OEM Large Mica Flakes Manufacturer | High-Quality Mica Products

The Significance of OEM Large Mica Flakes Manufacturers

Mica, a naturally occurring mineral, has garnered significant attention in various industries due to its unique properties, including thermal resistance, electrical insulation, and excellent translucency. Within the mica industry, Original Equipment Manufacturer (OEM) large mica flakes are particularly valued for their application in diverse sectors such as cosmetics, construction, automotive, and electronics. The role of OEM large mica flakes manufacturers is crucial as they provide high-quality, customized products that meet specific customer requirements.

Understanding OEM Manufacturing

OEM refers to companies that design and manufacture products based on the specifications of another company, which then sells them under its brand. In the case of large mica flakes, manufacturers engage in the sourcing, processing, and refinement of mica to produce customized flakes according to the precise dimensions and qualities desired by their clients. This tailored approach allows businesses to incorporate these flakes into their products with minimal investment in equipment or raw materials.

Applications of Large Mica Flakes

Large mica flakes are particularly sought after for their aesthetic and functional properties. In the cosmetics industry, for instance, they are widely used as natural fillers and extenders in makeup products such as eyeshadows, blushes, and foundations. Their ability to scatter light helps in enhancing the appearance of skin by providing a shimmering effect, which makes them a staple in beauty formulations.

In construction, large mica flakes serve as effective reinforcing materials. They improve the mechanical strength and thermal stability of products like asphalt, cement, and drywall, making structures more resilient. Furthermore, their chemical inertness makes them suitable for high-temperature applications, ensuring durability and longevity.

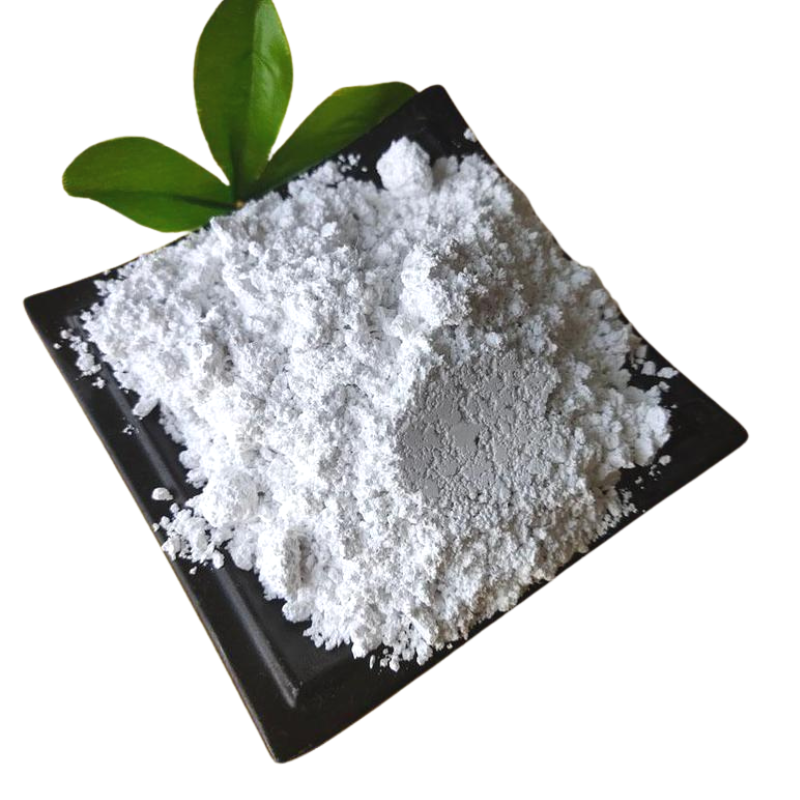

oem large mica flakes manufacturer

The automotive sector also greatly benefits from large mica flakes, utilizing them in various components such as brake linings and electrical insulation materials. Their excellent dielectric properties contribute to the safety and efficiency of electrical systems within vehicles.

The Importance of Quality and Sourcing

As the demand for high-quality mica increases, the role of OEM large mica flakes manufacturers becomes even more vital. These manufacturers must focus on sourcing mica from reputable mines and ensuring that it is processed to meet stringent quality standards. The purity and size of mica flakes directly impact their performance in end products, making it essential for manufacturers to employ rigorous quality control measures throughout the production process.

Sustainability is also an emerging concern in the mica industry. Ethical sourcing and environmentally responsible mining practices are critical. OEM manufacturers are increasingly required to demonstrate their commitment to ethical practices, ensuring that the mica they supply is sourced from mines that do not exploit workers and minimize environmental impacts.

Conclusion

In summary, OEM large mica flakes manufacturers play a pivotal role in various industries by providing high-quality, customized mica products that cater to specific needs. Their significance extends from enhancing beauty products to reinforcing construction materials and contributing to automotive safety. As the market continues to evolve, these manufacturers must prioritize quality and sustainability to meet the demands of an environmentally conscious consumer base. As they adapt to these challenges, OEM large mica flakes manufacturers are poised to remain integral to the mica supply chain for years to come.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025