6 月 . 27, 2024 06:03

Back to list

Suppliers of Wet Fly Ash Premium Quality Manufacturers

Wet Fly Ash Manufacturers Pioneers in Sustainable Building Solutions

In the realm of construction and engineering, wet fly ash manufacturers play a pivotal role in promoting sustainability and eco-friendly practices. Fly ash, a byproduct of coal combustion, is a valuable resource when harnessed correctly, particularly in the production of concrete and other building materials. This article delves into the significance of wet fly ash manufacturers and their contribution to the global green building movement.

Fly ash, specifically wet fly ash, refers to the fine particles that rise with the flue gases during coal combustion in power plants. It is collected using wet collection methods, resulting in a slurry-like substance. Unlike dry fly ash, which is collected through electrostatic precipitators, wet fly ash requires specialized handling and processing, making it an area of expertise for dedicated manufacturers.

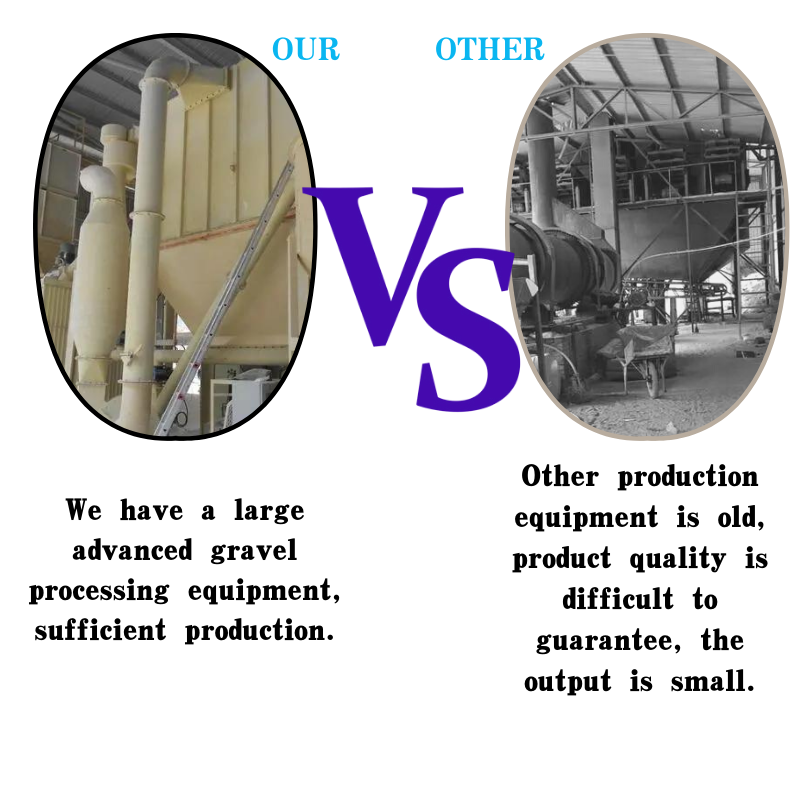

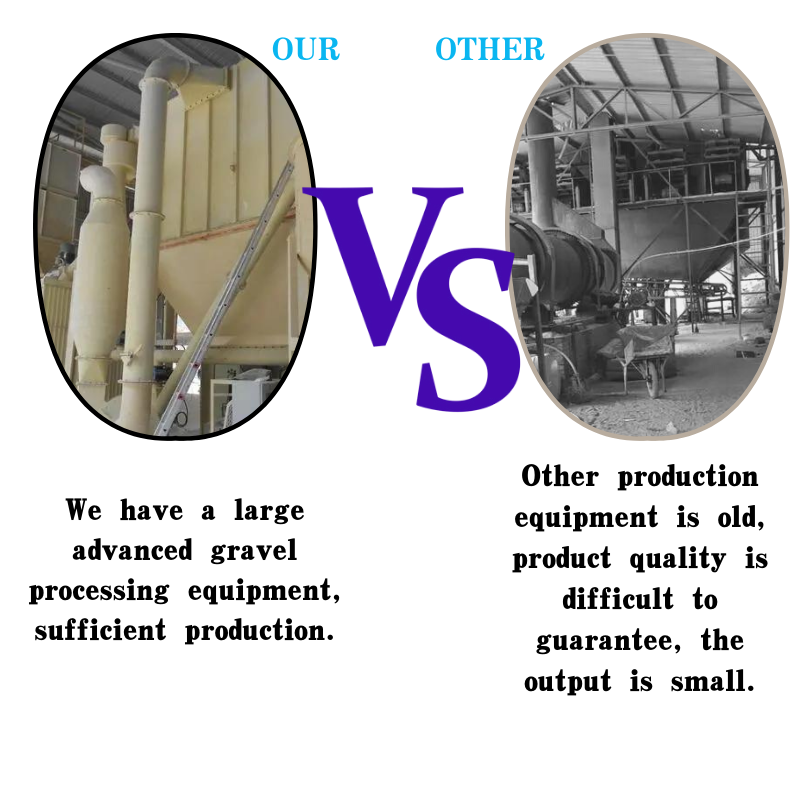

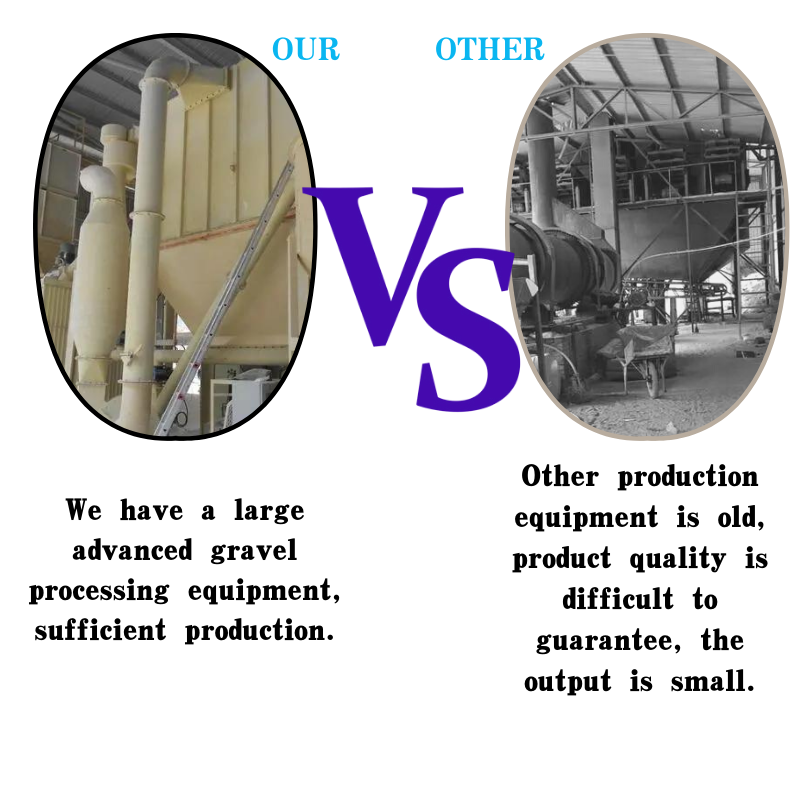

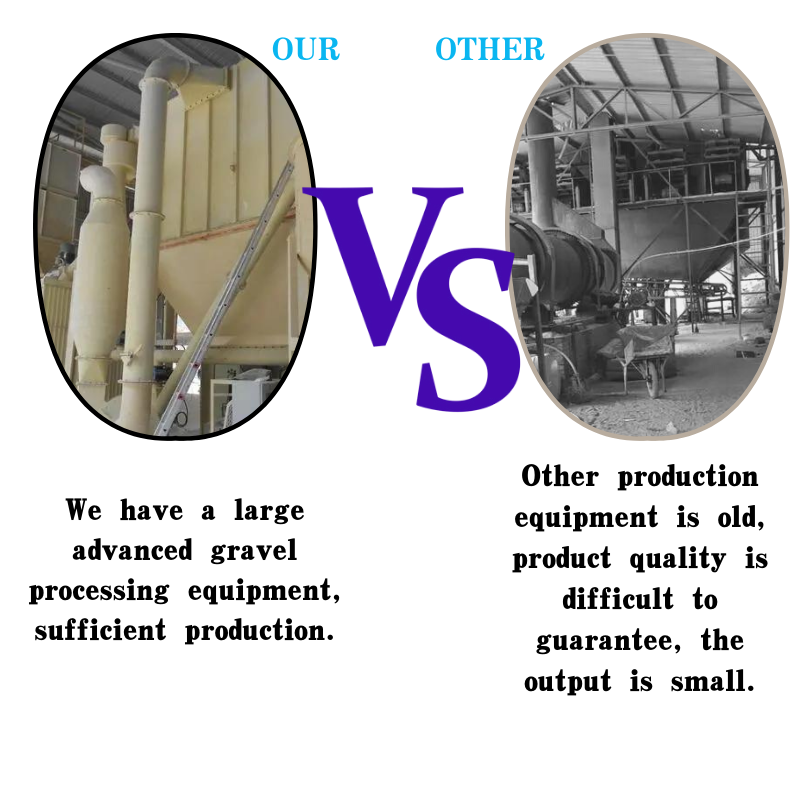

Wet fly ash manufacturers are at the forefront of transforming waste into a resource. They employ advanced technologies to extract, process, and stabilize this waste product, converting it into a high-quality, environmentally friendly construction material. The processed wet fly ash has numerous benefits, including improved workability, enhanced strength, and better durability in concrete, thereby reducing the dependence on traditional cement.

