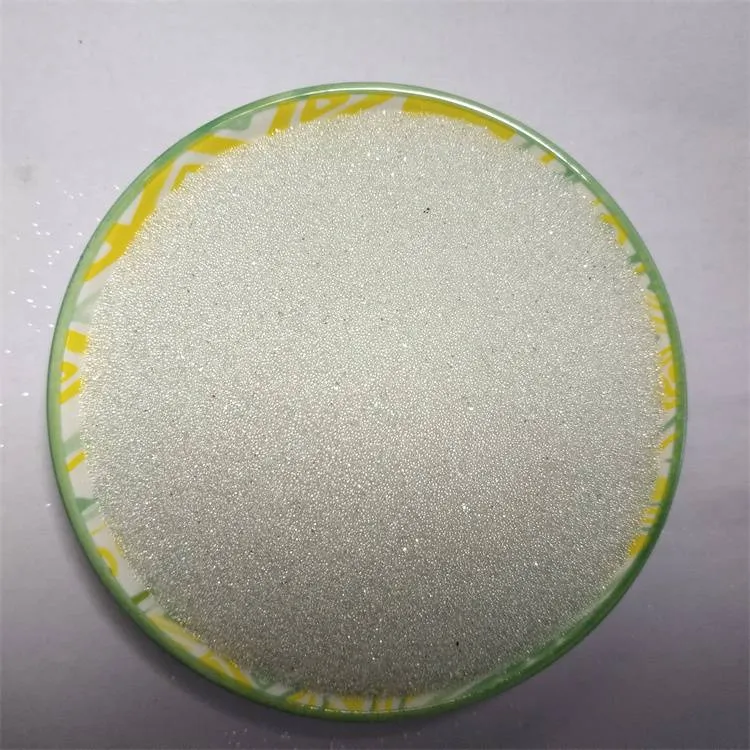

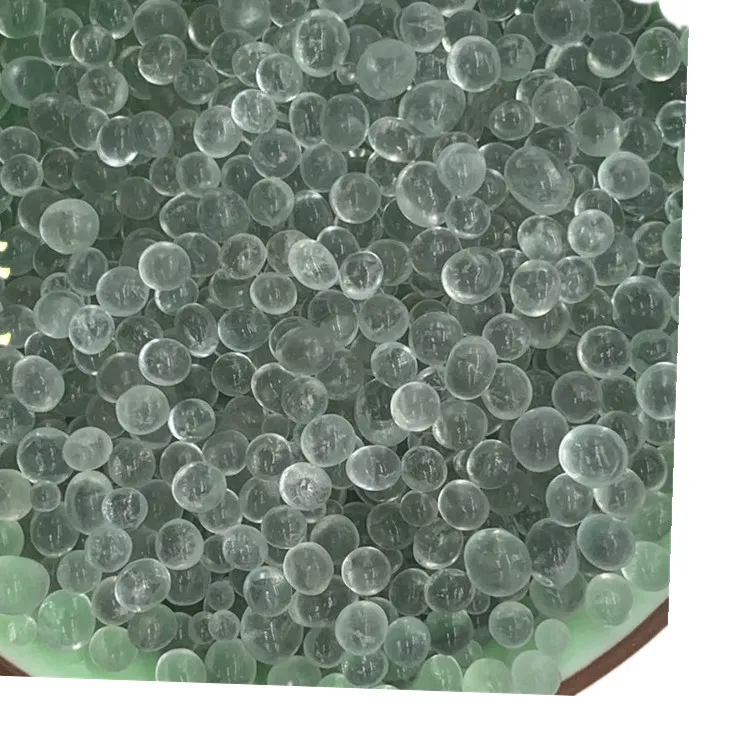

Hollow glass beads are tiny, hollow glass spheres,

Hollow glass microsphere is a kind of small hollow glass sphere, which belongs to inorganic non-metallic material. Typical particle size range 10-180 microns, bulk density 0.1-0.25 grams/cubic centimeter, with light weight, low thermal conductivity, sound insulation, high dispersion, electrical insulation and good thermal stability and other advantages, is a widely used, excellent performance of a new lightweight material developed since 2008. · Pure white color. It can be widely used in any products that have requirements for appearance color.

· Light weight and large volume. The density of hollow glass beads is about one-tenth of the density of traditional filling particles, which can greatly reduce the base weight of the product, replace and save more production resin, and reduce product costs.

· Organic modified (lipophilic) surface. Hollow glass beads are easy to moisten and disperse, and can be filled in most thermosetting thermoplastic resins, such as polyester, epoxy resin, polyurethane, etc.

- High dispersion, good liquidity. Because the hollow glass microbeads are tiny balls, they have better fluidity in the liquid resin than flaky, needle-like or irregularly shaped fillers, so the mold filling performance is excellent. More importantly, this small microbead is isotropic, so it will not cause inconsistent shrinkage rates in different parts due to orientation, ensuring that the size of the product is stable and will not warp.

· Low heat insulation, sound insulation, insulation and water absorption. The inside of the hollow glass microbeads is a thin gas, so it has the characteristics of sound insulation and heat insulation, and is an excellent filler for various thermal insulation and sound insulation products. The thermal insulation properties of the hollow glass beads can also be used to protect the product from thermal shock caused by alternating changes between acute heat and acute cold conditions. The high specific resistance and very low water absorption make it widely used in the production of cable insulation materials.

· Low oil absorption. The particle of the ball determines that it has the smallest specific surface area and low oil absorption rate, which can greatly reduce the amount of resin in the process of use, and the viscosity will not increase much even under the premise of high addition amount, which greatly improves the production operating conditions and can increase the production efficiency by 10% to 20%.

Share

-

Chlorolite is obtained from zeolite ore by high temperature sintering and dehydration treatment.NewsMay.24,2024

-

The main component of talc is magnesium silicate containing talc water,NewsMay.22,2024

-

Alumina is a high-hardness compound commonly used in the manufacture of refractory materials.NewsMay.20,2024

-

Hollow glass beads are tiny, hollow glass spheres,NewsMay.16,2024

-

Fused quartz is the amorphous (glassy) state of silicon oxide (quartz, silica).NewsMay.09,2024

-

Vermiculite is a natural, inorganic, non-toxic mineral that expands under high temperature.NewsApr.09,2024