OEM Natural Sea Sand Production Facility for Quality Supply and Custom Solutions

The Advantages of OEM Natural Sea Sand A New Era for Factories

In the ever-evolving landscape of industrial manufacturing, the emphasis on sustainability and environmental responsibility has become paramount. One innovative solution that has emerged is the use of OEM (Original Equipment Manufacturer) natural sea sand. This approach not only offers a viable alternative to traditional materials but also caters to a growing demand for ecologically friendly production processes.

The Advantages of OEM Natural Sea Sand A New Era for Factories

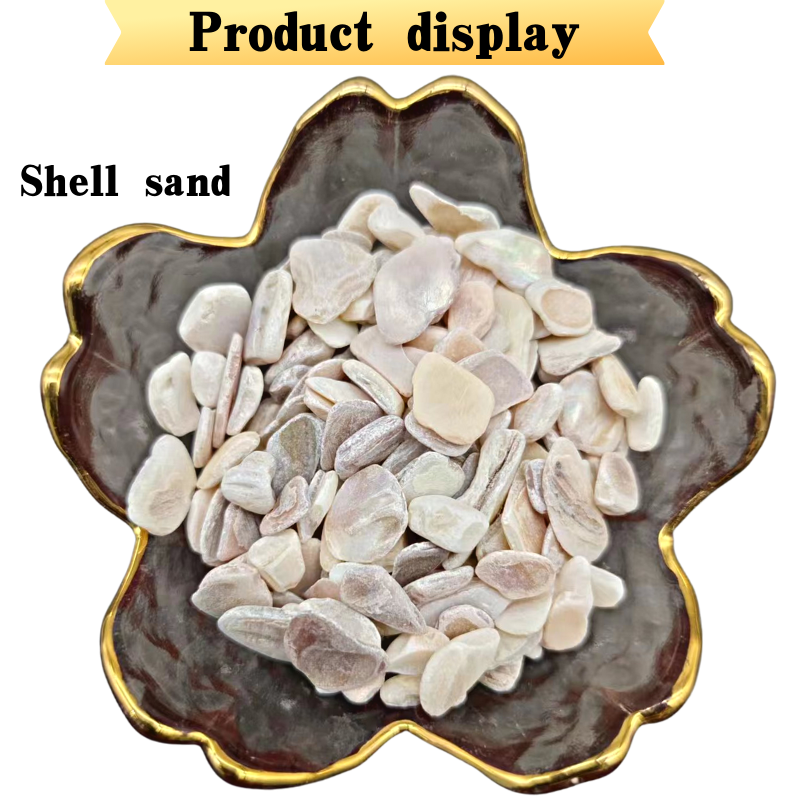

One of the key advantages of using OEM natural sea sand is its superior quality. Unlike artificial sand or manufactured aggregates, natural sea sand is free from impurities and harmful chemicals. Its fine granules are smooth and uniform, contributing to better binding properties in construction materials like concrete. This leads to enhanced strength and durability, which is critical for meeting building codes and safety standards.

oem natural sea sand factory

Furthermore, the use of natural sea sand can significantly lower production costs for factories. With increasing regulations around land-based sand mining, many manufacturers have turned to alternate sources for raw materials. By integrating OEM natural sea sand into their supply chain, factories can tap into a lesser-known resource that offers competitive pricing without compromising on quality. Additionally, as the demand for eco-friendly materials grows, businesses that adopt sustainable practices can position themselves favorably in the market, attracting environmentally-conscious consumers.

The environmental benefits of utilizing OEM natural sea sand cannot be overstated. Traditional sand mining can lead to significant ecological disruptions, including habitat destruction and increased erosion. In contrast, when sourced sustainably from the ocean, sea sand harvesting can be managed in a way that minimizes harm to marine ecosystems. Manufacturers adopting this practice not only contribute to marine conservation efforts but also set an industry standard that encourages other companies to follow suit.

Moreover, the versatility of natural sea sand extends beyond construction materials. It is also used in a variety of applications such as glass manufacturing, filtration systems, and landscaping. Its ability to function well in diverse environments makes it an efficient resource for OEM factories looking to innovate and diversify their product offerings.

In conclusion, the adoption of OEM natural sea sand represents a transformative step for factories aiming to enhance their sustainability and efficiency. Its high quality, cost-effectiveness, and minimal ecological impact make it an attractive choice for manufacturers in a wide array of industries. By leveraging this natural resource, factories can align with global sustainability goals while maintaining competitive advantages. As we move towards a greener future, the integration of OEM natural sea sand is not just an option but a necessity for responsible manufacturing.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025