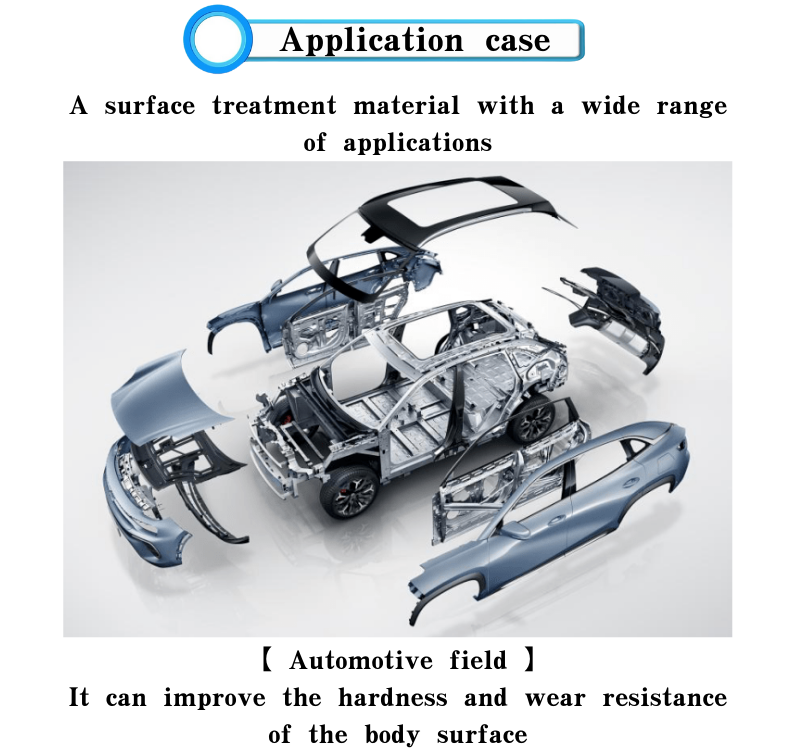

Application

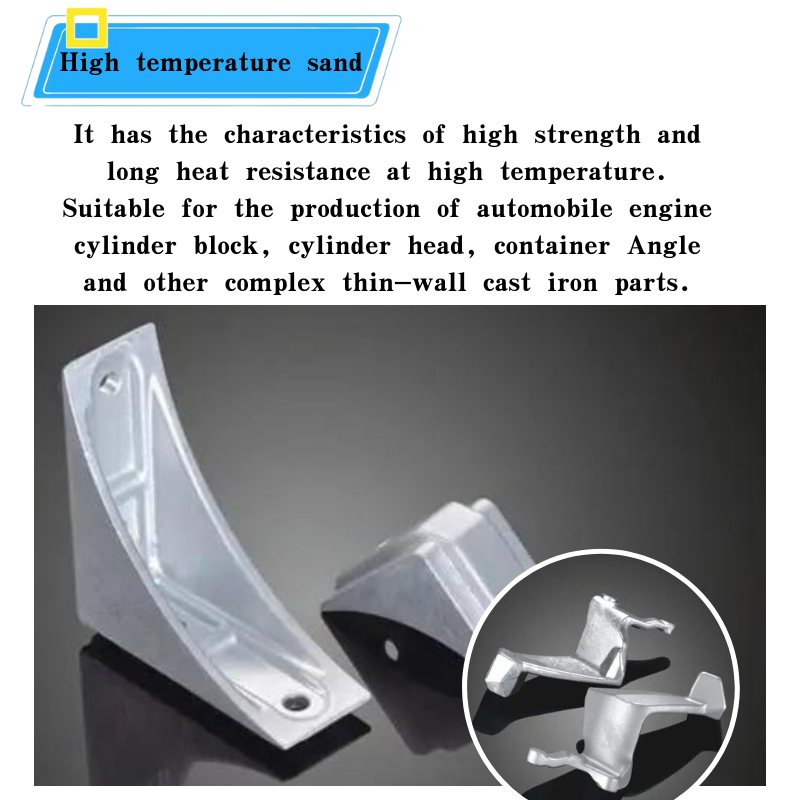

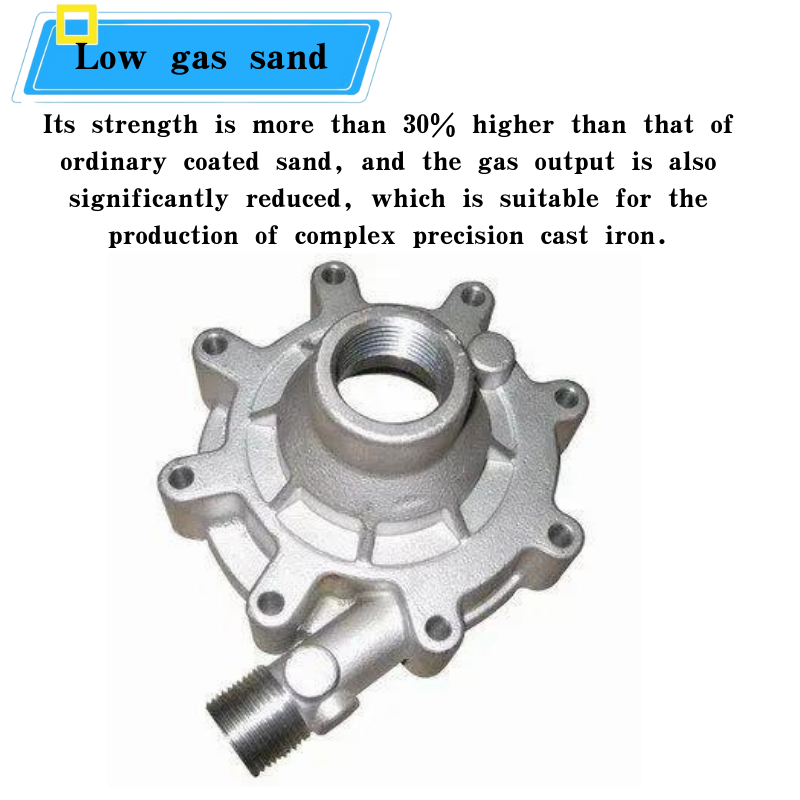

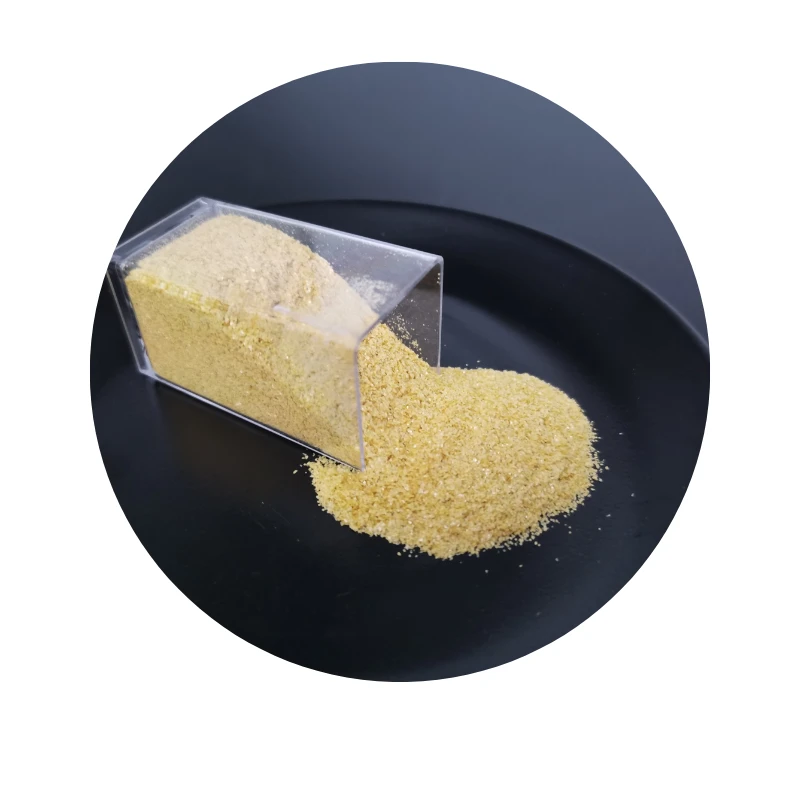

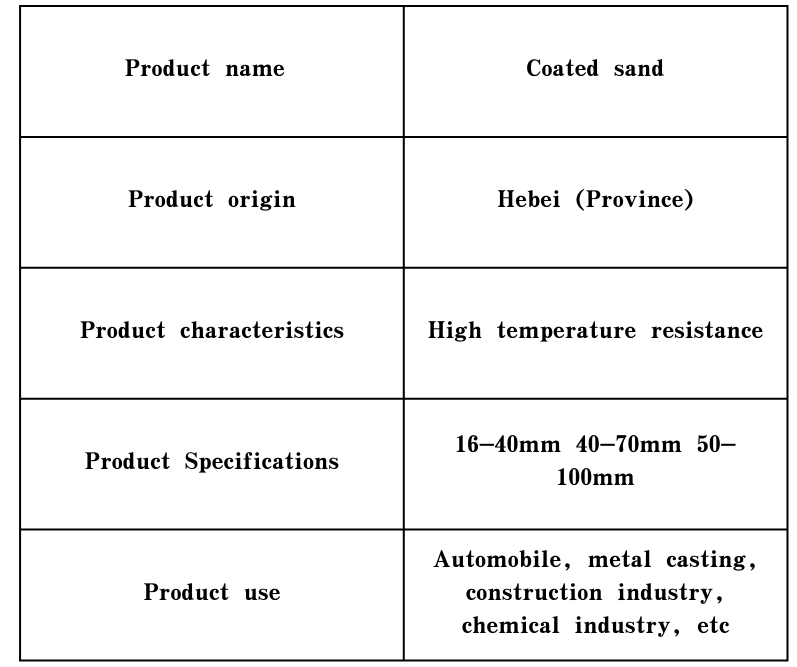

Coated sand. The surface of the sand particles is covered with a layer of solid resin film molding sand or core sand before molding. There are two coating processes: cold method and hot method: the cold method uses ethanol to dissolve the resin, and urotropine is added during the sand mixing process to coat the two on the surface of the sand grains, and the ethanol volatilizes to obtain the coated sand; The method preheats the sand to a certain temperature, adds resin to melt, stirs to coat the surface of the sand particles, adds urotropine water solution and lubricant, cools, breaks, and sieving to obtain coated sand. Used for steel castings and iron castings.Coated sand is a kind of resin coated sand with high quality and selected natural sand as sand base, through special performance resin coating system and ideal process