Micro Silica Fume Suppliers & Manufacturers | High-Quality Micro Silica

Micro silica fume, also known simply as silica fume, is a byproduct derived from the production of silicon metal or ferrosilicon alloys. Its unique characteristics make it an essential additive in the construction and engineering industries, particularly in enhancing the performance of concrete. As sustainability continues to gain importance in modern construction methods, the demand for micro silica fume is on the rise. This article will delve into the role of micro silica fume suppliers and manufacturers in the market.

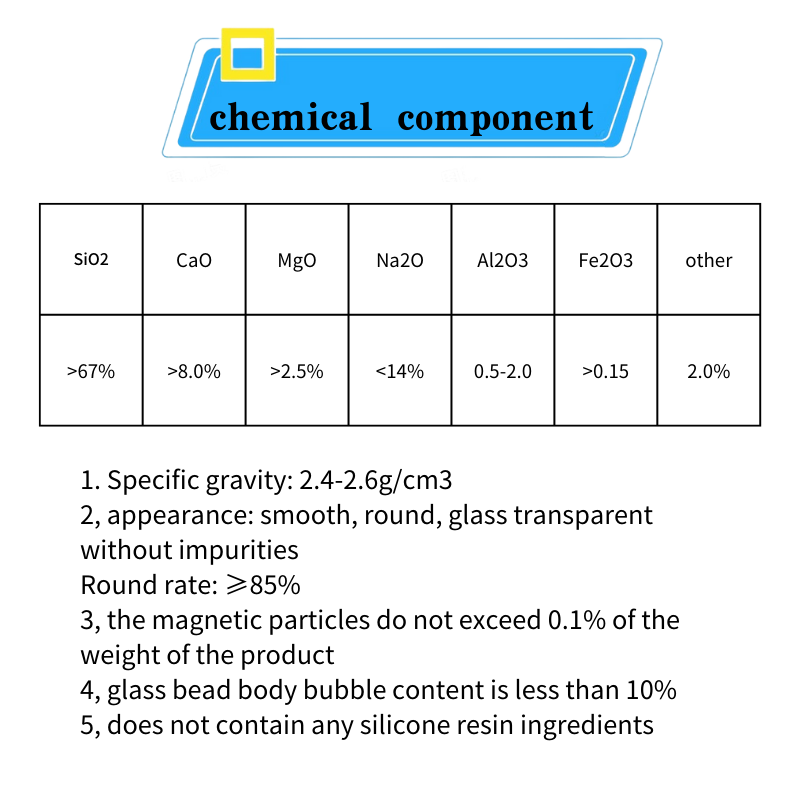

Micro silica fume is predominantly composed of fine particles of silicon dioxide, which are approximately 100 times smaller than that of ordinary cement. This fineness allows silica fume to fill the voids in concrete, thus improving its density and strength. Furthermore, it enhances the durability of concrete against acids and other aggressive chemicals, making it ideal for infrastructure projects such as bridges, dams, and industrial flooring.

Suppliers and manufacturers of micro silica fume play a crucial role in ensuring the consistent quality and availability of this vital material. Increasingly, they are adopting more sustainable practices in their operations, sourcing raw materials responsibly, and minimizing waste. This aligns with the global push towards eco-friendly construction practices, driving innovation in the production processes of micro silica fume.

The market for micro silica fume is diverse, with applications ranging from high-performance concrete to precast concrete products. Manufacturers often provide customized solutions to meet specific project requirements. This adaptability is key in sectors like precast concrete, where manufacturers may need varying grades of silica fume to achieve desired performance characteristics.

micro silica fume suppliers manufacturers

When selecting micro silica fume suppliers, several factors must be considered product quality, consistency, and service reliability. Established suppliers often provide detailed technical data sheets, ensuring that contractors and engineers have the necessary information for optimal application. Moreover, strong customer support can facilitate the integration of silica fume into various concrete mixes, ensuring that projects meet industry standards.

Furthermore, leading micro silica fume manufacturers invest in research and development to enhance their offerings. Innovations in processing techniques aim to create micro silica fume products that enhance performance while reducing carbon footprints. As a result, these companies not only contribute to the strength and durability of concrete but also support the overarching goals of sustainability in construction.

In conclusion, micro silica fume suppliers and manufacturers are critical players in the construction industry, providing high-quality products that enhance concrete performance while promoting sustainable practices. The increasing demand for such materials underscores their importance in modern construction, paving the way for innovative solutions that align with environmental responsibilities. As the industry continues to evolve, these suppliers will undoubtedly remain at the forefront of change, supporting the development of resilient and sustainable infrastructure.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025