration heat of concrete, improve the workability of concrete, reduce segregation and bleeding, reduce the temperature difference and internal stress of large volume concrete, and inhibit cracks caused by temperature difference.

4. It can inhibit alkali aggregate reaction and significantly improve the ability of concrete to resist alkali aggregate reaction.

5, can exist in the form of micro-aggregate in concrete, improve the pore structure in concrete, so that the aperture can be refined and homogenized, improve the permeability of concrete, freeze-thaw resistance and durability.

6. It can significantly reduce the water yield of cement concrete and improve the workability of cement concrete.

7, it can effectively improve the corrosion resistance of cement concrete to seawater and fresh water, and resist the corrosion of sulfate. It is especially suitable for anti-seawater engineering, underground engineering and pavement engineering.

8, in the case of constant water consumption, plastic concrete can be prepared to avoid quality problems due to dense reinforcement and poor vibration. Under the same condition, it can make the concrete flow into the mold, reduce the wear of the concrete pump body, pipeline and mold, and extend its service life.

9, can be prepared masonry, plastering cement mortar and low grade cement. In the case of meeting the strength requirements, not only can save 30-60% of the cement, but also improve the construction operability.

10. Suitable for the production of environmentally compatible cement-based materials and high performance concrete admixtures.

Share

-

Chlorolite is obtained from zeolite ore by high temperature sintering and dehydration treatment.NewsMay.24,2024

-

The main component of talc is magnesium silicate containing talc water,NewsMay.22,2024

-

Alumina is a high-hardness compound commonly used in the manufacture of refractory materials.NewsMay.20,2024

-

Hollow glass beads are tiny, hollow glass spheres,NewsMay.16,2024

-

Fused quartz is the amorphous (glassy) state of silicon oxide (quartz, silica).NewsMay.09,2024

-

Vermiculite is a natural, inorganic, non-toxic mineral that expands under high temperature.NewsApr.09,2024