oem expanded vermiculite factories

The Expansion of OEM Expanded Vermiculite Factories Enhancing Production and Sustainability

In recent years, the demand for expanded vermiculite has surged, driven by its versatility and eco-friendly properties. This lightweight, mineral-based product is widely used in construction, gardening, and various industrial applications due to its excellent insulation, soundproofing, and moisture-retention qualities. As a result, many OEM (Original Equipment Manufacturer) expanded vermiculite factories are expanding their operations to meet the growing market needs.

The Importance of Expanded Vermiculite

Expanded vermiculite is produced by heating raw vermiculite mineral ore, causing it to expand into lightweight, aerated particles. This unique structure provides exceptional thermal and acoustic insulation, making it ideal for use in buildings and homes. Furthermore, its inert nature makes it safe for gardening and horticultural applications, as it improves soil aeration and moisture retention without introducing harmful chemicals.

The rise in green building practices and sustainable gardening has further fueled the demand for expanded vermiculite. As consumers become more environmentally conscious, they are seeking out products that reduce their carbon footprint and promote sustainability. OEM expanded vermiculite factories play a crucial role in ensuring a steady supply of this eco-friendly material.

The Expansion of OEM Factories

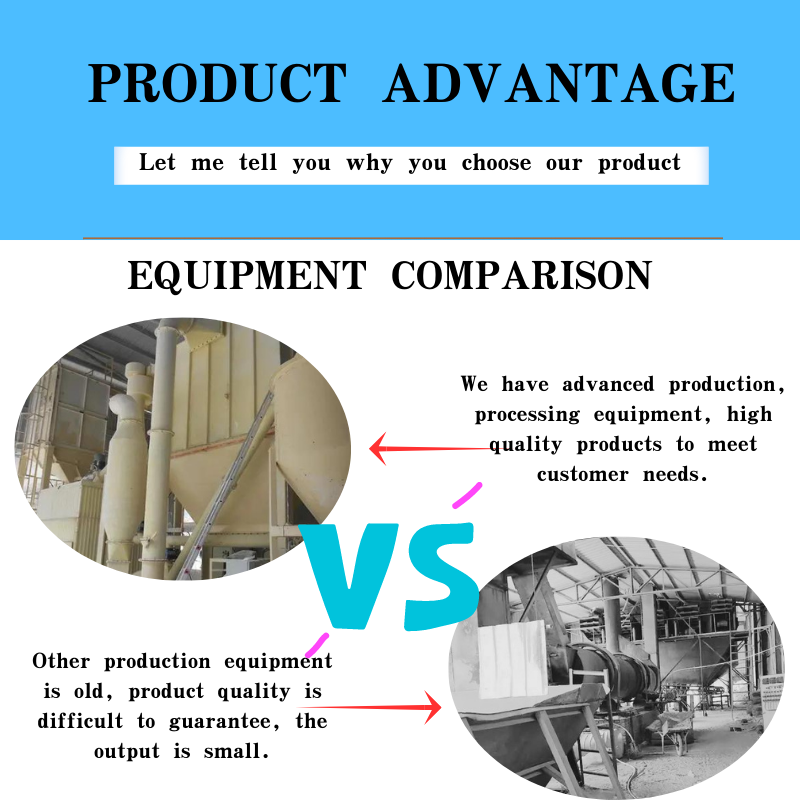

To capitalize on the growing market, many OEM manufacturers are expanding their vermiculite production facilities. This expansion often includes upgrading machinery, increasing raw material sourcing, and improving production processes to enhance efficiency. By investing in state-of-the-art technology, these factories can produce higher quality vermiculite at a lower cost, thereby meeting the increasing demand without compromising on quality.

oem expanded vermiculite factories

Additionally, OEM factories are focusing on expanding their product range to cater to diverse customer needs. For instance, they are developing specialized vermiculite products for specific applications, such as horticulture, roofing, and fireproofing. This diversification not only helps in attracting a broader customer base but also strengthens the factories’ market position.

Sustainability Initiatives

As the demand for expanded vermiculite grows, so does the emphasis on sustainability within OEM factories. Many manufacturers are adopting eco-friendly practices to minimize their environmental impact. This includes sourcing raw materials responsibly, reducing waste, and implementing energy-efficient production processes.

Furthermore, some OEM expanded vermiculite factories are exploring innovative recycling techniques to repurpose waste materials generated during production. This approach not only reduces waste but also supports the circular economy by creating new resources from byproducts.

Conclusion

The expansion of OEM expanded vermiculite factories reflects the growing appreciation for sustainable building materials and gardening solutions. By investing in advanced production technologies and committed to environmentally responsible practices, these manufacturers are well-positioned to meet the rising demand for expanded vermiculite. As the market continues to evolve, the role of OEM factories will be crucial in providing high-quality, sustainable solutions that benefit both consumers and the planet.

In summary, the future of OEM expanded vermiculite factories looks bright. With a focus on efficiency, diversification, and sustainability, these factories are not only responding to the current market trends but are also paving the way for a more sustainable future in construction and horticulture. As more industries recognize the value of expanded vermiculite, the importance of these factories will only continue to grow.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025