Tailored Quartz and Mica Solutions from a Leading Manufacturer for Your Unique Needs

The Specialty of Custom Quartz and Mica Manufacturing

In the realm of material science and manufacturing, quartz and mica hold significant importance due to their unique properties and versatile applications. Custom quartz and mica manufacturing has emerged as a critical service for industries ranging from electronics to construction, catering to specific customer needs and enhancing product quality.

Understanding Quartz and Mica

Quartz, one of the most abundant minerals on Earth, is primarily composed of silicon dioxide. Its crystalline structure provides exceptional hardness and resistance to chemical weathering, making it suitable for a myriad of applications. Mica, on the other hand, is a group of silicate minerals known for their ability to be split into thin, flexible sheets. Mica's excellent electrical insulation properties, thermal stability, and flexibility make it invaluable in electrical and electronic applications.

The Need for Custom Solutions

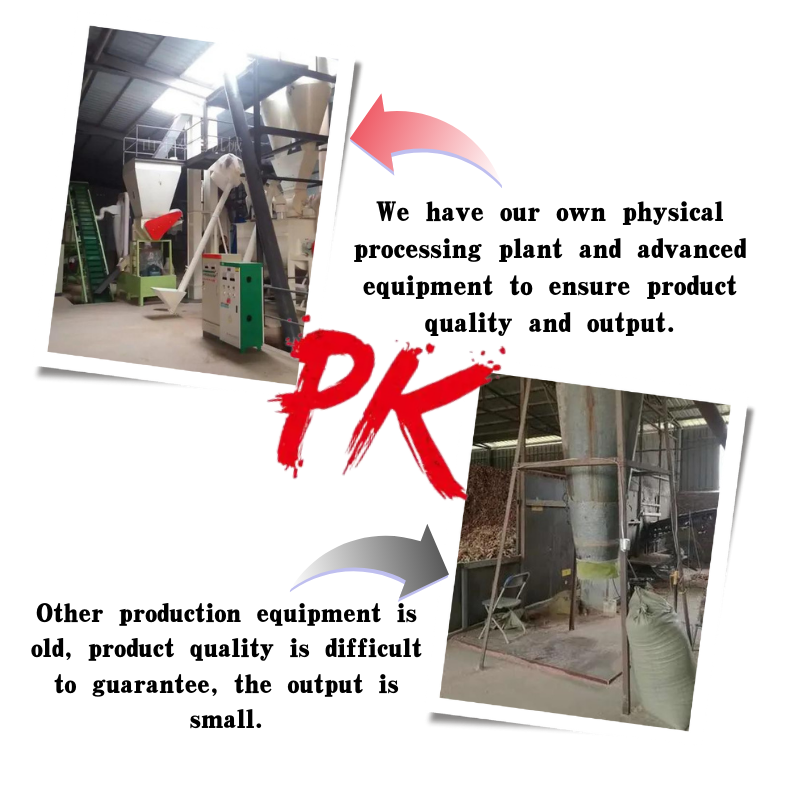

While both quartz and mica are available in standard forms, many industries require customized solutions to meet specific requirements. The demand for tailored products has prompted manufacturers to invest in advanced technologies and processes that allow for the production of quartz and mica in various specifications. Custom manufacturing involves adjusting parameters such as size, purity, and physical properties to create materials that precisely meet the needs of clients.

Applications of Custom Quartz and Mica

1. Electronics In the electronics industry, the linearity and thermal stability of quartz make it an ideal material for components such as oscillators and filters. Custom quartz can be fabricated into specific shapes and sizes for various devices, including smartphones and telecommunications equipment. Similarly, mica is widely used in capacitors, insulators, and heating elements due to its excellent dielectric properties.

custom quartz and mica manufacturer

2. Construction In construction, quartz is used as an aggregate in concrete and other building materials. Custom manufacturing allows builders to specify the size and purity of quartz aggregates to enhance strength and durability. Mica is used in roofing and wallboard materials, providing resistance to heat and moisture while contributing to the aesthetic appeal of buildings.

3. Aerospace and Automotive The aerospace and automotive industries require materials that can withstand extreme conditions. Custom quartz can be tailored to provide optimal performance in high-temperature applications, while mica serves as a lightweight, heat-resistant component in engine parts and thermal interface materials.

4. Cosmetics and Personal Care Quartz and mica are also prevalent in the cosmetics industry, where they are used as fillers in products such as foundations, eye shadows, and other makeup items. Custom mica can be produced in specific particle sizes and colors to achieve desired cosmetic effects, enhancing the product’s marketability.

The Manufacturing Process

The process of custom quartz and mica manufacturing often involves several stages, including sourcing high-quality raw materials, advanced processing techniques such as grinding and milling, and precision fabrication methods. Manufacturers typically utilize state-of-the-art machinery and equipment to ensure consistency and quality in the final products. Quality assurance is crucial at every stage to comply with industry standards and client specifications.

Conclusion

The importance of custom quartz and mica manufacturing cannot be overstated. As industries continue to evolve and demand higher-quality materials, the ability to customize these substances to meet specific requirements will remain a valuable asset. By leveraging advanced technology and a deep understanding of material properties, manufacturers can provide innovative solutions that drive progress across various sectors. Whether for electronic devices, construction materials, or specialty applications, custom quartz and mica manufacturing is set to play a pivotal role in shaping the future of materials science.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025