1 月 . 20, 2025 02:25

Back to list

black mica crystal

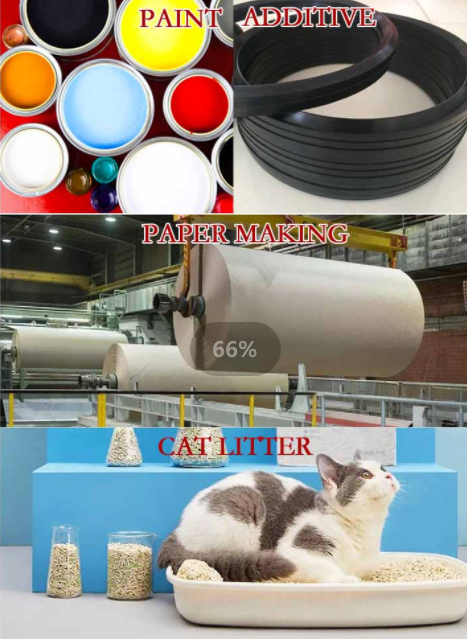

Mica sheets have become indispensable components in various industrial applications, standing as a testament to their exceptional properties and versatility. These thin layers of mica mineral, a group comprised primarily of muscovite and phlogopite, offer unique benefits that align perfectly with the demands of modern engineering and high-tech environments.

Trust in mica sheets is further elevated by their eco-friendly credentials. Being a naturally occurring mineral, mica is recyclable and less harmful to the environment compared to synthetic alternatives. Businesses increasingly seek to incorporate eco-conscious practices into their production lines, and using mica sheets supports sustainable manufacturing efforts. Considerations for selecting the right type of mica include evaluating specific industrial needs against available mica variants—muscovite for its electric insulation and phlogopite for thermal stability. While muscovite is transparent and ideal for applications requiring high‑quality optics, phlogopite offers optimal performance in settings demanding higher thermal endurance. As the global market evolves, so does the need for innovative uses of mica sheets. Emerging technologies like renewable energy systems and electric vehicles further open opportunities for mica's application, due to its capacity to withstand significant temperature fluctuations and its overall resistance to wear and tear. In summary, mica sheets stand out as a leading material for industrial and technological innovations, offering unmatched insulation capabilities, reliability under duress, and compatibility with sustainable practices. For manufacturers seeking durable, efficient, and green alternatives, the authority and trust vested in mica sheets are undeniably compelling. With a deep-rooted history of delivering safety and performance, mica sheets continue to shape the future of industrial applications, making them indispensable in our quest for technological superiority.

Trust in mica sheets is further elevated by their eco-friendly credentials. Being a naturally occurring mineral, mica is recyclable and less harmful to the environment compared to synthetic alternatives. Businesses increasingly seek to incorporate eco-conscious practices into their production lines, and using mica sheets supports sustainable manufacturing efforts. Considerations for selecting the right type of mica include evaluating specific industrial needs against available mica variants—muscovite for its electric insulation and phlogopite for thermal stability. While muscovite is transparent and ideal for applications requiring high‑quality optics, phlogopite offers optimal performance in settings demanding higher thermal endurance. As the global market evolves, so does the need for innovative uses of mica sheets. Emerging technologies like renewable energy systems and electric vehicles further open opportunities for mica's application, due to its capacity to withstand significant temperature fluctuations and its overall resistance to wear and tear. In summary, mica sheets stand out as a leading material for industrial and technological innovations, offering unmatched insulation capabilities, reliability under duress, and compatibility with sustainable practices. For manufacturers seeking durable, efficient, and green alternatives, the authority and trust vested in mica sheets are undeniably compelling. With a deep-rooted history of delivering safety and performance, mica sheets continue to shape the future of industrial applications, making them indispensable in our quest for technological superiority.

Share

Next:

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025