Top Chinese Manufacturers of High-Quality Glass Beads for Various Applications and Industries

The Evolution of Chinese Glass Bead Manufacturers

China has long been recognized as a powerhouse in the manufacturing of various products, and glass beads are no exception. These vibrant and versatile items have found their way into countless applications, from jewelry and fashion to industrial uses and decorative arts. The landscape of Chinese glass bead manufacturing is not only vast but also rich with history and innovation.

Historical Context

The tradition of bead-making in China can be traced back thousands of years. Ancient civilizations created beads from materials such as stone, wood, and bone. With the advent of glass-making technology during the Han Dynasty, glass beads emerged, allowing for more complex designs and vibrant colors. As trade routes expanded, so did the demand for these beautiful items, making China a key player in the global bead market.

Modern Manufacturing Practices

Today, Chinese glass bead manufacturers are at the forefront of the industry, thanks to advanced technology and skilled craftsmanship. The manufacturing process begins with high-quality raw materials, including silica sand, soda ash, and various colorants. The melting process occurs at high temperatures in gas-fueled furnaces, allowing for the creation of molten glass, which is then shaped into beads.

One of the standout aspects of Chinese glass bead production is the variety of techniques employed. From traditional hand-made methods to the latest automated machinery, manufacturers offer a wide range of glass beads, including seed beads, lampwork beads, and crystal beads. Each technique brings a unique character to the beads, appealing to different markets and consumer preferences.

Sustainability Practices

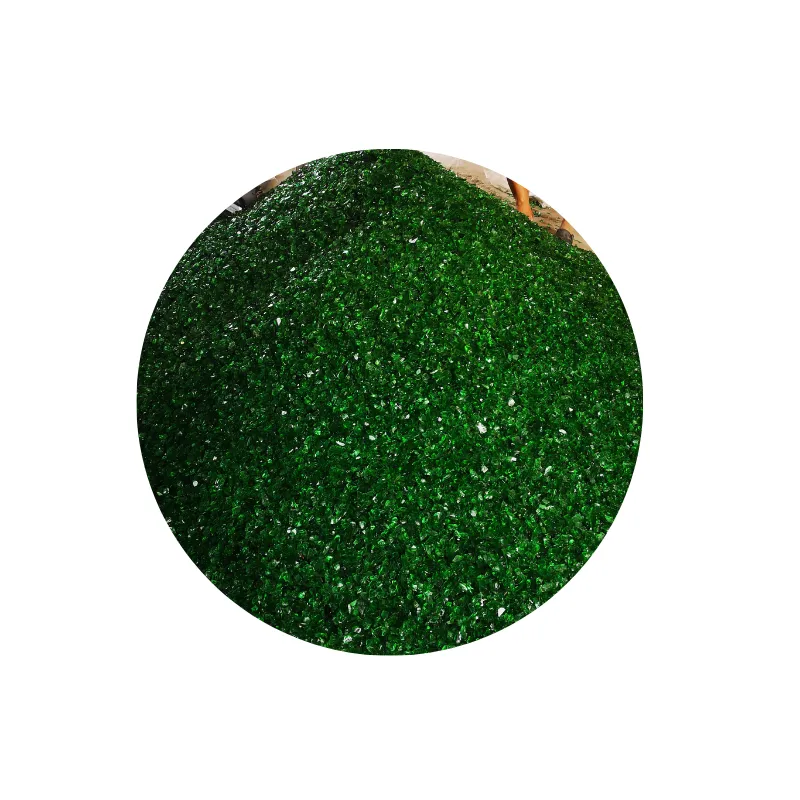

china chinese glass beads manufacturers

In recent years, there has been a growing awareness of environmental sustainability within the manufacturing sector. Chinese glass bead manufacturers have begun adopting eco-friendly practices, such as recycling glass waste and minimizing energy consumption. By using less harmful materials and optimizing production processes, many companies are striving to reduce their carbon footprint while maintaining quality standards.

Global Impact and Market Reach

Chinese glass bead manufacturers export their products to markets all over the world. The diverse applications of glass beads have led to their incorporation in a variety of industries. In fashion, they are widely used in costume jewelry and accessories, often seen in intricate beadwork that adds a touch of elegance to garments. In home decor, glass beads can be found in everything from curtains to decorative vases.

Moreover, the crafting community has embraced Chinese glass beads for DIY projects. The affordability and variety available in the Chinese market provide crafters with endless possibilities for creativity and self-expression. Online marketplaces and craft fairs often showcase the ingenuity of independent artists who use these beads to create unique and stunning pieces.

Challenges and Innovations

Despite the advantages, the Chinese glass bead manufacturing industry faces several challenges, including competition from other countries and market saturation. To remain competitive, manufacturers are focusing on innovation, developing new designs, colors, and finishes that cater to emerging trends. Furthermore, through collaborations with designers and artists, they are able to create exclusive collections that appeal to niche markets.

Conclusion

The evolution of glass bead manufacturing in China is a testament to the country’s ability to blend tradition with modernity. With a rich history and a commitment to innovation and sustainability, Chinese glass bead manufacturers continue to thrive in a global market. As they adapt to changing consumer demands and environmental concerns, the future of glass beads produced in China looks bright, ensuring their place in both craftsmanship and commerce for years to come.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025