oem mix glass beads

The Versatility of OEM Mix Glass Beads

In recent years, the use of glass beads has emerged as a significant trend in various industries, including automotive, manufacturing, and decoration. OEM (Original Equipment Manufacturer) mix glass beads are specifically designed to meet the unique requirements of different applications, bringing versatility and functionality to a wide range of products. This article will explore the benefits, applications, and manufacturing processes associated with OEM mix glass beads.

Understanding OEM Mix Glass Beads

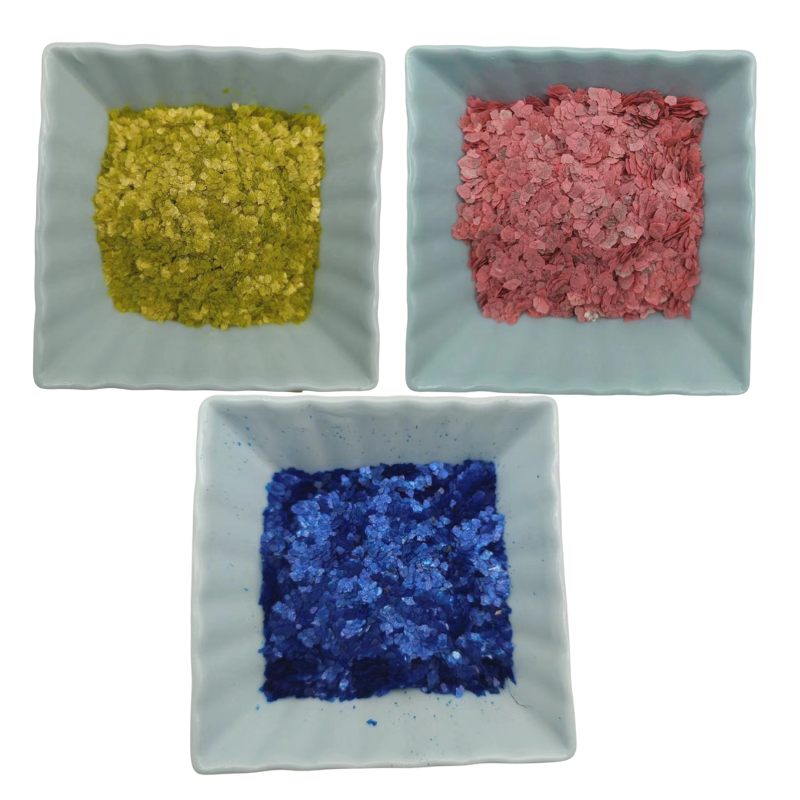

OEM mix glass beads are small spherical beads made from glass, often used as an additive or finishing option. They are produced in different sizes and colors, allowing manufacturers to customize their products according to specific needs. The term mix refers to the combination of various sizes and types of glass beads in a single product, providing enhanced performance characteristics that cater to diverse situations.

Benefits of Using OEM Mix Glass Beads

1. Durability Glass beads are known for their high durability and resistance to environmental factors. This makes them an excellent choice for applications where wear and tear are common.

2. Reflectivity One of the key features of glass beads is their ability to reflect light. When incorporated into road marking paints, these beads enhance visibility, contributing to safer driving conditions at night and in adverse weather.

3. Aesthetic Appeal OEM mix glass beads can provide a unique finish to decorative items, crafts, and jewelry. Available in various colors and finishes, they allow for creative expression in design.

oem mix glass beads

Applications of OEM Mix Glass Beads

1. Road Safety The most common use of glass beads is in traffic paints. When applied to road markings, they provide retroreflectivity, ensuring that markings are visible at night, thus improving road safety.

2. Abrasives Glass beads are widely used as an abrasive material for sandblasting and surface finishing. Their uniform size and non-toxic nature make them suitable for industries that require a clean and dust-free environment.

3. Cosmetics In the cosmetics industry, glass beads are used in exfoliating products. Their smooth texture can help gently remove dead skin cells, providing a polished and refreshed appearance.

4. Sports Equipment OEM mix glass beads can also be found in sports equipment, such as in the manufacturing of synthetic turf. They help to improve the playing experience by providing a resilient surface.

Manufacturing Process

The manufacturing of OEM mix glass beads involves several steps. First, raw materials are sourced and melted at high temperatures. The molten glass is then carefully cooled and formed into beads. The next step involves sorting the beads by size and mixing different varieties to create the desired OEM mix. Finally, they undergo quality control checks to ensure consistency in color, size, and performance.

Conclusion

OEM mix glass beads are a remarkable innovation that caters to various industries and applications. Their durability, reflectivity, and aesthetic appeal make them invaluable for enhancing safety, improving product functionality, and providing design flexibility. As manufacturers continue to explore new uses for these beads, the potential for innovation remains vast, ensuring that OEM mix glass beads will play a crucial role in future advancements across multiple sectors.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025