oem perlite plants manufacturer

The Role of OEM Perlite Plants Manufacturers in the Horticulture and Construction Industries

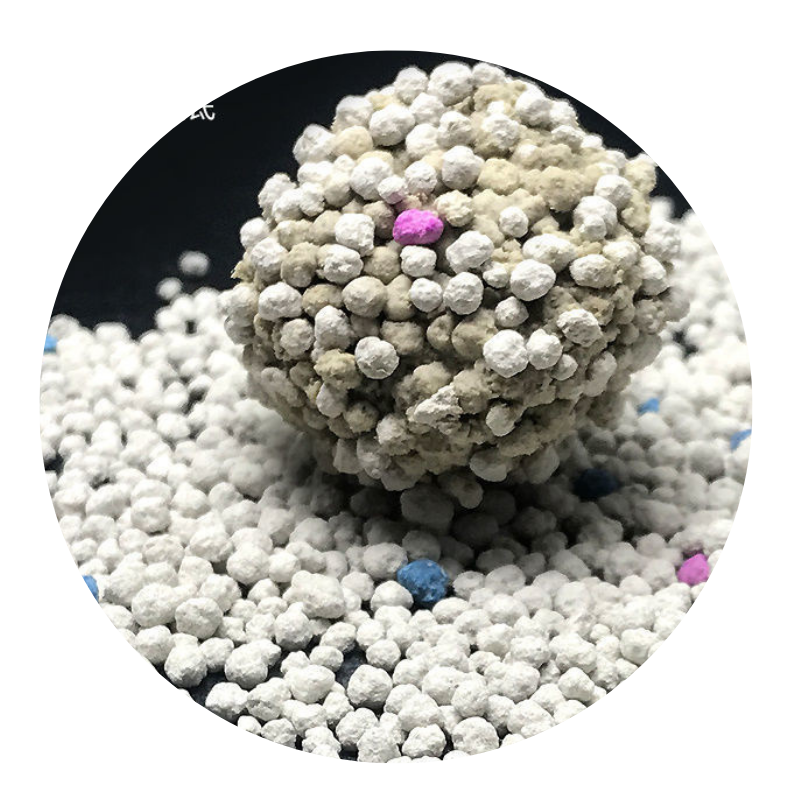

In the ever-evolving landscape of horticulture and construction, one material has consistently stood out for its versatility and effectiveness perlite. This naturally occurring volcanic glass, when heated and expanded, provides a lightweight, sterile substrate ideal for a variety of applications. The demand for high-quality perlite has driven the rise of Original Equipment Manufacturer (OEM) perlite plants, which specialize in producing perlite both for horticultural use and other industrial applications. In this article, we will explore the significance of these manufacturers, the production process, and the diverse uses of perlite in various industries.

Understanding OEM Perlite Plants

OEM perlite plants are specialized facilities that produce perlite products to meet specific customer specifications. They work closely with horticulturists, construction companies, and other industries to create customized perlite solutions tailored to their needs. These manufacturers focus on quality control and adhere to stringent standards, ensuring that the perlite they produce meets the required specifications for various applications.

By offering OEM services, these plants can provide a wide range of perlite grades that cater to different uses, including horticulture, insulation, and even as a lightweight aggregate in concrete. This flexibility and adaptability are crucial in meeting the diverse demands of the market, allowing customers to obtain perlite that is perfectly suited to their specific requirements.

The Production Process of Perlite

The production of perlite begins with the mining of raw perlite ore, which is then heated in furnaces to around 1,600 degrees Fahrenheit (870 degrees Celsius). This intense heat causes the moisture within the perlite to rapidly expand, creating a lightweight, porous material. Once cooled, the expanded perlite can be crushed and screened into various particle sizes, allowing manufacturers to produce perlite that is ideal for both horticultural and industrial applications.

Quality is paramount in the production process. OEM perlite plants often perform rigorous testing to ensure that the final product is free from impurities and meets the specific characteristics required by the end-user. This commitment to quality helps build trust and long-term relationships with clients who rely on perlite for their operations.

Horticultural Applications of Perlite

In the horticulture industry, perlite is widely recognized for its exceptional drainage and aeration properties. It is commonly mixed with potting soils to improve their texture and promote healthy root development. The lightweight nature of perlite also helps prevent soil compaction, ensuring that plant roots have adequate space to grow.

oem perlite plants manufacturer

Moreover, perlite is sterile, which means it does not harbor pests or diseases, making it an excellent choice for seed starting and cloning. Many professional growers and home gardening enthusiasts turn to OEM perlite plants for high-quality perlite that meets their specific horticultural needs. By customizing their products, these manufacturers ensure that growers have access to the best materials for their plants, ultimately leading to healthier and more vigorous growth.

Construction and Industrial Uses

Beyond horticulture, perlite is also used extensively in construction and industrial applications. Its lightweight and insulating properties make it an ideal component in lightweight concrete, which is used in a variety of structural applications. This reduces the overall weight of the building materials, lowering transportation costs and improving structural efficiency.

Perlite is also used in fireproofing materials, insulation, and as a filler in various manufacturing processes. The ability of perlite to withstand high temperatures and its impressive sound-dampening qualities make it a valuable addition to construction materials aimed at enhancing safety and comfort.

The Future of OEM Perlite Plants

As industries continue to evolve, the role of OEM perlite plants will likely expand. The growing emphasis on sustainability and eco-friendly practices in both horticulture and construction has created new opportunities for perlite use. Manufacturers are increasingly focusing on developing innovative products that align with these trends, such as organic gardening solutions and environmentally friendly construction materials.

Moreover, as global populations increase and urbanization continues, the demand for lightweight and effective building materials will grow. This positions OEM perlite plants as key players in creating sustainable solutions that can meet the challenges of modern construction and gardening.

Conclusion

In conclusion, OEM perlite plants manufacturers play a pivotal role in providing high-quality perlite for various industries, including horticulture and construction. Their ability to offer customized solutions ensures that clients receive the right materials for their specific needs while promoting healthy plant growth and improving construction methods. With a focus on quality and sustainability, these manufacturers are well-positioned to drive innovation and support the evolving demands of the market. As we advance, the significance of perlite and the manufacturers who produce it will only continue to grow, contributing to a more sustainable and efficient future.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025