6 月 . 19, 2024 02:35

Back to list

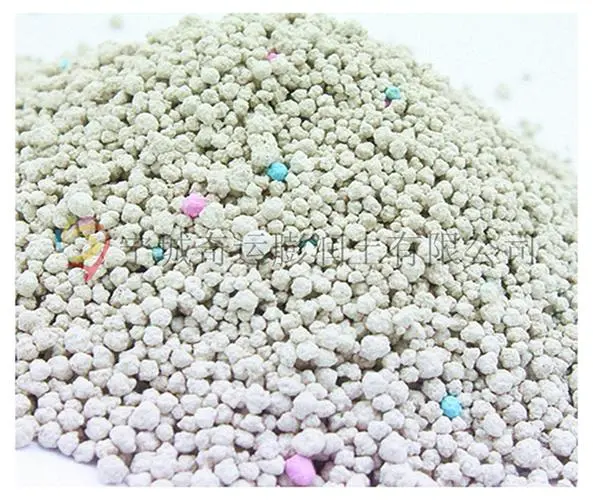

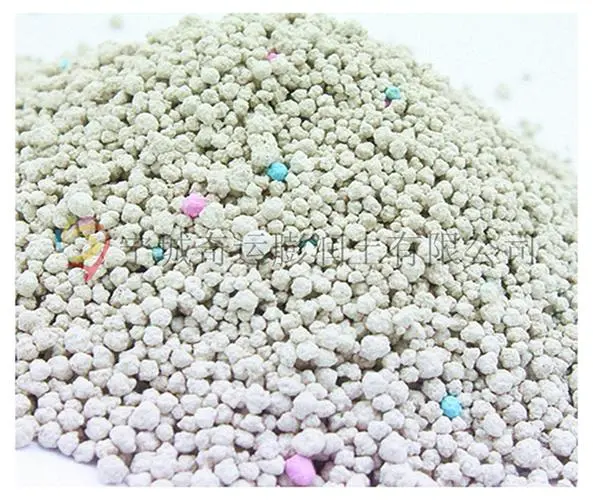

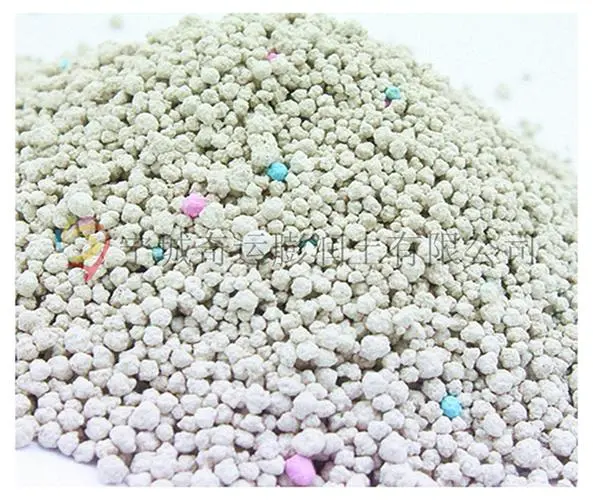

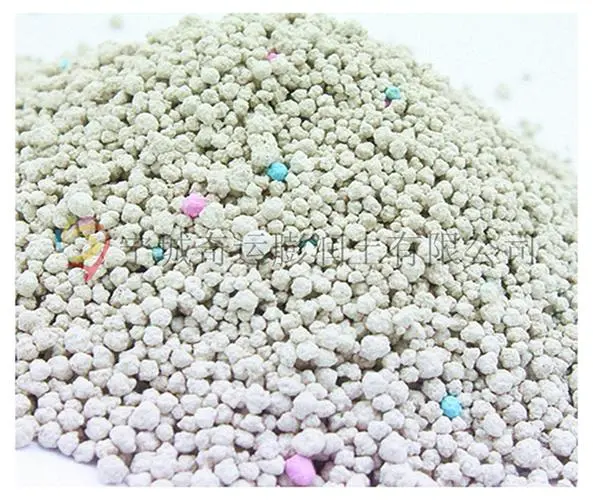

Using glass bead blasting for surface treatment.

The Art and Science of Glass Bead Blasting A Versatile Surface Treatment Technique

Glass bead blasting, a technique that harnesses the power of tiny glass beads to refine and modify surfaces, has gained significant traction in various industries due to its efficacy and versatility. This innovative process, often referred to as glass bead peening or media blasting, combines the elegance of art with the precision of science.

At its core, glass bead blasting involves propelling a mixture of compressed air and spherical glass beads onto a surface. These beads, typically made from recycled glass, range in size from 10 to 400 microns, providing a wide scope for different finishing effects. The process is non-abrasive, meaning it doesn't significantly alter the material's structural integrity, making it suitable for delicate materials like metals, plastics, and even glass itself.

The science behind glass bead blasting lies in the impact these beads have on the surface. Upon contact, they create a peening effect, compressing the outer layer and leaving a smooth, satin finish. This not only enhances the aesthetic appeal but also improves the surface's resistance to corrosion and wear. Moreover, due to their spherical shape, glass beads do not create sharp edges or burrs, ensuring a safe and uniform finish.

