oem marble powder manufacturers

The Rising Demand for OEM Marble Powder Manufacturers

In the world of construction and interior design, the use of marble has long been synonymous with luxury and elegance. Marble, with its unique patterns and rich variety of colors, has established itself as a preferred choice for a wide range of applications. However, the demand for innovative, cost-effective alternatives has led to a surge in the popularity of marble powder—a byproduct of the marble industry that possesses numerous advantages. As a result, the segment of OEM marble powder manufacturers has seen a significant rise in interest and investment.

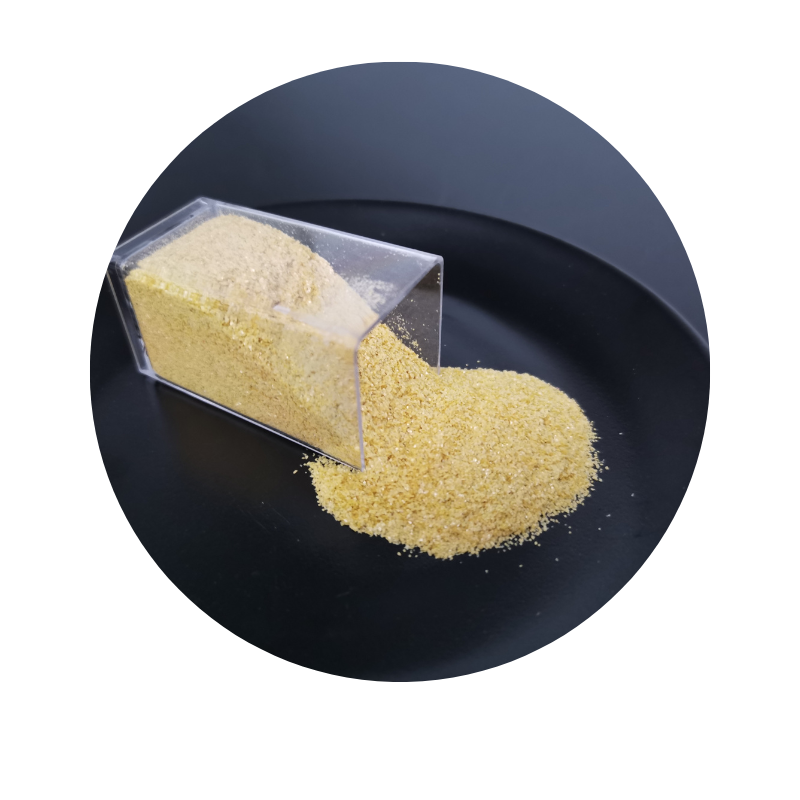

Understanding Marble Powder

Marble powder is produced through the crushing and grinding of marble stone. This fine powder retains the color and texture characteristics of marble but offers enhanced versatility in its applications. It is an eco-friendly product that not only helps in the recycling of marble waste but also opens the door for a host of industry uses ranging from construction materials to decorative arts.

The use of marble powder has gained traction in various sectors such as construction, ceramics, plastics, and even cosmetics. In construction, it serves as a filler material to enhance the mechanical properties of cement and concrete. The fine particles provide better workability, increase compressive strength, and improve durability, making it a valuable additive for manufacturers. In the ceramics industry, marble powder is used to produce tiles, porcelain, and pottery, giving finished products a distinctive finish that mimics the elegance of natural stone.

The Role of OEM Manufacturers

OEM (Original Equipment Manufacturer) marble powder manufacturers play a vital role in providing high-quality marble powder tailored to meet the specific needs of various industries. By collaborating with different companies, these manufacturers can offer customized solutions that ensure the optimal performance of their products in end-use applications.

The emergence of OEM partnerships has allowed businesses to leverage the expertise of specialized manufacturers, ensuring that they receive marble powder that meets strict quality standards and compliance regulations. This not only enhances the reputation of the companies involved but also contributes to sustainability efforts by promoting the reuse of industrial waste.

oem marble powder manufacturers

Advantages of Partnering with OEM Manufacturers

1. Customization OEM manufacturers can customize marble powder based on particle size, purity, and other properties required by specific industries, ensuring that businesses get exactly what they need.

2. Quality Assurance Working with experienced OEMs means that companies can benefit from strict quality control processes, helping to maintain the reliability of their products.

3. Cost-Effectiveness By outsourcing the production of marble powder, companies can reduce operational costs related to manufacturing while gaining access to specialized knowledge and technology.

4. Sustainability OEM manufacturers often prioritize eco-friendly practices, ensuring that the production process is as sustainable as possible and contributing to the circular economy.

Conclusion

The increasing use of marble powder across various sectors signifies a shift towards more sustainable practices in construction and manufacturing. As the demand for high-quality marble powder continues to rise, the role of OEM marble powder manufacturers becomes increasingly critical. By offering tailored solutions, these manufacturers not only meet the specific needs of their partners but also contribute to a more sustainable and innovative industry landscape. Organizations looking to enhance their product offerings and optimize their operations would do well to consider collaboration with OEM marble powder manufacturers as a strategic move.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025