Perlite Stone Production Facility for High-Quality Lightweight Construction Materials

The Role and Importance of Perlite Stone Factories

Perlite, a volcanic glass that expands when heated, has become an increasingly vital material in various industries, including construction, horticulture, and food processing. As demand for this versatile substance grows, perlite stone factories play a crucial role in meeting both local and global needs. This article explores the operations, benefits, and environmental considerations associated with perlite stone factories.

Understanding Perlite

Perlite is characterized by its lightweight, porous nature, making it an ideal component for a wide range of applications. When heated to high temperatures (around 1,600°F), perlite expands to many times its original size, forming a lightweight, white, and glass-like material. This unique property allows perlite to provide excellent insulation, drainage, and aeration, making it invaluable in sectors such as construction and horticulture.

The Operations of Perlite Stone Factories

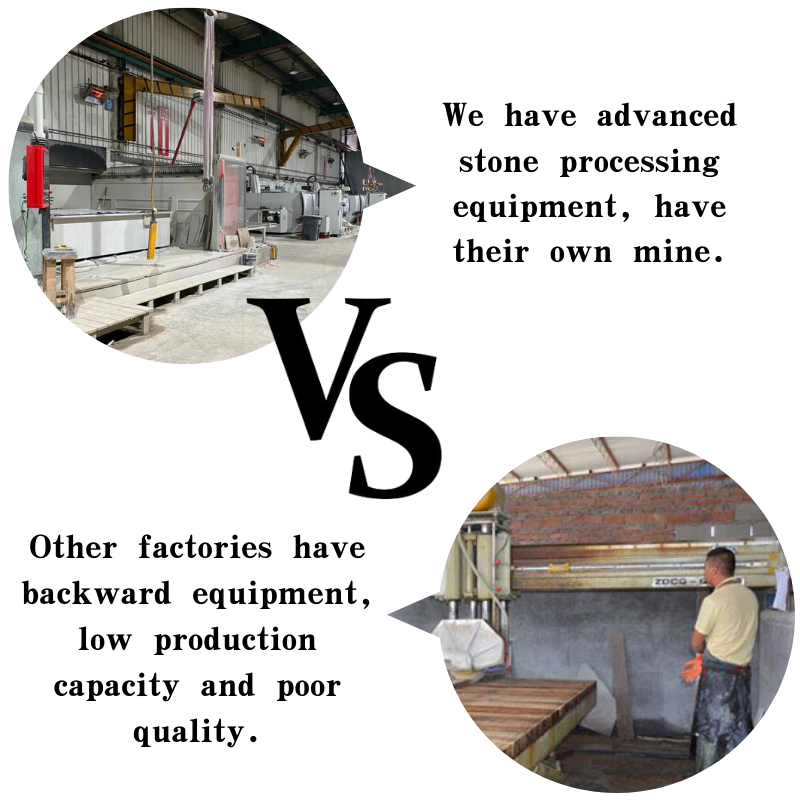

Perlite stone factories are equipped with advanced machinery designed to extract, crush, and expand perlite ore. The production process typically involves several key steps

1. Mining Perlite is mined from deposits found in volcanic regions. This extraction process requires careful planning and implementation to minimize environmental impact. 2. Crushing Once mined, the perlite ore is crushed into smaller pieces to prepare it for expansion. The size of the crushed material can be tailored to different market needs.

3. Expansion The crushed perlite is then heated in a furnace where it expands, creating the lightweight material that is sought after by various industries.

4. Sifting and Packaging After expansion, the perlite is sieved to achieve different particle sizes, depending on its intended use, before being packaged for distribution.

Applications of Perlite

perlite stone factory

Perlite's unique properties lend themselves to a wide array of applications

- Construction In the construction industry, perlite is used as an insulating material, lightweight aggregate in concrete, and as a filler in various products. Its insulation capabilities help reduce energy costs and improve building efficiency.

- Horticulture For gardeners and landscape architects, perlite is often used in potting mixes to improve soil aeration and drainage. Its lightweight nature reduces the overall weight of containers, making it easier to handle.

- Food Processing Perlite is also utilized in the food industry for filtration and as a stabilizing agent in various food products, thanks to its natural and non-toxic composition.

Environmental Considerations

While perlite stone factories contribute significantly to industrial supply chains, it’s vital to manage their environmental impact. Sustainable mining practices must be implemented to prevent habitat destruction and soil degradation. Moreover, waste management strategies should be developed to recycle or reuse byproducts from the production process.

Additionally, increasing energy efficiency during the expansion process can help reduce the carbon footprint of these operations. By adopting cleaner technologies and renewable energy sources, perlite stone factories can operate in a more eco-friendly manner.

Conclusion

Perlite stone factories are essential in producing a material that plays a critical role in various industries. Their operations—ranging from mining to processing—must pay close attention to environmental sustainability. As demand continues to rise, these factories will remain integral to providing innovative solutions across multiple sectors, ensuring that the remarkable properties of perlite enhance both products and practices in the modern world.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025