6 月 . 16, 2024 04:07

Back to list

Silica fume availability is crucial for the project.

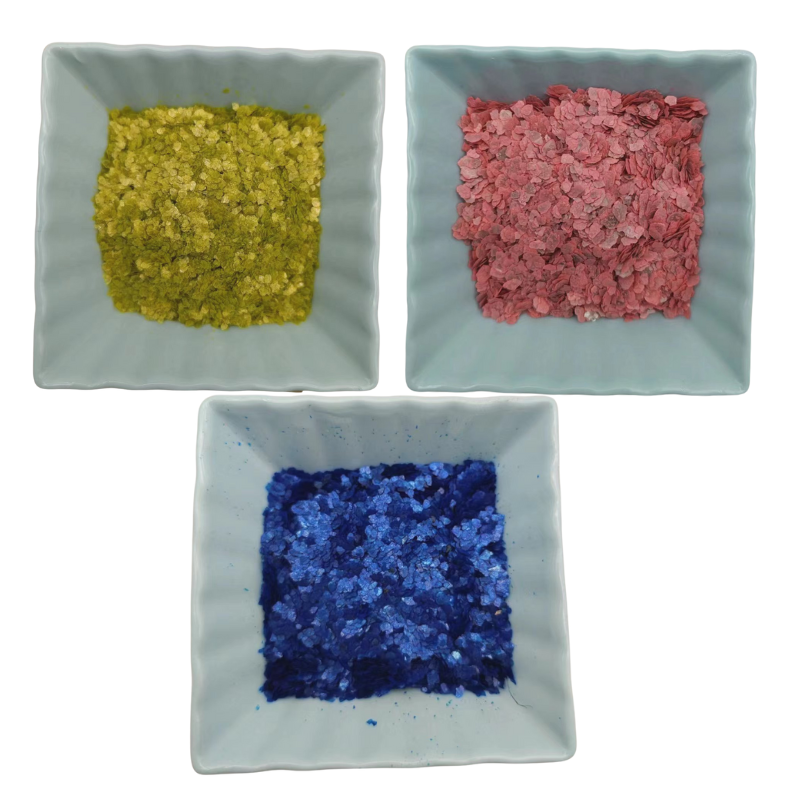

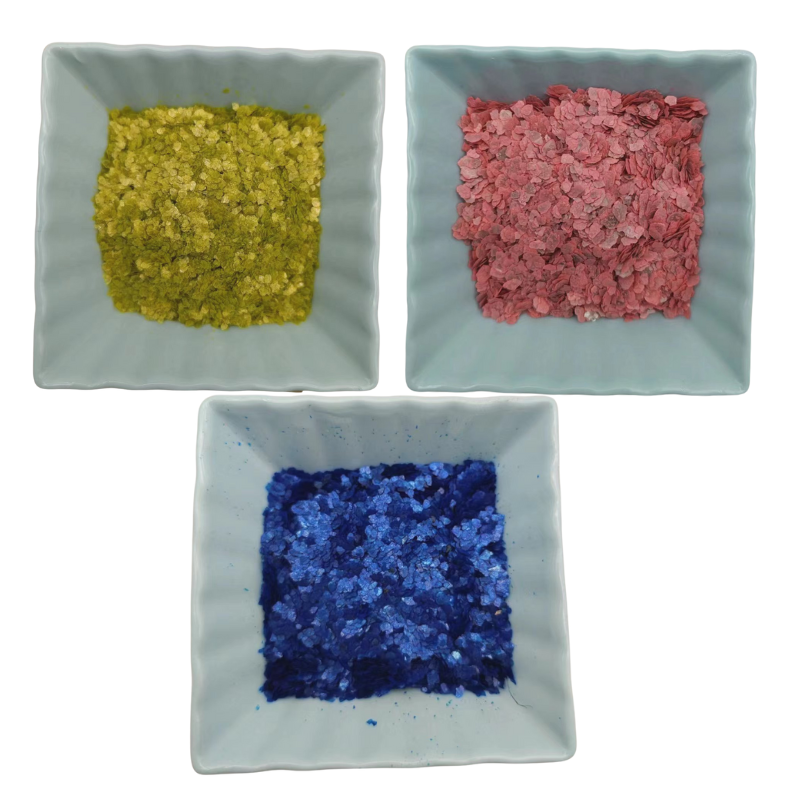

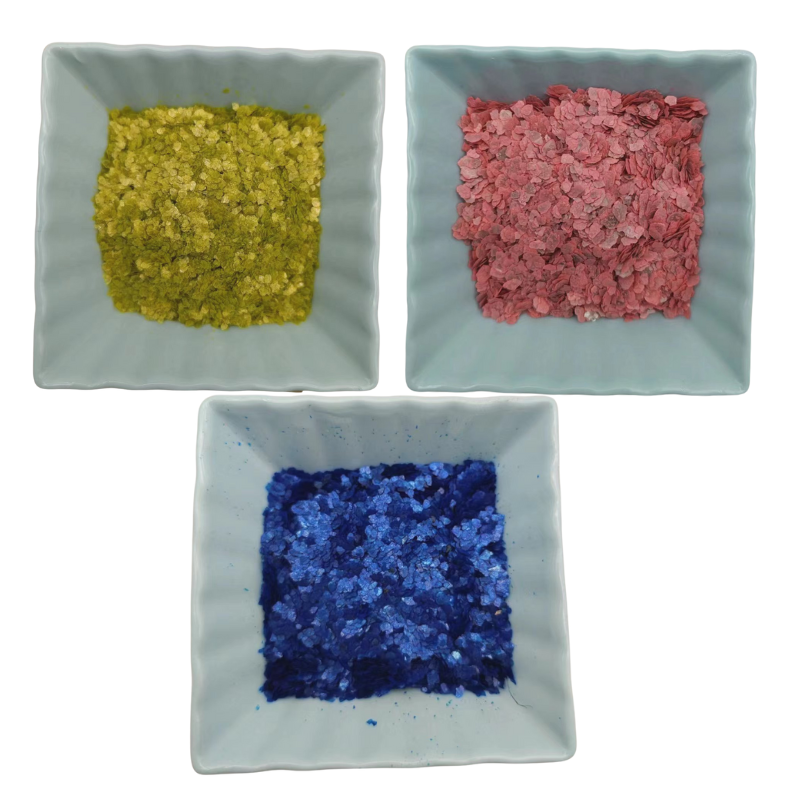

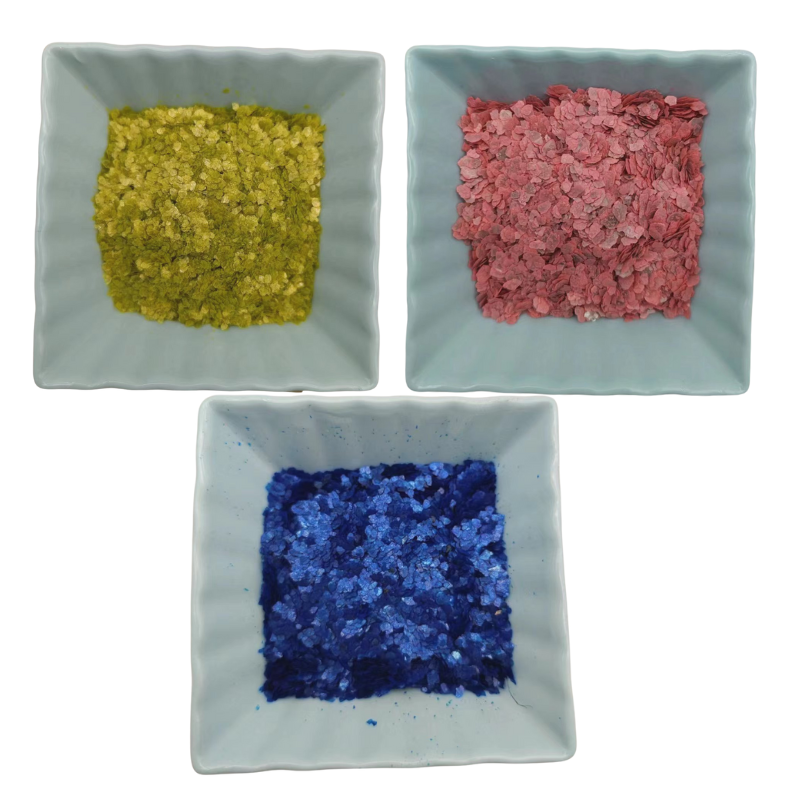

Silica fume, also known as microsilica or condensed silica fume, is a by-product of the production of silicon metal or ferrosilicon alloys. It is a very fine powder consisting of spherical particles of amorphous silica, which is an essential component in the manufacture of high-performance concrete. The unique properties of silica fume make it an invaluable material in various construction and industrial applications.

The availability of silica fume is crucial for the advancement of construction projects that demand high strength, durability, and reduced permeability. Silica fume is highly effective in enhancing the properties of concrete due to its extremely high surface area and reactivity. When added to concrete mixes, it reacts with calcium hydroxide, one of the by-products of cement hydration, to form additional calcium silicate hydrate, which improves both the strength and impermeability of the concrete. This reaction also reduces the amount of portlandite, which can lead to a weaker matrix and increased vulnerability to chemical attacks.

