Leading Manufacturers of Microsilica and Silica Fume Powder in China for Construction Applications

An Insight into China’s Microsilica and Silica Fume Powder Factories

In recent years, China has become a global leader in the production of microsilica and silica fume, two essential materials widely used in various industrial applications. This growth can be attributed to the rapid expansion of the construction, automotive, and electronics industries, which utilize these materials for their unique properties. This article explores the significance of microsilica and silica fume, the manufacturing processes employed by Chinese factories, and the implications for both domestic and international markets.

An Insight into China’s Microsilica and Silica Fume Powder Factories

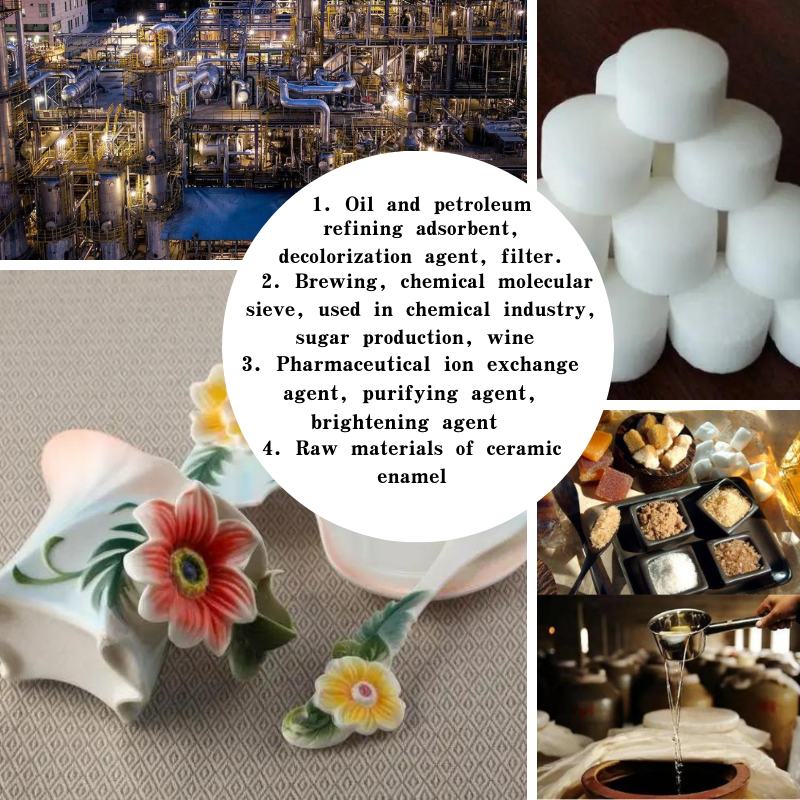

China's silica fume powder factories leverage advanced manufacturing techniques to produce high-quality microsilica. The production process generally involves collecting the silica fume generated during the smelting of silicon alloys and subjecting it to various processing methods to obtain the desired purity and particle size. The fine particles are often bagged and transported to construction sites or further processed for use in specialized applications such as refractory materials, ceramics, and electronic components.

china microsilica silica fume powder factories

With China being home to numerous silica fume factories, these facilities play a crucial role in meeting both domestic and international demand. The country boasts a vast number of suppliers capable of producing large volumes of microsilica to cater to its booming construction sector. This has resulted in increased competition among manufacturers, leading to enhancements in product quality and reductions in production costs. Furthermore, many factories have adopted environmentally friendly practices, including waste recycling and efficient energy use, aligning with the global trend towards sustainability.

In addition to serving the local market, Chinese microsilica producers are increasingly exporting their products worldwide. As construction and infrastructural projects initiate in developing countries, demand for high-performance concrete continues to grow. China's capability to produce and deliver microsilica efficiently positions it as a leading supplier in the global market. Trade agreements and international relationships have further facilitated these exports, enabling Chinese factories to expand their reach globally.

While the benefits of microsilica are substantial, challenges remain in terms of safety and environmental concerns. Some silica fume particles, if inhaled, can pose health risks to workers. Consequently, factories are implementing strict safety measures and investing in worker training to mitigate these hazards. Additionally, the industry faces pressure to adhere to environmental regulations, ensuring that production processes do not harm local ecosystems. Innovations in production technology aim to minimize emissions and enhance the sustainability of the manufacturing practices.

In conclusion, China’s microsilica and silica fume powder factories play a pivotal role in the construction industry and beyond. Their production capabilities not only support local infrastructure development but also foster international trade. As the demand for high-performance materials continues to rise globally, these factories are well-positioned to meet future challenges through innovations, sustainable practices, and adherence to safety standards. The evolution of this sector will undoubtedly contribute to shaping a more resilient and sustainable built environment for the future.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025