1 月 . 28, 2025 01:47

Back to list

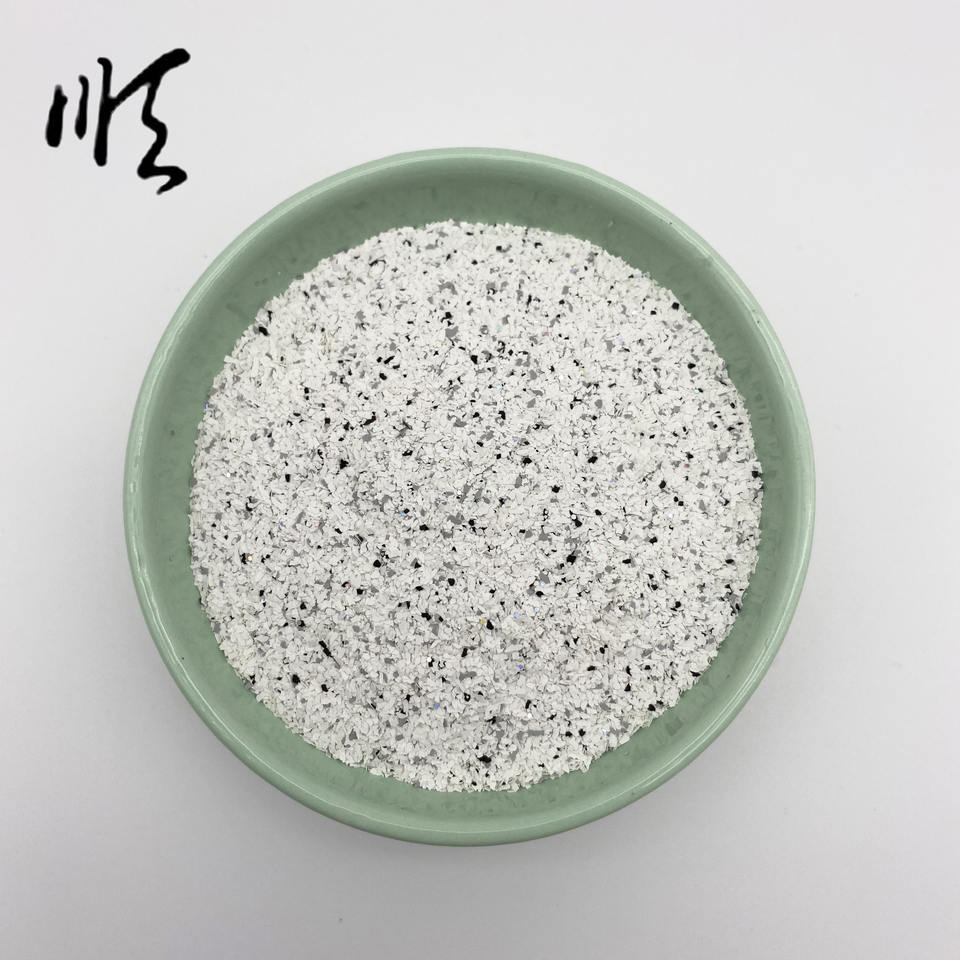

silica fume and fly ash in concrete

In the world of modern construction, the need for sustainable and durable building materials is ever-expanding. Concrete, a staple in construction, has seen significant advancements with the incorporation of supplementary cementitious materials (SCMs) such as silica fume and fly ash. This article delves into the remarkable benefits and real-world applications of these materials in concrete, delivering unique insights grounded in expertise and authority.

In terms of expertise, ongoing research and field trials continually affirm the environmental and performance advantages of these materials. Recent studies have demonstrated that concrete containing both silica fume and fly ash can achieve a synergy, outperforming mixtures containing either component alone. This dual incorporation is known to further enhance the longevity and mechanical properties of concrete, making it a step forward in tackling the sustainability challenges faced by the construction industry. For those concerned with authoritativeness and trustworthiness, the adoption of silica fume and fly ash in concrete is not merely a theoretical proposition but a practice endorsed by leading industry standards such as ASTM and ACI. These organizations have established specifications that assure quality control and compliance when utilizing these materials, providing confidence and security to engineers and builders globally. To fully reap the benefits of silica fume and fly ash, concrete producers and construction professionals must consider key factors such as particle size distribution, replacement levels, and the compatibility with other concrete mix components. Consulting with specialists in concrete mix designs can optimize these elements, ensuring that the resultant concrete not only meets the desired performance criteria but also adheres to sustainability goals. In conclusion, the integration of silica fume and fly ash into concrete mixes represents a quintessential advancement toward greener and more durable construction practices. These materials, backed by solid scientific research and industry validation, offer a dual advantage of enhancing the concrete's physical properties while supporting environmental sustainability initiatives. As the construction landscape continues to evolve, these SCMs stand as cornerstone resources in building a more resilient and eco-friendly future.

In terms of expertise, ongoing research and field trials continually affirm the environmental and performance advantages of these materials. Recent studies have demonstrated that concrete containing both silica fume and fly ash can achieve a synergy, outperforming mixtures containing either component alone. This dual incorporation is known to further enhance the longevity and mechanical properties of concrete, making it a step forward in tackling the sustainability challenges faced by the construction industry. For those concerned with authoritativeness and trustworthiness, the adoption of silica fume and fly ash in concrete is not merely a theoretical proposition but a practice endorsed by leading industry standards such as ASTM and ACI. These organizations have established specifications that assure quality control and compliance when utilizing these materials, providing confidence and security to engineers and builders globally. To fully reap the benefits of silica fume and fly ash, concrete producers and construction professionals must consider key factors such as particle size distribution, replacement levels, and the compatibility with other concrete mix components. Consulting with specialists in concrete mix designs can optimize these elements, ensuring that the resultant concrete not only meets the desired performance criteria but also adheres to sustainability goals. In conclusion, the integration of silica fume and fly ash into concrete mixes represents a quintessential advancement toward greener and more durable construction practices. These materials, backed by solid scientific research and industry validation, offer a dual advantage of enhancing the concrete's physical properties while supporting environmental sustainability initiatives. As the construction landscape continues to evolve, these SCMs stand as cornerstone resources in building a more resilient and eco-friendly future.

Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025