In the world of art, glass bead blasting has opened up new avenues for creative expression. Artists can now etch intricate designs, patterns, and textures onto glass, metal, or other surfaces, adding depth and dimension to their work Artists can now etch intricate designs, patterns, and textures onto glass, metal, or other surfaces, adding depth and dimension to their work Artists can now etch intricate designs, patterns, and textures onto glass, metal, or other surfaces, adding depth and dimension to their work Artists can now etch intricate designs, patterns, and textures onto glass, metal, or other surfaces, adding depth and dimension to their work

Artists can now etch intricate designs, patterns, and textures onto glass, metal, or other surfaces, adding depth and dimension to their work Artists can now etch intricate designs, patterns, and textures onto glass, metal, or other surfaces, adding depth and dimension to their work glass beads blasting. The technique allows for both fine detailing and large-scale projects, making it adaptable to diverse artistic visions.

In industrial applications, glass bead blasting finds use in everything from automotive restoration to aerospace manufacturing. It's an effective method for cleaning and degreasing engine parts, removing paint or rust from metal surfaces, and preparing surfaces for painting or coating. Its non-conductive properties make it ideal for use in electronic components where static electricity could be a concern.

Moreover, the recyclable nature of glass beads makes this process environmentally friendly. After use, the beads can be collected, cleaned, and reused multiple times, minimizing waste and reducing environmental impact.

In conclusion, glass bead blasting is a testament to the harmonious blend of technology and creativity. It offers a gentle yet powerful means of surface treatment, transforming mundane materials into works of art or high-performance industrial components. As technology continues to evolve, so does the potential of glass bead blasting, solidifying its position as a go-to technique in various industries.

glass beads blasting. The technique allows for both fine detailing and large-scale projects, making it adaptable to diverse artistic visions.

In industrial applications, glass bead blasting finds use in everything from automotive restoration to aerospace manufacturing. It's an effective method for cleaning and degreasing engine parts, removing paint or rust from metal surfaces, and preparing surfaces for painting or coating. Its non-conductive properties make it ideal for use in electronic components where static electricity could be a concern.

Moreover, the recyclable nature of glass beads makes this process environmentally friendly. After use, the beads can be collected, cleaned, and reused multiple times, minimizing waste and reducing environmental impact.

In conclusion, glass bead blasting is a testament to the harmonious blend of technology and creativity. It offers a gentle yet powerful means of surface treatment, transforming mundane materials into works of art or high-performance industrial components. As technology continues to evolve, so does the potential of glass bead blasting, solidifying its position as a go-to technique in various industries.

Artists can now etch intricate designs, patterns, and textures onto glass, metal, or other surfaces, adding depth and dimension to their work Artists can now etch intricate designs, patterns, and textures onto glass, metal, or other surfaces, adding depth and dimension to their work

Artists can now etch intricate designs, patterns, and textures onto glass, metal, or other surfaces, adding depth and dimension to their work Artists can now etch intricate designs, patterns, and textures onto glass, metal, or other surfaces, adding depth and dimension to their work glass beads blasting. The technique allows for both fine detailing and large-scale projects, making it adaptable to diverse artistic visions.

In industrial applications, glass bead blasting finds use in everything from automotive restoration to aerospace manufacturing. It's an effective method for cleaning and degreasing engine parts, removing paint or rust from metal surfaces, and preparing surfaces for painting or coating. Its non-conductive properties make it ideal for use in electronic components where static electricity could be a concern.

Moreover, the recyclable nature of glass beads makes this process environmentally friendly. After use, the beads can be collected, cleaned, and reused multiple times, minimizing waste and reducing environmental impact.

In conclusion, glass bead blasting is a testament to the harmonious blend of technology and creativity. It offers a gentle yet powerful means of surface treatment, transforming mundane materials into works of art or high-performance industrial components. As technology continues to evolve, so does the potential of glass bead blasting, solidifying its position as a go-to technique in various industries.

glass beads blasting. The technique allows for both fine detailing and large-scale projects, making it adaptable to diverse artistic visions.

In industrial applications, glass bead blasting finds use in everything from automotive restoration to aerospace manufacturing. It's an effective method for cleaning and degreasing engine parts, removing paint or rust from metal surfaces, and preparing surfaces for painting or coating. Its non-conductive properties make it ideal for use in electronic components where static electricity could be a concern.

Moreover, the recyclable nature of glass beads makes this process environmentally friendly. After use, the beads can be collected, cleaned, and reused multiple times, minimizing waste and reducing environmental impact.

In conclusion, glass bead blasting is a testament to the harmonious blend of technology and creativity. It offers a gentle yet powerful means of surface treatment, transforming mundane materials into works of art or high-performance industrial components. As technology continues to evolve, so does the potential of glass bead blasting, solidifying its position as a go-to technique in various industries. Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025