These manufacturers not only contribute to waste reduction but also significantly reduce the carbon footprint of construction projects. By utilizing fly ash, they help divert millions of tons of waste from landfills each year, mitigating environmental pollution By utilizing fly ash, they help divert millions of tons of waste from landfills each year, mitigating environmental pollution By utilizing fly ash, they help divert millions of tons of waste from landfills each year, mitigating environmental pollution By utilizing fly ash, they help divert millions of tons of waste from landfills each year, mitigating environmental pollution

By utilizing fly ash, they help divert millions of tons of waste from landfills each year, mitigating environmental pollution By utilizing fly ash, they help divert millions of tons of waste from landfills each year, mitigating environmental pollution wet fly ash manufacturer. Moreover, the energy saved in the production of cement, a highly energy-intensive process, further contributes to.

The global wet fly ash market is witnessing steady growth due to increasing awareness about sustainable construction and stringent environmental regulations. Manufacturers are investing in research and development to improve the efficiency of their processes and expand the applications of wet fly ash. From road construction to precast concrete products, wet fly ash is finding its way into various segments of the construction industry.

Notably, wet fly ash manufacturers are also collaborating with architects, engineers, and builders to educate them about the benefits of using this eco-friendly material. They provide technical support, training, and customized solutions to ensure optimal use of wet fly ash in construction projects.

In conclusion, wet fly ash manufacturers are integral to the circular economy, bridging the gap between waste management and sustainable construction. Their innovative practices and commitment to environmental stewardship are reshaping the industry's approach to waste and resource utilization. As the world continues to prioritize sustainability, these manufacturers are poised to make a significant impact, driving the transition towards a greener, more responsible future.

wet fly ash manufacturer. Moreover, the energy saved in the production of cement, a highly energy-intensive process, further contributes to.

The global wet fly ash market is witnessing steady growth due to increasing awareness about sustainable construction and stringent environmental regulations. Manufacturers are investing in research and development to improve the efficiency of their processes and expand the applications of wet fly ash. From road construction to precast concrete products, wet fly ash is finding its way into various segments of the construction industry.

Notably, wet fly ash manufacturers are also collaborating with architects, engineers, and builders to educate them about the benefits of using this eco-friendly material. They provide technical support, training, and customized solutions to ensure optimal use of wet fly ash in construction projects.

In conclusion, wet fly ash manufacturers are integral to the circular economy, bridging the gap between waste management and sustainable construction. Their innovative practices and commitment to environmental stewardship are reshaping the industry's approach to waste and resource utilization. As the world continues to prioritize sustainability, these manufacturers are poised to make a significant impact, driving the transition towards a greener, more responsible future.

By utilizing fly ash, they help divert millions of tons of waste from landfills each year, mitigating environmental pollution By utilizing fly ash, they help divert millions of tons of waste from landfills each year, mitigating environmental pollution

By utilizing fly ash, they help divert millions of tons of waste from landfills each year, mitigating environmental pollution By utilizing fly ash, they help divert millions of tons of waste from landfills each year, mitigating environmental pollution wet fly ash manufacturer. Moreover, the energy saved in the production of cement, a highly energy-intensive process, further contributes to.

The global wet fly ash market is witnessing steady growth due to increasing awareness about sustainable construction and stringent environmental regulations. Manufacturers are investing in research and development to improve the efficiency of their processes and expand the applications of wet fly ash. From road construction to precast concrete products, wet fly ash is finding its way into various segments of the construction industry.

Notably, wet fly ash manufacturers are also collaborating with architects, engineers, and builders to educate them about the benefits of using this eco-friendly material. They provide technical support, training, and customized solutions to ensure optimal use of wet fly ash in construction projects.

In conclusion, wet fly ash manufacturers are integral to the circular economy, bridging the gap between waste management and sustainable construction. Their innovative practices and commitment to environmental stewardship are reshaping the industry's approach to waste and resource utilization. As the world continues to prioritize sustainability, these manufacturers are poised to make a significant impact, driving the transition towards a greener, more responsible future.

wet fly ash manufacturer. Moreover, the energy saved in the production of cement, a highly energy-intensive process, further contributes to.

The global wet fly ash market is witnessing steady growth due to increasing awareness about sustainable construction and stringent environmental regulations. Manufacturers are investing in research and development to improve the efficiency of their processes and expand the applications of wet fly ash. From road construction to precast concrete products, wet fly ash is finding its way into various segments of the construction industry.

Notably, wet fly ash manufacturers are also collaborating with architects, engineers, and builders to educate them about the benefits of using this eco-friendly material. They provide technical support, training, and customized solutions to ensure optimal use of wet fly ash in construction projects.

In conclusion, wet fly ash manufacturers are integral to the circular economy, bridging the gap between waste management and sustainable construction. Their innovative practices and commitment to environmental stewardship are reshaping the industry's approach to waste and resource utilization. As the world continues to prioritize sustainability, these manufacturers are poised to make a significant impact, driving the transition towards a greener, more responsible future. Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025