6 月 . 16, 2024 04:09

Back to list

Producing OEM concrete enhanced with perlite.

The Innovation of OEM Concrete with Perlite Factory

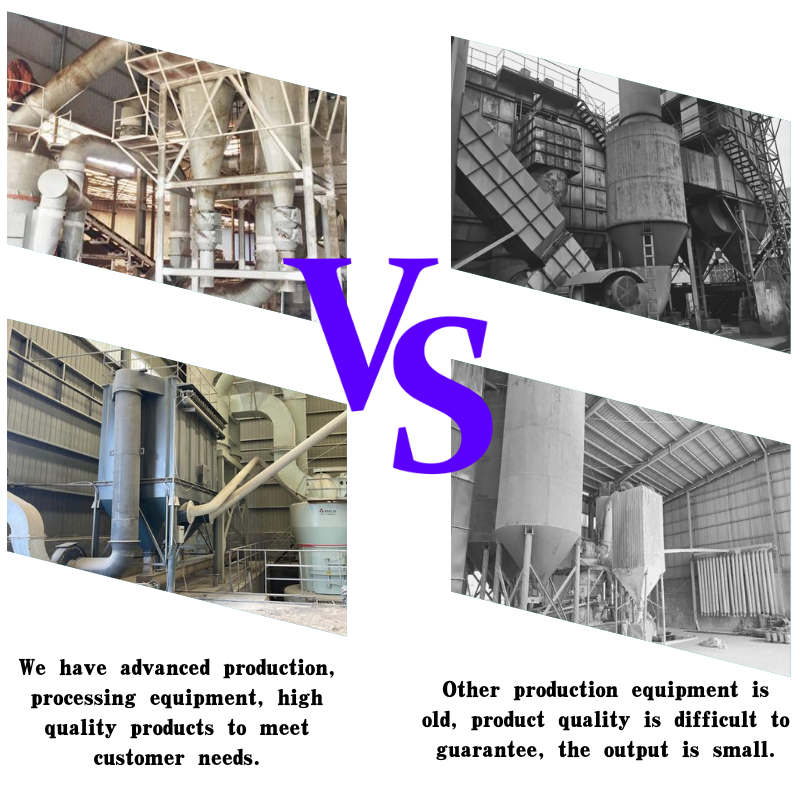

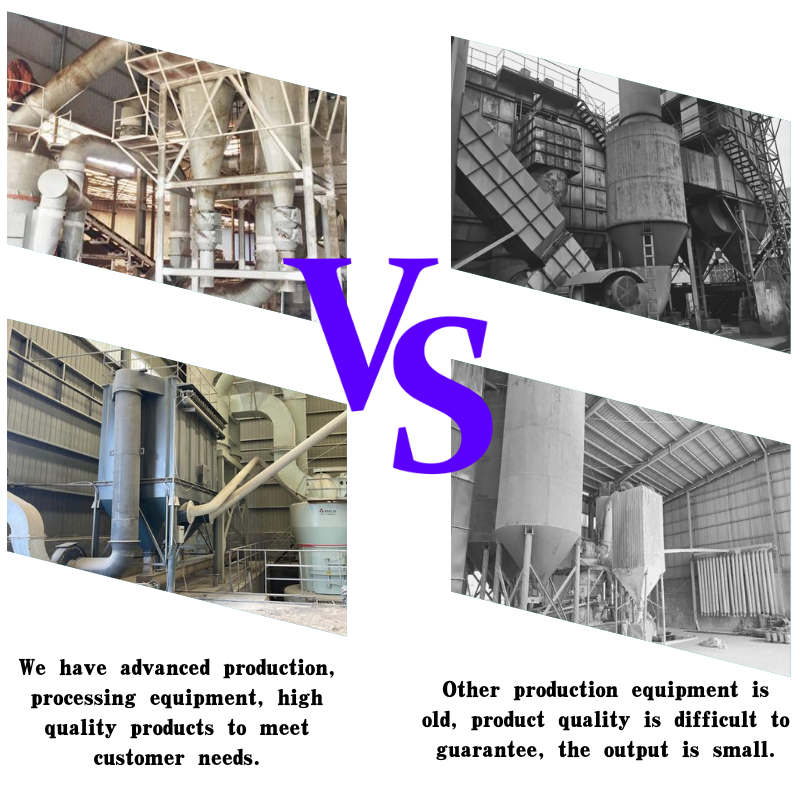

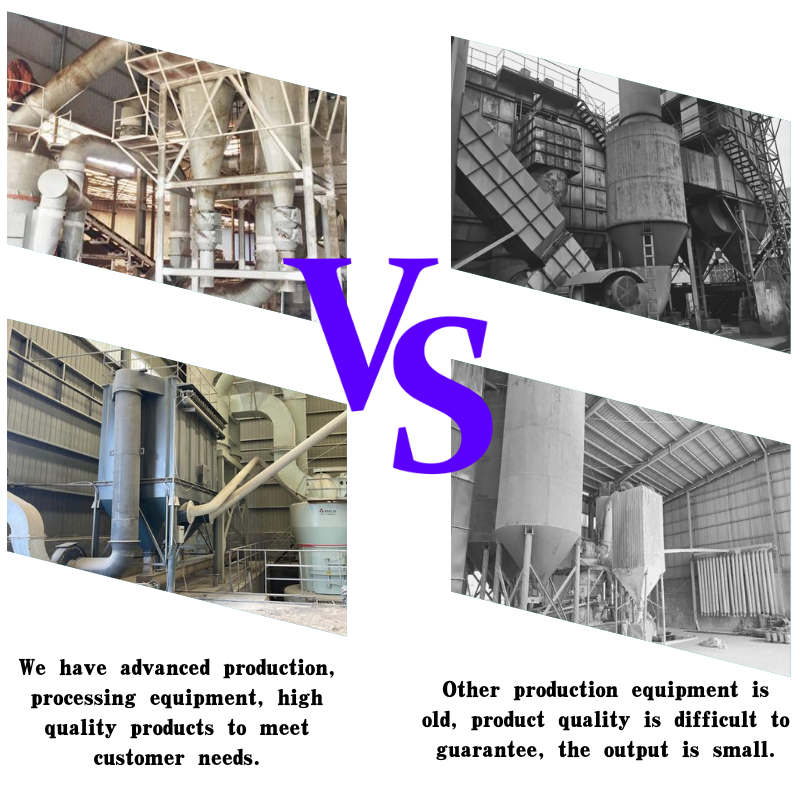

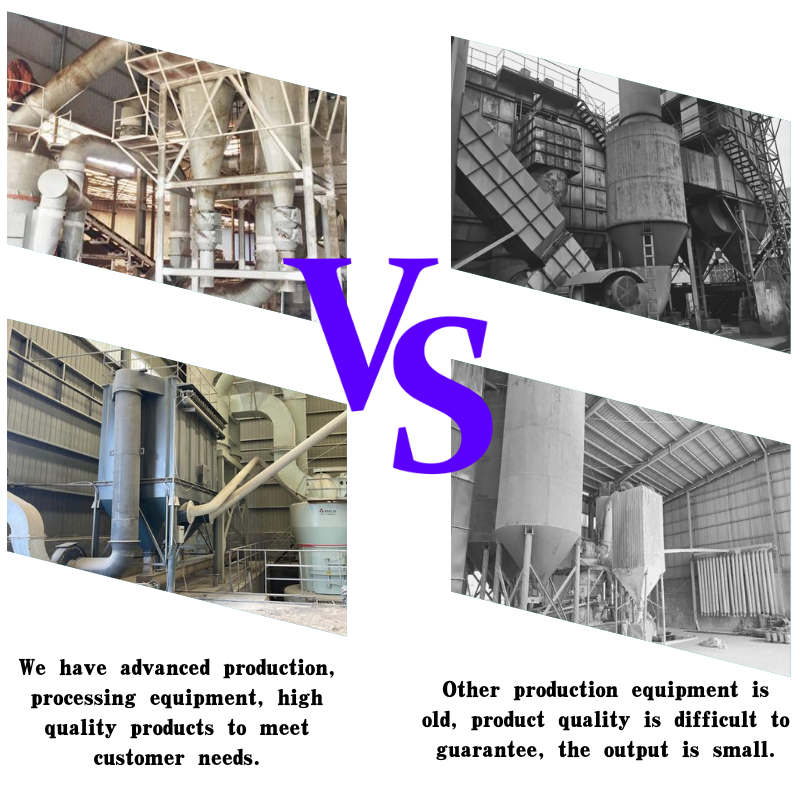

The integration of perlite into Original Equipment Manufacturer (OEM) concrete production has revolutionized the construction industry, offering enhanced performance and sustainability. This innovative approach by an OEM concrete with perlite factory not only improves the quality of the final product but also significantly reduces environmental impacts.

Perlite, a naturally occurring volcanic rock, is expanded under heat to create a lightweight, porous material that is ideal for concrete mixtures. When integrated into the OEM process, it provides several advantages over traditional concrete manufacturing methods. One of the primary benefits is its ability to reduce the density of concrete, making it easier to handle and transport while maintaining strength and durability. This lighter weight also allows for easier application in various construction projects, from high-rise buildings to infrastructure developments.

