Bulk Zeolite Rocks from OEM Factories for Various Applications and Industries

The Role of OEM Zeolite Rocks in Modern Mining Industries

In recent years, the demand for zeolite rocks has increased substantially across various industries, ranging from agriculture to environmental remediation. Original Equipment Manufacturer (OEM) zeolite rocks have gained popularity due to their unique properties and versatile applications. This article explores the significance of OEM zeolite rocks, their production in bulk factories, and their impact on different sectors.

Understanding Zeolite Rocks

Zeolites are naturally occurring or synthetic minerals composed of hydrated aluminosilicates. They are characterized by their porous structure, which allows them to adsorb and exchange cations. This unique property makes zeolites valuable in numerous applications, such as water purification, soil enhancement, and as catalysts in chemical processes.

OEM zeolite rocks refer to zeolites produced by manufacturers that provide customized products tailored to meet the specific requirements of their clients. These bulk factories specialize in large-scale production, ensuring consistent quality and availability of zeolite products.

Production in Bulk Factories

Bulk production of OEM zeolite rocks involves intricate processes that begin with the extraction of raw materials from natural deposits. Once obtained, these materials undergo thorough processing, which may include crushing, grinding, and thermal treatment to achieve the desired properties. Advanced technologies and machinery are deployed in these factories to ensure efficiency and precision, allowing for the mass production of zeolite rocks.

The factories also emphasize quality control, implementing strict standards to ensure the end product meets industrial requirements. Regular testing and analysis are performed on the zeolite rocks to evaluate their composition, porosity, and ion-exchange capacities.

oem zeolite rocks bulk factories

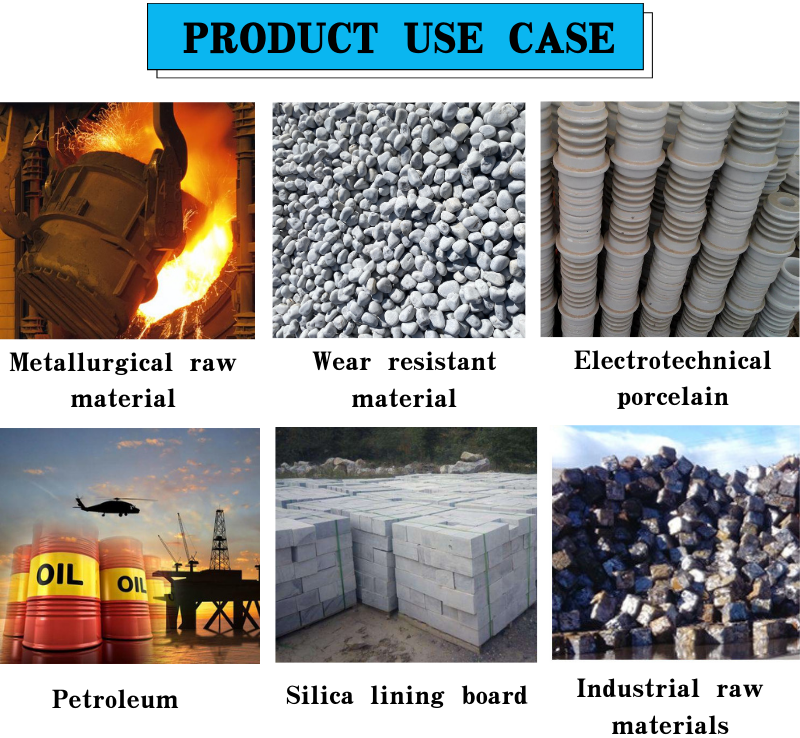

Applications of OEM Zeolite Rocks

1. Agriculture One of the most significant uses of OEM zeolite rocks is in agriculture. Farmers use zeolite as a soil amendment to enhance water retention, improve nutrient exchange, and promote healthy plant growth. The ability of zeolites to adsorb excess moisture and nutrients reduces the need for chemical fertilizers, promoting sustainable farming practices.

2. Water Treatment In environmental applications, OEM zeolite rocks are adept at purifying water. Their ion-exchange properties allow them to remove harmful contaminants and heavy metals from wastewater, making them an eco-friendly solution for water treatment facilities.

3. Industrial Processes Zeolites serve as catalysts in various industrial processes due to their ability to promote chemical reactions without being consumed. OEM zeolite rocks are used in petrochemical industries, detergent manufacturing, and as desiccants in packaging, demonstrating their versatility in diverse applications.

4. Animal Feed Another emerging market for OEM zeolite rocks is in the livestock industry. Zeolites are used as feed additives to enhance nutrient absorption in animals, which not only improves their health but also promotes better feed efficiency and reduces waste.

Conclusion

The production of OEM zeolite rocks in bulk factories is a testament to the growing recognition of these minerals in various industries. Their unique properties offer valuable solutions for problems related to agriculture, water purification, and industrial processes. As the demand for sustainable and eco-friendly products continues to rise, the role of zeolites will undoubtedly expand, making them integral to future innovations in multiple sectors. With advancements in production techniques and an increasing understanding of their benefits, OEM zeolite rocks are poised to play a crucial role in addressing some of the pressing challenges faced by modern society.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025