Utilizing Custom Silica Fume and Fly Ash to Enhance Concrete Production in Factories

The Role of Custom Silica Fume and Fly Ash in Concrete Production

In the modern construction industry, achieving high-quality concrete with improved performance characteristics is a significant challenge. As environmental concerns grow and sustainability becomes increasingly important, the use of supplementary cementitious materials (SCMs) such as silica fume and fly ash has emerged as a popular solution. Both materials can enhance concrete's mechanical and durability properties while contributing to environmentally friendly practices. This article explores the roles of custom silica fume and fly ash in concrete factories and their benefits to the construction industry.

Understanding Silica Fume and Fly Ash

Silica fume, a byproduct of silicon metal and ferrosilicon alloy production, consists of extremely fine particles of silicon dioxide. These particles contribute to improved packing density, resulting in a denser microstructure with fewer voids. Fly ash, on the other hand, is a byproduct of coal combustion in power plants. It typically contains silica, alumina, and iron, which can react with lime in the presence of water to form cementitious compounds. Both materials offer unique benefits that when utilized appropriately, can significantly enhance concrete properties.

Advantages of Using Custom Silica Fume

Custom silica fume provides concrete with several key advantages. Its high pozzolanic activity enhances strength, durability, and resistance to chemical attacks. When incorporated into concrete mixes, silica fume increases the compressive strength and reduces permeability, making concrete less susceptible to water ingress and corrosion of reinforcing steel.

Moreover, silica fume can contribute to reduced shrinkage and improved workability. The finer particles fill voids within the concrete matrix, resulting in a smoother finish. Custom formulations of silica fume can be tailored for specific project requirements, allowing concrete producers to optimize performance characteristics based on application needs.

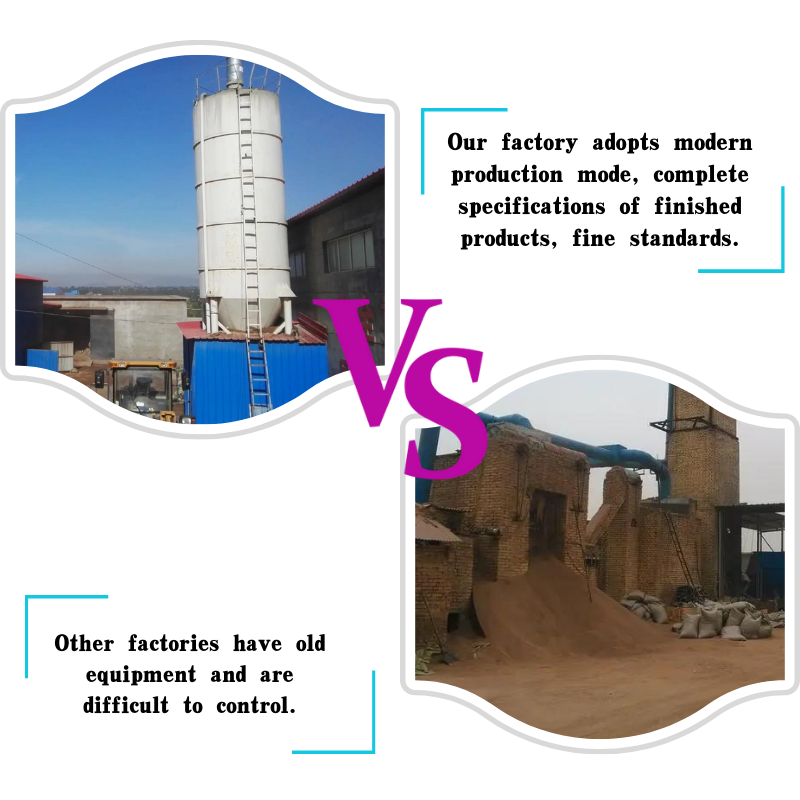

custom silica fume and fly ash in concrete factory

The Benefits of Fly Ash in Concrete

Fly ash's inclusion in concrete not only contributes to stronger and durable mixes but also improves sustainability. Replacing a portion of Portland cement with fly ash reduces the overall carbon footprint of the concrete, as cement production is a significant source of CO2 emissions. This transition is vital in achieving a greener construction process.

Additionally, fly ash enhances the workability and pumpability of concrete, making it easier to handle, especially in large-scale constructions. It also helps in controlling the heat of hydration, making fly ash-based concrete suitable for mass concrete applications, where temperature differentials could lead to cracking.

The Synergistic Effects of Combining Silica Fume and Fly Ash

When silica fume and fly ash are used in tandem, the benefits multiply. This combination can lead to concrete with exceptional properties, including increased long-term strength, improved resistance to alkali-silica reaction (ASR), and enhanced durability against sulfate attacks. The synergy between these materials helps create a balanced mix design that optimizes performance while maintaining cost-effectiveness.

Conclusion

Incorporating custom silica fume and fly ash into concrete production signifies a step toward innovative and sustainable construction practices. As concrete factories increasingly recognize the advantages of these supplementary materials, they are poised to meet both performance and environmental goals more effectively. With continuous advancements in concrete technology and increasing awareness of sustainability, the future of concrete production lies in the intelligent use of silica fume and fly ash, paving the way for a more durable, resilient, and eco-friendly built environment.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025