oem calcined kaolin factories

The Rise of OEM Calcined Kaolin Factories

In recent years, calcined kaolin has emerged as a critical material in various industries, including ceramics, paints, plastics, and rubber. The growing demand for high-quality kaolin products has led to the proliferation of Original Equipment Manufacturer (OEM) calcined kaolin factories, which focus on producing customized kaolin solutions tailored to meet specific client needs.

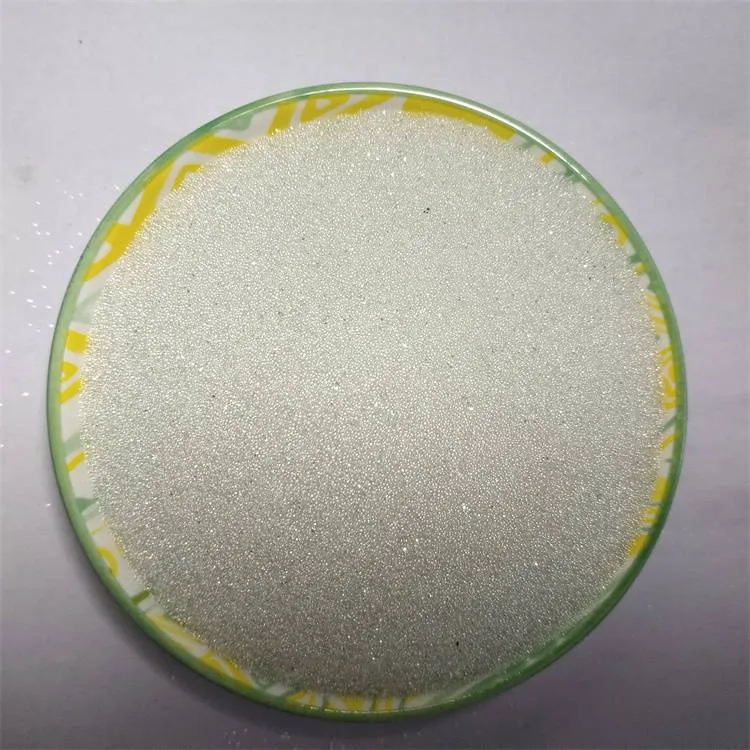

Calcined kaolin, a high-purity and high-stability form of kaolin obtained through a process of controlled calcination, is known for its unique properties. It enhances product performance, improves durability, and contributes to the aesthetic appeal of end products. As industries strive for higher efficiency and lower production costs, the role of OEM factories becomes increasingly significant. By leveraging advanced processing techniques and innovative manufacturing processes, these factories are able to deliver desirable kaolin products that meet stringent market requirements.

The Rise of OEM Calcined Kaolin Factories

Furthermore, OEM factories typically possess a deep understanding of the markets they serve. They are well-versed in compliance with international regulations and standards, ensuring that their products not only meet but exceed industry expectations. This compliance is crucial for businesses that operate in highly regulated sectors, such as the food industry, where the use of certain materials must adhere to strict safety guidelines.

oem calcined kaolin factories

In addition to quality and compliance, cost effectiveness is another critical factor driving industries toward OEM calcined kaolin factories. These factories can achieve economies of scale that independent manufacturers often cannot. By streamlining production processes and optimizing supply chain management, OEM factories enable their clients to lower manufacturing costs while maintaining high-quality standards. This cost efficiency can significantly impact a company’s bottom line, making it an attractive proposition for businesses seeking to maximize profitability.

Moreover, as sustainability becomes a growing concern globally, OEM calcined kaolin factories are increasingly implementing eco-friendly practices. Many of these factories focus on sustainable sourcing of raw materials, waste reduction, and energy-efficient production methods. By partnering with environmentally conscious OEM suppliers, businesses not only contribute to sustainability efforts but also enhance their brand image in a market that values corporate responsibility.

Ultimately, the rise of OEM calcined kaolin factories signifies a shift towards more specialized and efficient production processes in multiple industries. As the demand for calcined kaolin continues to grow, these factories are poised to play a pivotal role in shaping the future of material manufacturing. By offering customized solutions, ensuring compliance, achieving cost efficiency, and adopting sustainable practices, OEM calcined kaolin factories are not just suppliers; they are strategic partners that empower businesses to innovate and thrive in a competitive landscape.

In conclusion, the evolution of OEM calcined kaolin factories represents a significant development in the materials sector. As industries seek to optimize their products and processes, these factories provide essential support through advanced technology, customization, and sustainability initiatives, confirming their importance in the modern manufacturing ecosystem.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025