1 月 . 24, 2025 04:39

Back to list

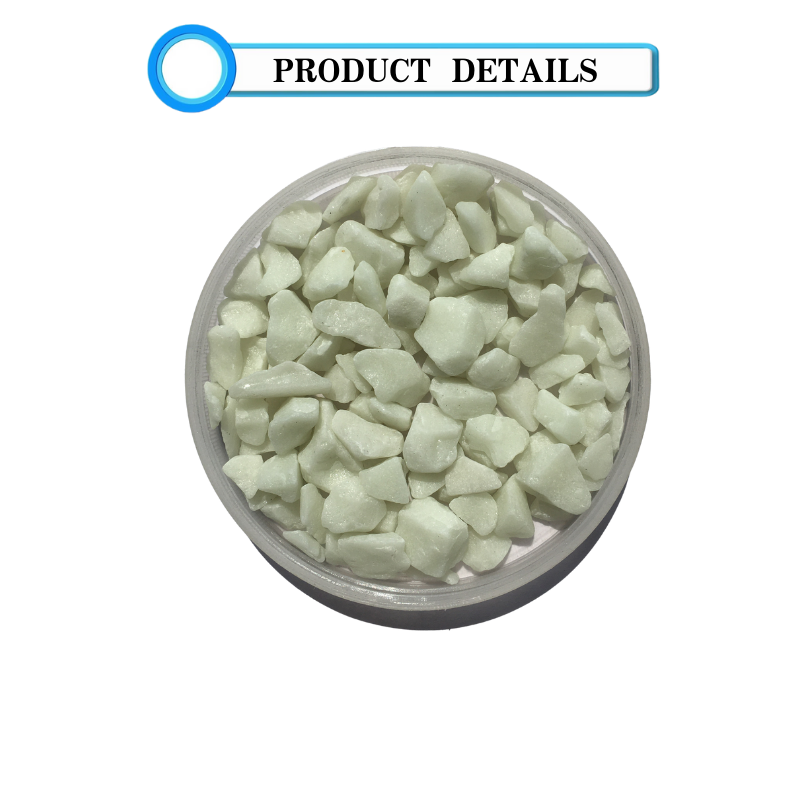

Chlorzeolite powder for feed industry in wastewater treatment for ammonia nitrogen removal

Navigating the landscape of industrial materials can be a daunting endeavor, especially when it comes to bulk zeolite. Zeolite, a naturally occurring mineral with a highly porous structure, has gained prominence in various industries, from environmental engineering to agriculture. Its unique characteristics make it an invaluable asset, yet to leverage its full potential requires a deep understanding of its properties, applications, and procurement considerations.

Authoritativeness stems from a well-documented history of successful implementations across various industrial sectors. In the petrochemical industry, bulk zeolite catalysts play a pivotal role in fluid catalytic cracking, a process critical for converting crude oil into valuable fuel products. Such high-stakes applications require materials that have been rigorously tested and validated by industry standards. Published case studies and peer-reviewed research consistently reaffirm the advantages of using zeolite over conventional catalysts, citing improved yield ratios and sustainability benchmarks. Trustworthiness in sourcing bulk zeolite cannot be overstated. With the mineral's demand on the rise, the market has seen an influx of suppliers, not all of whom meet stringent quality criteria. Engaging with reputable suppliers who adhere to ecological and safety standards ensures that the zeolite procured is not only effective but also ethically sourced. Enterprises are advised to seek suppliers with ISO certifications and a proven track record, as evidenced by client testimonials and repeat business relationships. Trust is also built through transparency in supply chain practices and prompt customer support, crucial for addressing concerns related to product shipping and handling. In conclusion, optimizing the use of bulk zeolite requires a holistic approach that encompasses extensive experience, specialized expertise, recognized authority, and reliable trustworthiness. When these elements coalesce, industries stand to benefit from zeolite's unparalleled capabilities. As businesses across the globe continue to prioritize efficiency and sustainability, the importance of integrating zeolite into their processes is becoming increasingly apparent. By embracing this mineral's full potential, companies can achieve significant advancements in operational performance and environmental responsibility, setting new standards in industrial material utilization.

Authoritativeness stems from a well-documented history of successful implementations across various industrial sectors. In the petrochemical industry, bulk zeolite catalysts play a pivotal role in fluid catalytic cracking, a process critical for converting crude oil into valuable fuel products. Such high-stakes applications require materials that have been rigorously tested and validated by industry standards. Published case studies and peer-reviewed research consistently reaffirm the advantages of using zeolite over conventional catalysts, citing improved yield ratios and sustainability benchmarks. Trustworthiness in sourcing bulk zeolite cannot be overstated. With the mineral's demand on the rise, the market has seen an influx of suppliers, not all of whom meet stringent quality criteria. Engaging with reputable suppliers who adhere to ecological and safety standards ensures that the zeolite procured is not only effective but also ethically sourced. Enterprises are advised to seek suppliers with ISO certifications and a proven track record, as evidenced by client testimonials and repeat business relationships. Trust is also built through transparency in supply chain practices and prompt customer support, crucial for addressing concerns related to product shipping and handling. In conclusion, optimizing the use of bulk zeolite requires a holistic approach that encompasses extensive experience, specialized expertise, recognized authority, and reliable trustworthiness. When these elements coalesce, industries stand to benefit from zeolite's unparalleled capabilities. As businesses across the globe continue to prioritize efficiency and sustainability, the importance of integrating zeolite into their processes is becoming increasingly apparent. By embracing this mineral's full potential, companies can achieve significant advancements in operational performance and environmental responsibility, setting new standards in industrial material utilization.

Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025