Availability issues can arise from various factors such as limitations in the production capacity of silicon metal or ferrosilicon alloys, logistical challenges in transportation, or regional market dynamics. For instance, if the primary industries producing these alloys face downtime, it directly impacts the supply chain of silica fume. Moreover, because silica fume is so lightweight and fine, it requires special handling to prevent health hazards associated with its inhalation during transportation and storage Moreover, because silica fume is so lightweight and fine, it requires special handling to prevent health hazards associated with its inhalation during transportation and storage Moreover, because silica fume is so lightweight and fine, it requires special handling to prevent health hazards associated with its inhalation during transportation and storage Moreover, because silica fume is so lightweight and fine, it requires special handling to prevent health hazards associated with its inhalation during transportation and storage

Moreover, because silica fume is so lightweight and fine, it requires special handling to prevent health hazards associated with its inhalation during transportation and storage Moreover, because silica fume is so lightweight and fine, it requires special handling to prevent health hazards associated with its inhalation during transportation and storage silica fume availability.

Environmental concerns also play a role in the availability of silica fume. As a by-product, recycling and reusing silica fume can help mitigate environmental pollution and reduce waste. However, the collection process must be efficient and economically viable to ensure consistent availability. In some regions, there may be limited awareness about the benefits of using silica fume, leading to underutilization and potential scarcity in areas where demand could be much higher.

In conclusion, the availability of silica fume is a multifaceted issue influenced by production capabilities, logistical considerations, environmental policies, and market awareness. Ensuring a steady supply of this crucial material is vital for maintaining the quality and progress of construction projects that rely on high-performance concrete. Therefore, stakeholders involved in the production and distribution of silica fume must work collaboratively to address any challenges that could affect its availability, thereby supporting continued innovation and sustainable development in the construction industry.

silica fume availability.

Environmental concerns also play a role in the availability of silica fume. As a by-product, recycling and reusing silica fume can help mitigate environmental pollution and reduce waste. However, the collection process must be efficient and economically viable to ensure consistent availability. In some regions, there may be limited awareness about the benefits of using silica fume, leading to underutilization and potential scarcity in areas where demand could be much higher.

In conclusion, the availability of silica fume is a multifaceted issue influenced by production capabilities, logistical considerations, environmental policies, and market awareness. Ensuring a steady supply of this crucial material is vital for maintaining the quality and progress of construction projects that rely on high-performance concrete. Therefore, stakeholders involved in the production and distribution of silica fume must work collaboratively to address any challenges that could affect its availability, thereby supporting continued innovation and sustainable development in the construction industry.

Moreover, because silica fume is so lightweight and fine, it requires special handling to prevent health hazards associated with its inhalation during transportation and storage Moreover, because silica fume is so lightweight and fine, it requires special handling to prevent health hazards associated with its inhalation during transportation and storage

Moreover, because silica fume is so lightweight and fine, it requires special handling to prevent health hazards associated with its inhalation during transportation and storage Moreover, because silica fume is so lightweight and fine, it requires special handling to prevent health hazards associated with its inhalation during transportation and storage silica fume availability.

Environmental concerns also play a role in the availability of silica fume. As a by-product, recycling and reusing silica fume can help mitigate environmental pollution and reduce waste. However, the collection process must be efficient and economically viable to ensure consistent availability. In some regions, there may be limited awareness about the benefits of using silica fume, leading to underutilization and potential scarcity in areas where demand could be much higher.

In conclusion, the availability of silica fume is a multifaceted issue influenced by production capabilities, logistical considerations, environmental policies, and market awareness. Ensuring a steady supply of this crucial material is vital for maintaining the quality and progress of construction projects that rely on high-performance concrete. Therefore, stakeholders involved in the production and distribution of silica fume must work collaboratively to address any challenges that could affect its availability, thereby supporting continued innovation and sustainable development in the construction industry.

silica fume availability.

Environmental concerns also play a role in the availability of silica fume. As a by-product, recycling and reusing silica fume can help mitigate environmental pollution and reduce waste. However, the collection process must be efficient and economically viable to ensure consistent availability. In some regions, there may be limited awareness about the benefits of using silica fume, leading to underutilization and potential scarcity in areas where demand could be much higher.

In conclusion, the availability of silica fume is a multifaceted issue influenced by production capabilities, logistical considerations, environmental policies, and market awareness. Ensuring a steady supply of this crucial material is vital for maintaining the quality and progress of construction projects that rely on high-performance concrete. Therefore, stakeholders involved in the production and distribution of silica fume must work collaboratively to address any challenges that could affect its availability, thereby supporting continued innovation and sustainable development in the construction industry. Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025