OEM Rutile-Type Titanium Dioxide for High-Performance Applications and Coatings

Understanding OEM Rutile Type Titanium Dioxide

Titanium dioxide (TiO2) is one of the most widely used white pigments in the world. Among its various forms, rutile type titanium dioxide stands out due to its superior properties, making it a critical component in numerous applications. When we refer to OEM (Original Equipment Manufacturer) rutile type titanium dioxide, we enter a realm where quality, consistency, and customization meet the demands of various industries.

Rutile titanium dioxide is renowned for its excellent opacity, high refractive index, and exceptional UV resistance. These attributes make it particularly valuable in sectors such as paints, coatings, plastics, paper, and even cosmetics. The rutile form of titanium dioxide delivers superior coverage compared to its alternative, the anatase form, which tends to be less stable and has inferior properties for most industrial applications.

OEM rutile type titanium dioxide producers play a crucial role in the supply chain by offering tailored solutions that meet specific customer requirements. The demand for customized characteristics—such as particle size, surface treatment, and dispersion properties—has led manufacturers to innovate continuously. By providing bespoke formulations, OEMs help industries achieve optimal performance in their products, whether it be enhancing the durability of paint or improving the aesthetics of consumer goods.

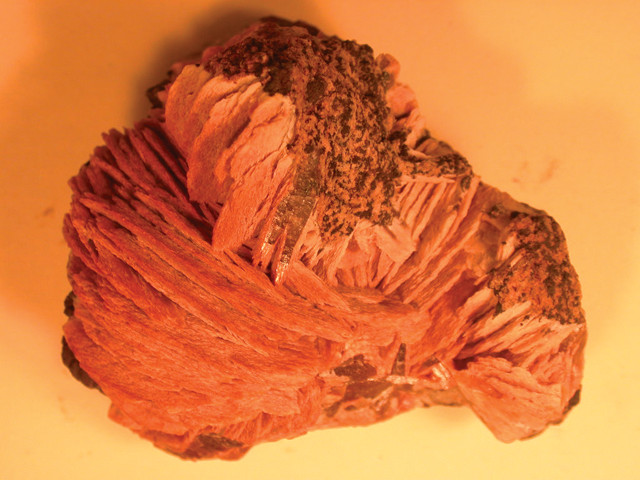

oem rutile type titanium dioxide

The processing of rutile titanium dioxide involves several steps, including the sulfate and chloride methods. Both methods aim to produce a high-purity product, but they differ in their environmental impact and cost-effectiveness. The chloride process, for example, tends to be more efficient and produces less waste, making it a preferable option among manufacturers focused on sustainability.

As industries increasingly prioritize sustainability, OEM rutile type titanium dioxide producers are under pressure to adapt

. Many are investing in greener technologies and practices to minimize their carbon footprint. This shift not only aids in regulatory compliance but also aligns with consumers' growing preference for eco-friendly products.Moreover, the application of rutile titanium dioxide goes beyond traditional uses. In the realm of technology, it is being explored for its potential in photocatalysis and photovoltaic cells, showcasing the versatility and importance of this compound in emerging fields.

In conclusion, OEM rutile type titanium dioxide is an essential material that underpins numerous industries, characterized by its outstanding properties. The continuous evolution of manufacturing tailored solutions, alongside a commitment to sustainability, highlights the significance of this compound in today's market. As global demand grows, so too will the innovations that drive the future of rutile type titanium dioxide, ensuring its place at the forefront of materials science.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025