OEM Silica Fume Suppliers for High-Quality Brick Manufacturing Solutions

The Role of OEM Silica Fume in Brick Manufacturing

In the world of construction materials, the quest for durability, strength, and sustainability has always been paramount. Among the various materials that play a significant role in enhancing the performance of bricks, silica fume stands out due to its unique properties. Silica fume, a byproduct of silicon metal or ferrosilicon alloys, is a fine particulate material that can significantly improve the quality of bricks. In recent years, Original Equipment Manufacturers (OEMs) have increasingly utilized silica fume in brick manufacturing, creating opportunities for innovation and efficiency in the industry.

Silica fume is composed of over 90% silicon dioxide, which contributes to its pozzolanic characteristics. When incorporated into brick formulations, silica fume enhances the microstructure by filling the voids between larger particles, thus increasing the density and strength of the end product. This not only leads to stronger bricks but also improves their resistance to water infiltration and chemical attacks, which are critical factors in the longevity of masonry structures.

The Role of OEM Silica Fume in Brick Manufacturing

Beyond enhancing physical properties, silica fume contributes to sustainability in brick manufacturing. The incorporation of silica fume reduces the amount of cement required in the mix, leading to a lower carbon footprint. Cement production is a significant source of CO2 emissions; therefore, utilizing silica fume not only improves brick quality but also addresses environmental concerns. As the construction industry moves towards greener practices, the demand for sustainable materials, such as those containing silica fume, is expected to rise.

oem silica fume in brick manufacturers

Moreover, the versatility of silica fume allows manufacturers to innovate and tailor their products to meet specific requirements. Different types and grades of silica fume can be sourced based on the intended application of the bricks, whether it's for residential buildings, commercial structures, or infrastructure projects. OEMs have the opportunity to collaborate with silica fume producers to create customized solutions, resulting in high-performance bricks that cater to the diverse needs of the market.

As the construction industry continues to evolve, the role of OEM silica fume in brick manufacturing is likely to expand further. With ongoing research and development, manufacturers are discovering new ways to incorporate silica fume into their production processes. This includes exploring the combination of silica fume with other supplementary cementitious materials (SCMs) to enhance the overall performance of bricks.

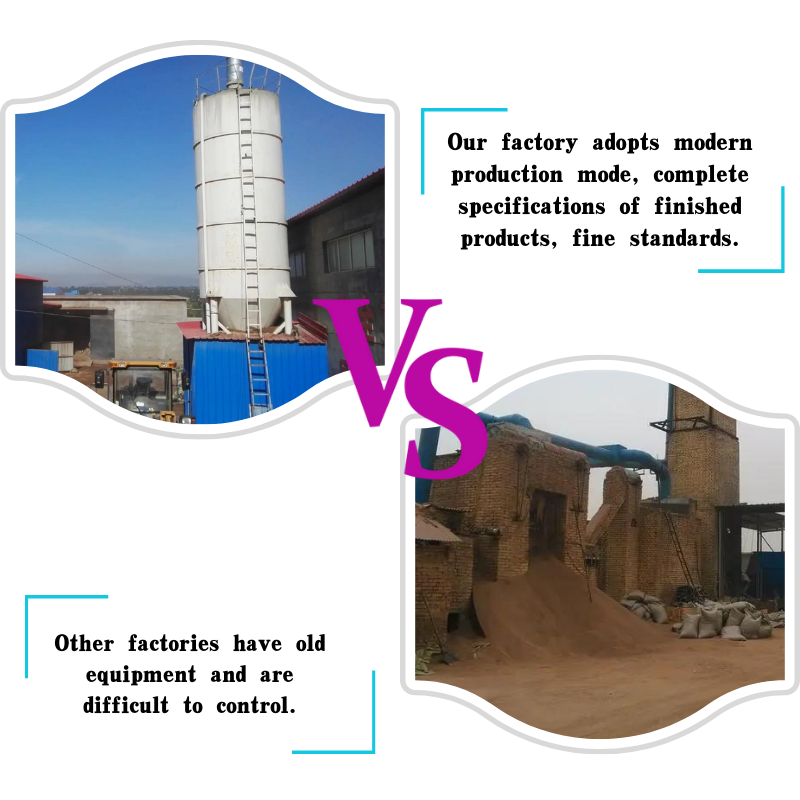

Additionally, the ongoing advancements in technology and production methods are enabling manufacturers to achieve a more consistent quality of silica fume, making it easier to integrate it into existing production lines. This consistency is key in ensuring that the benefits of silica fume are fully realized in the brick-making process.

In conclusion, the integration of OEM silica fume in brick manufacturing represents a significant advancement in the quest for stronger, more durable, and sustainable building materials. Its numerous benefits, such as increased strength, reduced permeability, and a lower environmental impact, make it a valuable addition to modern brick production. As builders and manufacturers continue to prioritize quality and sustainability, silica fume will likely play a critical role in shaping the future of the construction industry.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025