Kaolin is a kind of clay and clay rock dominated by kaolinite group clay minerals.

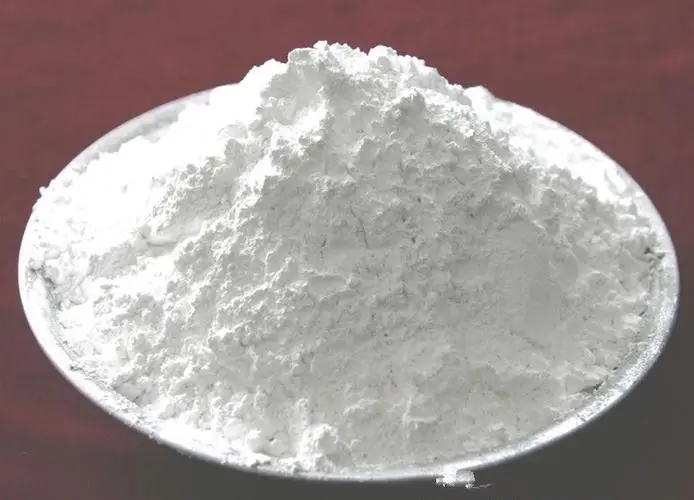

Kaolin is a kind of non-metallic mineral. It is a kind of clay and clay rock dominated by kaolinite group clay minerals. Because of its white and delicate, also known as dolomite. It is named after Gaoling Village, Jingdezhen, Jiangxi Province.

Its pure kaolin is white, delicate, soft soil, with good plasticity and fire resistance and other physical and chemical properties. Its mineral composition is mainly composed of kaolinite, Eloite, hydromica, illite, montmorillonite, quartz, feldspar and other minerals. Kaolin is widely used, mainly for paper making, ceramics and refractory materials, followed by paint, rubber fillers, enamel glaze and white cement raw materials, a small amount of plastic, paint, pigments, grinding wheels, pencils, daily cosmetics, soap, pesticides, medicine, textile, petroleum, chemical, building materials, national defense and other industrial sectors.

The functions of kaolin are: can be used as the main raw material for ceramic production, can be used for paper fillers and coatings, can be used for melting optical glass and glass fiber crucible and laboratory crucible, can be used as a reinforcing agent and filler, as a catalyst for petroleum cracking.

1, kaolin plasticity, cohesiveness, certain dry strength, sintering and burning whiteness and other special properties, make it become the main raw materials for ceramic production, for the production of daily ceramics, building and sanitary ceramics, electric porcelain, chemical corrosion resistant ceramics, arts and crafts ceramics and special ceramics.

2, white, soft, high dispersion, adsorption and chemical flexibility and other excellent process properties, so that it has been widely used in the paper industry. Used for paper fillers and coatings, improve the density, whiteness and smoothness of paper, improve printing performance, reduce papermaking costs.

3, the refractoriness is higher than or equal to 1770 degrees Celsius of pure kaolin, can be made of optical glass and glass fiber crucible and laboratory crucible, low grade kaolin can be made of refractory bricks, saggar, refractory mud, iron mud plug and firing white cement.

4, used as a reinforcing agent and filler, can improve the mechanical strength and acid resistance of rubber, improve product performance, reduce costs.

5, the production of high efficiency adsorbent, instead of synthetic chemical molecular sieve, used as a catalyst for oil cracking.

Share

-

Volcanic stone has high strength, acid and alkali resistance, corrosion resistance and so on.NewsFeb.26,2024

-

Kaolin is a kind of clay and clay rock dominated by kaolinite group clay minerals.NewsFeb.23,2024

-

Complete range of mica/composite rock sheet/dyed mica.NewsJan.26,2024

-

Factory direct landscaping mulch grinding pine barkNewsJan.24,2024

-

Iron powder is one of the most important metal powdersNewsJan.22,2024

-

Bentonite cat litter is mainly used for making cat litter, which absorbs water quicklyNewsJan.19,2024