oem sheet mica

Understanding OEM Sheet Mica Properties, Uses, and Benefits

Mica, a naturally occurring mineral, has garnered significant attention in various industries due to its unique physical and chemical properties. Among the different forms of mica available in the market, OEM sheet mica stands out for its versatility and functionality. The term OEM refers to Original Equipment Manufacturer, indicating that these mica sheets are manufactured to meet the specific standards and requirements of various industrial applications. This article explores the properties, uses, and benefits of OEM sheet mica.

Properties of OEM Sheet Mica

OEM sheet mica possesses several distinctive properties that make it a valuable material. Firstly, it has excellent thermal insulation capabilities, allowing it to withstand high temperatures without degrading or losing its integrity. This property is particularly useful in applications where heat resistance is crucial, such as in electrical insulation and heating elements.

Additionally, OEM sheet mica is characterized by its dielectric strength, which makes it an ideal material for electrical and electronic applications. The high dielectric strength ensures that it can effectively isolate electrical components, preventing short circuits and other electrical failures. Furthermore, sheet mica is chemically inert, meaning it does not react with most chemicals, making it suitable for use in various corrosive environments.

Applications of OEM Sheet Mica

The applications of OEM sheet mica are vast and varied, encompassing several industries. One of the primary uses is in the electrical and electronics industry, where it serves as a key insulating material for capacitors, transformers, and circuit boards. Its ability to handle high voltages and temperatures makes it an invaluable component in these applications.

oem sheet mica

In addition to electrical applications, OEM sheet mica is widely used in the automotive industry. It is utilized in components such as gaskets, seals, and heat shields, where resistance to heat and chemicals is paramount. The aerospace sector also benefits from sheet mica in the manufacture of lightweight, heat-resistant components.

Moreover, OEM sheet mica is an essential material in the cosmetic industry. Its reflective properties provide a shimmering effect in makeup products, making it a popular choice for manufacturers of foundations, eyeshadows, and other cosmetic items.

Benefits of Using OEM Sheet Mica

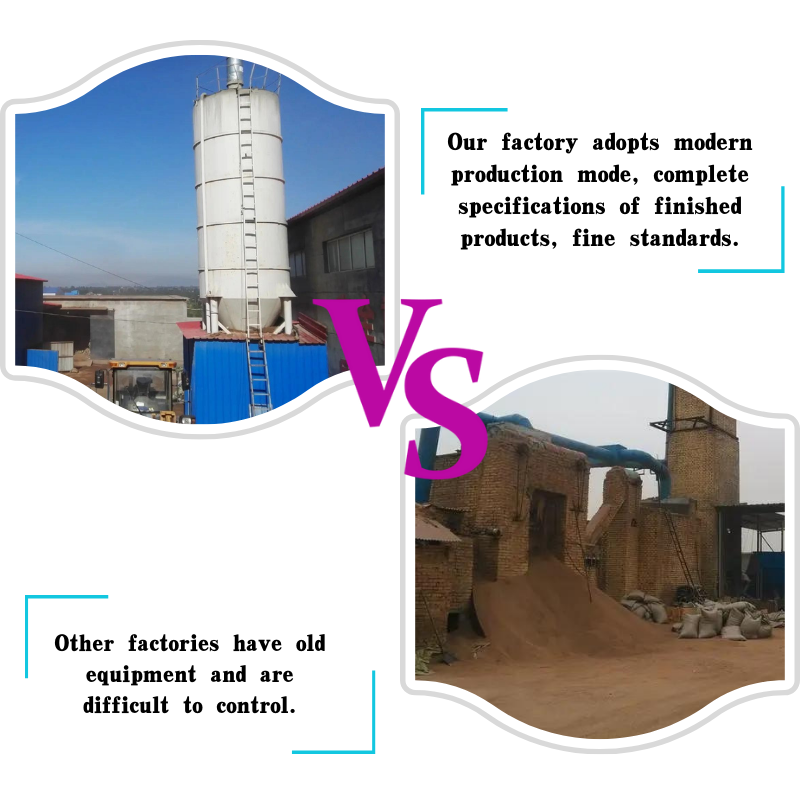

Choosing OEM sheet mica offers several advantages for manufacturers and industries alike. The customization aspect of OEM production means that manufacturers can request mica sheets tailored to specific sizes, thicknesses, and properties, ensuring optimal performance for their unique applications. This adaptability can streamline production processes and enhance product quality.

Another key benefit is the longevity and durability of OEM sheet mica. Its resistance to heat, moisture, and chemical degradation means that products utilizing this material often have extended lifespans and improved reliability. This durability can translate to cost savings for companies, as it reduces the frequency of replacements and maintenance.

In conclusion, OEM sheet mica is a remarkable material with a diverse range of applications across various industries. Its unique properties, coupled with the customization options available through OEM manufacturing, make it an essential choice for companies looking to enhance their products’ performance and reliability. As technology continues to advance, the demand for high-quality mica materials will likely increase, further solidifying OEM sheet mica's role in industrial applications.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025