Another significant advantage of using perlite in OEM concrete production is its thermal insulation properties. The tiny air pockets within the perlite particles provide excellent resistance to heat transfer, making the concrete more energy-efficient in both warm and cold climates. This feature is particularly beneficial in the construction of buildings that require consistent internal temperatures, such as commercial spaces and residential homes, leading to reduced energy consumption and lower utility costs over time This feature is particularly beneficial in the construction of buildings that require consistent internal temperatures, such as commercial spaces and residential homes, leading to reduced energy consumption and lower utility costs over time This feature is particularly beneficial in the construction of buildings that require consistent internal temperatures, such as commercial spaces and residential homes, leading to reduced energy consumption and lower utility costs over time This feature is particularly beneficial in the construction of buildings that require consistent internal temperatures, such as commercial spaces and residential homes, leading to reduced energy consumption and lower utility costs over time

This feature is particularly beneficial in the construction of buildings that require consistent internal temperatures, such as commercial spaces and residential homes, leading to reduced energy consumption and lower utility costs over time This feature is particularly beneficial in the construction of buildings that require consistent internal temperatures, such as commercial spaces and residential homes, leading to reduced energy consumption and lower utility costs over time oem concrete with perlite factory.

The OEM concrete with perlite factory also focuses on sustainable practices. Perlite is a renewable resource, and its use in concrete helps to reduce the demand for other non-renewable materials. Furthermore, the addition of perlite can extend the lifespan of concrete structures due to its resistance to moisture penetration and freeze-thaw cycles, thereby decreasing maintenance costs and the need for frequent repairs or replacements.

In conclusion, the innovation of an OEM concrete with perlite factory marks a significant step forward for the construction industry. By incorporating perlite into their manufacturing processes, these factories not only produce higher-quality, more efficient concrete but also promote environmental stewardship. As we continue to seek solutions that balance economic growth with ecological responsibility, the success of this model is likely to inspire further advances in sustainable construction practices worldwide.

oem concrete with perlite factory.

The OEM concrete with perlite factory also focuses on sustainable practices. Perlite is a renewable resource, and its use in concrete helps to reduce the demand for other non-renewable materials. Furthermore, the addition of perlite can extend the lifespan of concrete structures due to its resistance to moisture penetration and freeze-thaw cycles, thereby decreasing maintenance costs and the need for frequent repairs or replacements.

In conclusion, the innovation of an OEM concrete with perlite factory marks a significant step forward for the construction industry. By incorporating perlite into their manufacturing processes, these factories not only produce higher-quality, more efficient concrete but also promote environmental stewardship. As we continue to seek solutions that balance economic growth with ecological responsibility, the success of this model is likely to inspire further advances in sustainable construction practices worldwide.

This feature is particularly beneficial in the construction of buildings that require consistent internal temperatures, such as commercial spaces and residential homes, leading to reduced energy consumption and lower utility costs over time This feature is particularly beneficial in the construction of buildings that require consistent internal temperatures, such as commercial spaces and residential homes, leading to reduced energy consumption and lower utility costs over time

This feature is particularly beneficial in the construction of buildings that require consistent internal temperatures, such as commercial spaces and residential homes, leading to reduced energy consumption and lower utility costs over time This feature is particularly beneficial in the construction of buildings that require consistent internal temperatures, such as commercial spaces and residential homes, leading to reduced energy consumption and lower utility costs over time oem concrete with perlite factory.

The OEM concrete with perlite factory also focuses on sustainable practices. Perlite is a renewable resource, and its use in concrete helps to reduce the demand for other non-renewable materials. Furthermore, the addition of perlite can extend the lifespan of concrete structures due to its resistance to moisture penetration and freeze-thaw cycles, thereby decreasing maintenance costs and the need for frequent repairs or replacements.

In conclusion, the innovation of an OEM concrete with perlite factory marks a significant step forward for the construction industry. By incorporating perlite into their manufacturing processes, these factories not only produce higher-quality, more efficient concrete but also promote environmental stewardship. As we continue to seek solutions that balance economic growth with ecological responsibility, the success of this model is likely to inspire further advances in sustainable construction practices worldwide.

oem concrete with perlite factory.

The OEM concrete with perlite factory also focuses on sustainable practices. Perlite is a renewable resource, and its use in concrete helps to reduce the demand for other non-renewable materials. Furthermore, the addition of perlite can extend the lifespan of concrete structures due to its resistance to moisture penetration and freeze-thaw cycles, thereby decreasing maintenance costs and the need for frequent repairs or replacements.

In conclusion, the innovation of an OEM concrete with perlite factory marks a significant step forward for the construction industry. By incorporating perlite into their manufacturing processes, these factories not only produce higher-quality, more efficient concrete but also promote environmental stewardship. As we continue to seek solutions that balance economic growth with ecological responsibility, the success of this model is likely to inspire further advances in sustainable construction practices worldwide. Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025