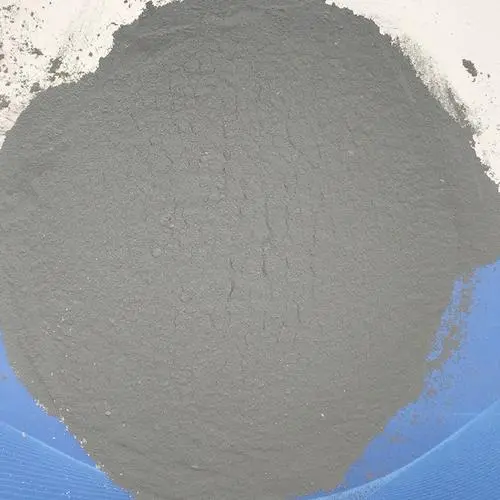

Microsilica powder is a new kind of material,

1.the application of concrete industry doped micro-silica powder concrete has the characteristics of high strength, good adhesion and cohesion performance and can increase the molding thickness. In water conservancy and hydropower projects such as long-span bridge and offshore oil drilling platform, the concrete doped with micro-silica powder can improve its seepage resistance, corrosion resistance and impact wear resistance. In the process of road construction, micro-silica powder can improve the early strength and wear resistance of concrete to a large extent.

2.As an admixture of cement

The strength of cement increases significantly with the increase of the content of micro-silica powder. Micro-silica powder can effectively improve the compactness and secant elastic modulus of cement, and significantly improve the corrosion resistance and creep of cement, but the water absorption rate and volume mass of cement will decrease. Therefore, when the micro-silica powder is incorporated into the cement, it is necessary to pay attention to the problem of water absorption and volume mass reduction.

3. the application in the refractory industry micro-silicon dust has high refractoriness and other excellent properties, is widely used in the refractory industry, mainly used to prepare high temperature ceramics, ladle materials, high temperature wear-resistant materials, breathable bricks, refractory castable and so on. Wang Tao et al. prepared high-purity porous mullite ceramics by using micro-silica powder through pressure-free sintering and gel injection molding under the condition that the molar ratio of A12O3 and SiO2 was 3:2.5 and the sintering temperature was 1450℃. The compressive strength and porosity were 260.93MPa and 21%, respectively. It can be seen that micro-silica powder can improve the fluidity, bulk density and strength of refractory materials, improve the cohesiveness and high temperature performance of refractory materials, extend the service life of refractory materials, and realize the internal digestion and clean production of dust in ferrosilicon and industrial silicon smelting enterprises.

4.the application of metallurgical pellets

In the metallurgical industry, most enterprises use micro-silicon powder as a return material. Although this can reduce the environmental pollution caused by micro-silicon powder, but did not make full use of the magic properties of micro-silicon powder, this is an extensive application, in metallurgical utilization, should pay more attention to its high value-added use.

5. in the chemical industry, composite materials and other applications

The preparation of silica by micro-silica dust mainly focuses on the preparation process, product purity and performance control, etc. However, the product produced is precipitated silica, and the performance gap between the silica produced by vapor phase method is large. There are few research reports on the efficient conversion of soluble silicon by micro-silica powder and the preparation of high value-added food-grade white carbon black by micro-silica dust (fumed white carbon black).

Share

-

Chlorolite is obtained from zeolite ore by high temperature sintering and dehydration treatment.NewsMay.24,2024

-

The main component of talc is magnesium silicate containing talc water,NewsMay.22,2024

-

Alumina is a high-hardness compound commonly used in the manufacture of refractory materials.NewsMay.20,2024

-

Hollow glass beads are tiny, hollow glass spheres,NewsMay.16,2024

-

Fused quartz is the amorphous (glassy) state of silicon oxide (quartz, silica).NewsMay.09,2024

-

Vermiculite is a natural, inorganic, non-toxic mineral that expands under high temperature.NewsApr.09,2024