technology. According to the technical requirements of different users, it strives to perfect the combination of room temperature performance, high temperature performance, collapsibility, fluidity, casting surface roughness and so on. It is widely used in automobile engines, diesel engines, hydraulic parts, steel castings, iron castings, etc Copper casting and aluminum casting and other industries.

Main features

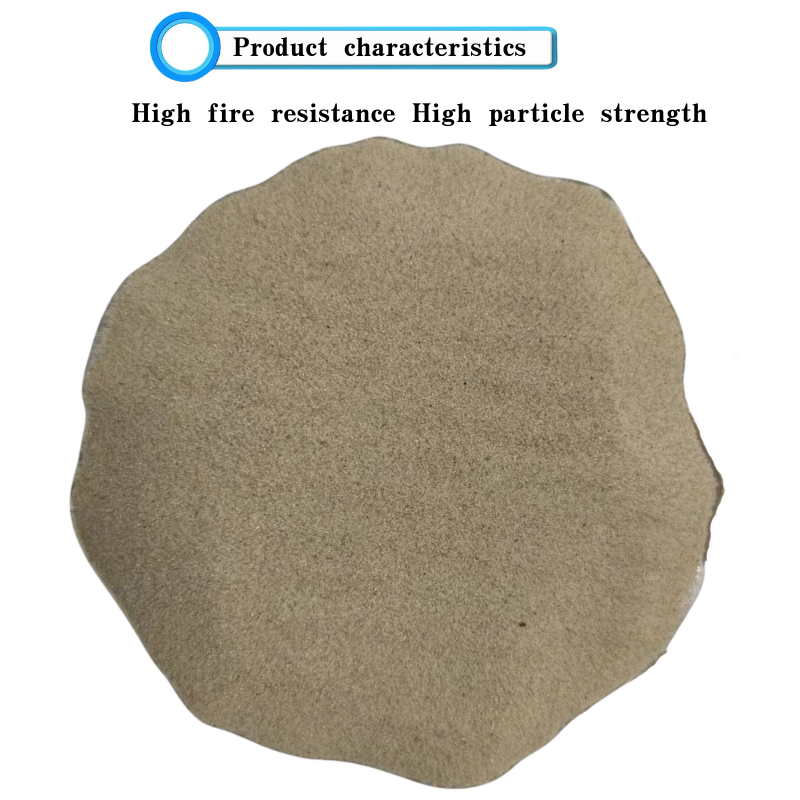

1. vibration cleaning, high strength, low gas, low expansion :

2. good dispersion, high surface finish of the casting;

3. shell type no layer, good thermal stability, good thermal conductivity, good fluidity, casting surface flat;

4. high strength, high temperature resistance, low expansion, good mold release, good sand resistance;

- 5.The shell layer is uniform and does not peel,and the curing speed is fast:

-

Coated sand. The surface of the sand particles is covered with a layer of solid resin film molding sand or core sand before molding. There are two coating processes: cold method and hot method: the cold method uses ethanol to dissolve the resin, and urotropine is added during the sand mixing process to coat the two on the surface of the sand grains, and the ethanol volatilizes to obtain the coated sand; The method preheats the sand to a certain temperature, adds resin to melt, stirs to coat the surface of the sand particles, adds urotropine water solution and lubricant, cools, breaks, and sieving to obtain coated sand. Used for steel castings and iron castings.

Coated sand is a kind of resin coated sand with high quality and selected natural sand as sand base, through special performance resin coating system and ideal process technology. According to the technical requirements of different users, it strives to perfect the combination of room temperature performance, high temperature performance, collapsibility, fluidity, casting surface roughness and so on. It is widely used in automobile engines, diesel engines, hydraulic parts, steel castings, iron castings, etc Copper casting and aluminum casting and other industries.