Leading Manufacturers of Calcium Carbonate for Various Industrial Applications and Quality Standards

Understanding Calcium Carbonate Manufacturers A Look into the Industry

Calcium carbonate is a fundamental chemical compound with the formula CaCO3. It is found naturally in minerals such as calcite and aragonite and is a major component of limestone and marble. Due to its diverse applications across various industries, calcium carbonate is one of the most widely used minerals in the world. This article delves into the significance of calcium carbonate manufacturers, their production processes, and the various applications of calcium carbonate.

The Role of Calcium Carbonate Manufacturers

Calcium carbonate manufacturers play a vital role in supplying this compound to a variety of sectors, including construction, agriculture, pharmaceuticals, and food processing. The process of manufacturing calcium carbonate involves quarrying natural deposits of limestone, followed by grinding and processing it to achieve the desired particle size and purity.

Manufacturers can produce different grades of calcium carbonate, including precipitated calcium carbonate (PCC) and ground calcium carbonate (GCC). PCC is created through a chemical process that involves the carbonation of lime, while GCC is produced by grinding natural limestone. Each of these forms has distinct properties that make them suitable for specific applications.

Manufacturing Process

The manufacturing process of calcium carbonate typically starts with the extraction of limestone from quarries. This rock is then crushed and ground to specific particle sizes. In the case of PCC, the crushed limestone undergoes a thorough chemical process where it is treated with carbon dioxide. This results in a fine powder that is extremely pure and uniform in size, ideal for high-demand applications like pharmaceuticals and food additives.

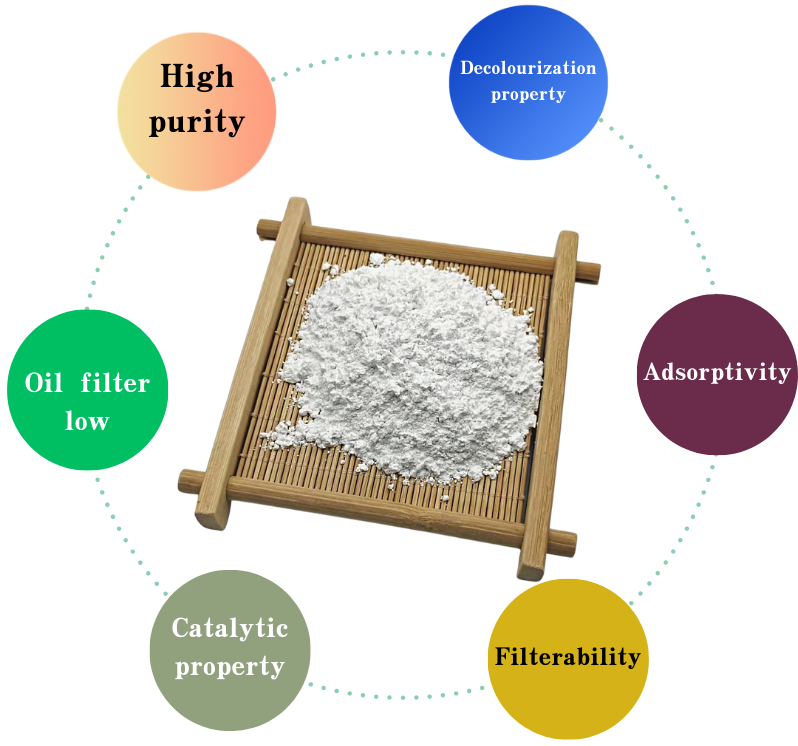

Quality control is crucial in the manufacturing process, as the purity and consistency of calcium carbonate affect its usability in various applications. Manufacturers often invest in advanced technology and equipment to ensure they can produce high-quality products that meet international standards.

Applications of Calcium Carbonate

carbonate calcium manufacturers

The versatility of calcium carbonate is evident from its wide range of applications

1. Construction Calcium carbonate is a primary ingredient in cement and is used as a building material. Its high durability and low cost make it a staple in the construction industry.

2. Agriculture In agriculture, calcium carbonate is used to improve soil quality and neutralize acidic soils. It helps in providing essential nutrients to crops, promoting better growth and yield.

3. Pharmaceuticals and Food Industry In pharmaceuticals, calcium carbonate serves as an antacid and a calcium supplement. It is used in tablets and powders, providing essential calcium for bone health. In the food industry, it is often employed as a food additive and a calcium fortifier.

4. Paper and Plastic Manufacturing GCC and PCC are used as fillers and coating agents in paper and plastic products. Their ability to improve the strength and opacity of paper makes calcium carbonate indispensable in these industries.

5. Personal Care Products Calcium carbonate can be found in various cosmetics and personal care products. It is commonly used as a mild abrasive in toothpaste, helping to remove plaque and stains.

Conclusion

Calcium carbonate manufacturers are essential contributors to the global economy, providing a crucial component that supports a multitude of industries. The versatility and wide-ranging applications of calcium carbonate make it a valuable raw material that will continue to be in demand. As industries evolve and seek sustainable solutions, the role of these manufacturers will undoubtedly expand, focusing on innovative production methods and environmentally friendly practices to meet the growing needs of the market. In this ever-evolving landscape, calcium carbonate stands as a testament to the intersection of nature and industry, highlighting the importance of natural resources in modern manufacturing.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025