OEM Mixed Glass Beads Manufacturers for Custom Solutions and High Quality Products

The Rise of OEM Mix Glass Beads Factories Innovation and Sustainability in Manufacturing

In recent years, the manufacturing industry has witnessed a significant transformation, particularly in the production of specialized materials such as glass beads. Among the various sectors involved in this transformation, OEM (Original Equipment Manufacturer) mix glass beads factories have gained considerable attention for their innovative approaches and commitment to sustainability. This article explores the growing trend of OEM mix glass beads factories, their impact on various industries, and their contribution to a greener future.

Understanding OEM Mix Glass Beads

OEM mix glass beads are small, spherical particles made from processed glass, typically used to enhance various products and applications. These beads come in a range of sizes and compositions, making them suitable for a variety of uses, from road safety applications to cosmetics and electronics. The term OEM signifies that these glass beads are manufactured to specific specifications for other companies, which may apply them in their final products.

One of the notable features of OEM mix glass beads is their versatility. Manufacturers can customize the size, color, and chemical properties to meet the precise needs of their clients. This customization capability not only allows for precise applications in different industries but also enables companies to differentiate their products in a competitive marketplace.

The Benefits of Collaboration

OEM mix glass beads factories often collaborate closely with their clients during the development and production phases. This partnership model fosters innovation and ensures that the final products meet rigorous industry standards. Through these collaborations, manufacturers can explore new formulations and technologies that enhance the performance of the glass beads, benefitting end-users and improving product quality.

Moreover, the collaborative approach encourages knowledge sharing and best practices, ultimately leading to enhanced production techniques. This synergy between OEM manufacturers and their clients ensures that they remain agile and responsive to market demands, thereby enhancing competitiveness in a global landscape.

Contribution to Sustainability

oem mix glass beads factories

As environmental concerns gain prominence across industries, OEM mix glass beads factories have embraced sustainability as a core principle. The production of glass beads often utilizes recycled glass, significantly reducing waste and energy consumption. This recycling process not only minimizes the carbon footprint associated with manufacturing but also promotes the circular economy by repurposing materials that would otherwise end up in landfills.

In addition to using recycled materials, many factories are adopting eco-friendly production methods. These methods focus on minimizing water usage, reducing emissions, and implementing waste reduction strategies. Some OEM manufacturers are even exploring innovative technologies such as energy-efficient furnaces and alternative fuels, further cementing their commitment to sustainability.

Industry Applications

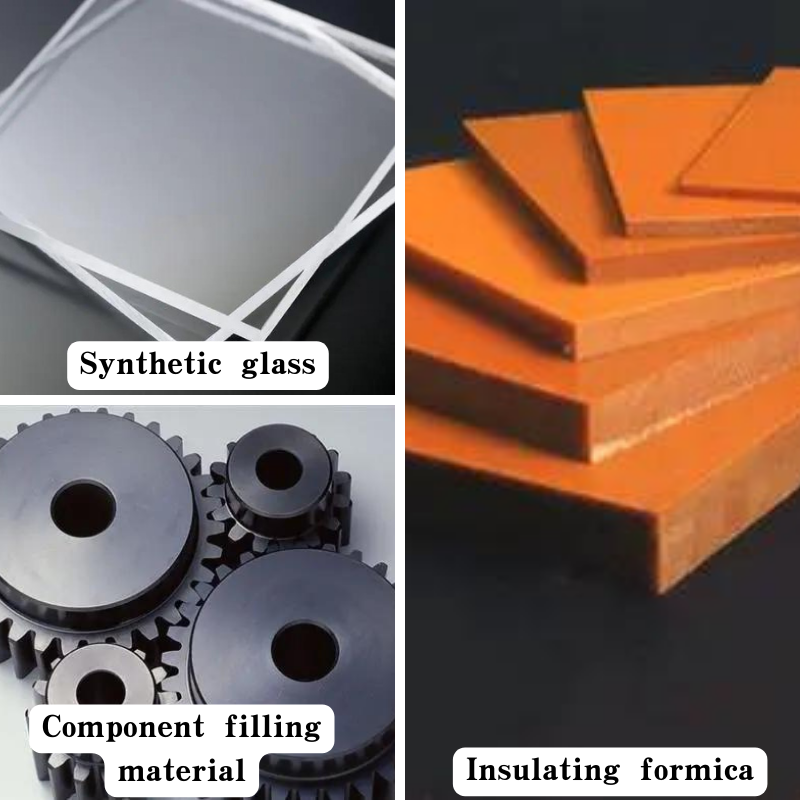

OEM mix glass beads play a vital role in various industries. For example, in the road safety sector, glass beads are used in manufacturing reflective paints and traffic signage, significantly improving visibility for drivers and pedestrians at night. Their reflective properties enhance safety while contributing to the aesthetics of urban planning.

In the cosmetics industry, glass beads serve as gentle exfoliants and texturizers in skincare products. Their unique spherical shape ensures a smooth application, making them highly desirable for cosmetic formulations. Additionally, glass beads offer a biodegradable alternative to microplastics, aligning with the industry's shift towards more sustainable ingredients.

The electronics sector also benefits from OEM mix glass beads, which are used in the production of specialized coatings and insulative materials. Their thermal and electrical properties make them essential components in various electronic devices, ensuring reliability and performance.

Conclusion

OEM mix glass beads factories exemplify the intersection of innovation and sustainability in the manufacturing landscape. Through collaboration and a commitment to environmental stewardship, these factories are not only enhancing the quality and performance of their products but also contributing to a greener future. As industries continue to evolve, the adaptability and versatility of OEM mix glass beads position them as a crucial component in a wide range of applications, ensuring safety, aesthetics, and functionality in everyday products. With continued investment in research and innovation, the future looks bright for OEM mix glass beads factories, as they lead the charge towards sustainable manufacturing practices.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025