1 月 . 28, 2025 04:52

Back to list

Manufacturers supply micro silica powder construction chemical electronic medicine special

Silica fume and fly ash are increasingly recognized for their essential roles in enhancing the performance and sustainability of modern construction materials. These by-products of industrial processes not only contribute to reducing waste but also significantly improve the structural integrity and longevity of concrete. As a result, choosing the right type and blend of these materials can dramatically affect the outcome of construction projects.

The sustainability aspect of using silica fume and fly ash cannot be overstated. Utilizing these by-products reduces the reliance on landfill disposal and decreases the carbon footprint associated with cement production. This makes these materials highly desirable in green building certifications and environmentally-conscious construction practices. One of the primary considerations when incorporating silica fume and fly ash into concrete is the specific blend ratio, which depends on the intended application and performance requirements. Engineers and contractors must carefully evaluate factors such as the environment's aggressive elements, the desired lifespan of the structure, and the necessary load-bearing capacities. Additionally, proper handling and mixing procedures must be followed to achieve the best results, as improper application can lead to issues such as increased setting times or reduced mechanical properties. Projects worldwide have successfully used silica fume and fly ash, demonstrating their substantial benefits. Notable examples include marine infrastructure, where the low permeability and high structural integrity of such concretes are crucial, as well as high-rise buildings that require reduced weight and increased strength. In conclusion, the integration of silica fume and fly ash into concrete formulations represents a functional and sustainable approach to modern construction. While their applications require technical expertise, the advantages they offer in terms of durability, sustainability, and cost-efficiency make them a compelling choice for forward-thinking projects. Embracing these materials not only enhances the performance of construction projects but also aligns with global sustainability goals, marking a pivotal step toward responsible construction practices.

The sustainability aspect of using silica fume and fly ash cannot be overstated. Utilizing these by-products reduces the reliance on landfill disposal and decreases the carbon footprint associated with cement production. This makes these materials highly desirable in green building certifications and environmentally-conscious construction practices. One of the primary considerations when incorporating silica fume and fly ash into concrete is the specific blend ratio, which depends on the intended application and performance requirements. Engineers and contractors must carefully evaluate factors such as the environment's aggressive elements, the desired lifespan of the structure, and the necessary load-bearing capacities. Additionally, proper handling and mixing procedures must be followed to achieve the best results, as improper application can lead to issues such as increased setting times or reduced mechanical properties. Projects worldwide have successfully used silica fume and fly ash, demonstrating their substantial benefits. Notable examples include marine infrastructure, where the low permeability and high structural integrity of such concretes are crucial, as well as high-rise buildings that require reduced weight and increased strength. In conclusion, the integration of silica fume and fly ash into concrete formulations represents a functional and sustainable approach to modern construction. While their applications require technical expertise, the advantages they offer in terms of durability, sustainability, and cost-efficiency make them a compelling choice for forward-thinking projects. Embracing these materials not only enhances the performance of construction projects but also aligns with global sustainability goals, marking a pivotal step toward responsible construction practices.

Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

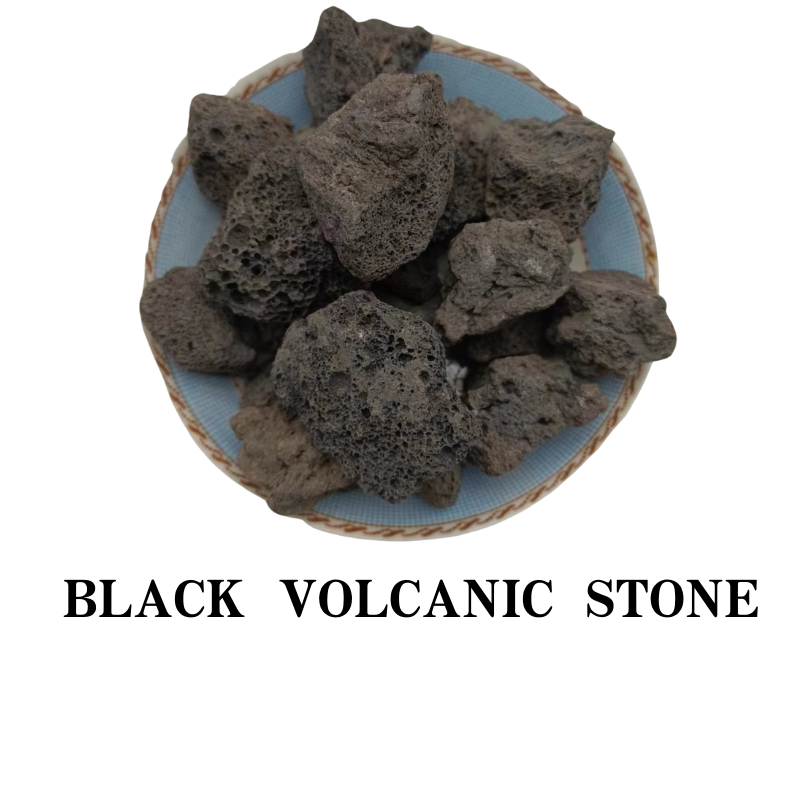

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025