OEM Calcined Kaolin Production Facility for Quality Industrial Applications and Customized Solutions

The Significance of OEM Calcined Kaolin Factories in Modern Industries

Calcined kaolin, a versatile clay mineral, is obtaining increasing popularity in various industries, including ceramics, paper, rubber, and plastics. The unique properties of calcined kaolin, such as its brightness, low abrasiveness, and chemical inertness, make it an invaluable raw material. Original Equipment Manufacturer (OEM) calcined kaolin factories play a pivotal role in supplying high-quality materials tailored to meet the specific needs of diverse applications and industries.

Understanding Calcined Kaolin

Calcined kaolin is derived from the thermal treatment of kaolin clay at high temperatures. This process removes water molecules and crystallizes the clay, resulting in a fine, white powder. The calcination process enhances its properties, making it more suitable for applications that require durability, strength, and chemical stability.

In the paper industry, calcined kaolin is widely used as a coating pigment, improving the paper's brightness, opacity, and smoothness. These attributes are crucial for achieving high-quality printed materials. Similarly, in the ceramics industry, calcined kaolin is vital for producing whiteware and porcelain, imparting strength and improving the firing properties of the final product.

The Role of OEM Calcined Kaolin Factories

OEM calcined kaolin factories specialize in customizing production to fit specific client requirements. These factories collaborate closely with businesses to develop formulations that cater to their unique applications. This customization ensures that clients receive the ideal materials tailored to their needs, optimizing product performance.

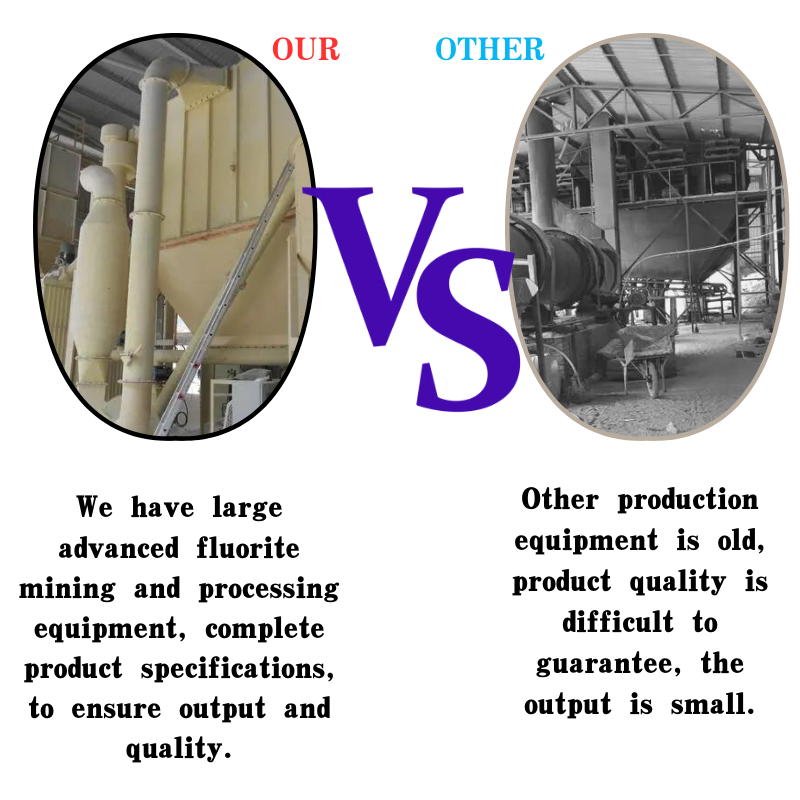

One of the key advantages of working with OEM factories is the ability to scale production efficiently without compromising quality. These factories are equipped with advanced technology and equipment, enabling them to produce large volumes of calcined kaolin while maintaining stringent quality control standards. This ensures that clients receive consistent quality in each batch, vital for maintaining production efficiency in their operations.

oem calcined kaolin factory

Environmental Considerations

With the growing emphasis on sustainability, OEM calcined kaolin factories are increasingly adopting environmentally friendly practices. Innovations in production techniques and waste management help reduce the environmental footprint. For instance, many factories have implemented closed-loop systems that minimize water usage and manage waste effectively, aligning with global sustainability goals.

Moreover, the natural abundance of kaolin clay presents an opportunity for factories to source materials sustainably. By prioritizing local sourcing, OEM factories can reduce transportation emissions and support local economies, thereby contributing to more sustainable industry practices.

Challenges and Future Prospects

Despite the many advantages, OEM calcined kaolin factories face challenges such as fluctuating raw material prices and increasing competition. To stay ahead, these factories must continually invest in research and development. Innovations in processing techniques and the exploration of new applications for calcined kaolin can help these facilities expand their market reach and maintain relevance in an evolving marketplace.

The demand for high-quality calcined kaolin is anticipated to grow, driven by expansion in industries such as construction, automotive, and packaging. As businesses increasingly recognize the value of using premium materials, the role of OEM manufacturers will become even more critical in shaping the future of these sectors.

Conclusion

OEM calcined kaolin factories are essential contributors to various industries, providing high-quality, customized materials that enhance product performance. With their commitment to sustainability and innovation, these factories are well-positioned to meet the future demands of the market, ensuring that calcined kaolin continues to be a key player in industrial applications. As the global economy evolves, the importance of these factories will only increase, reinforcing their role as indispensable partners in manufacturing and production.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025