Innovations in Microsilica Production Techniques and Their Industrial Applications Today

The Production of Microsilica A Comprehensive Overview

Microsilica, also known as microsilica fume or silica fume, is a byproduct of the silicon and ferrosilicon alloy production processes. It has garnered significant attention in the construction and manufacturing industries due to its unique properties and benefits. The production of microsilica is an intricate process that involves the careful collection and processing of silica particles, allowing for a variety of applications, especially in enhancing concrete quality.

Production Process

The production of microsilica occurs primarily in electric arc furnaces, where raw materials like quartz and carbonaceous reductants are subjected to high temperatures (about 1,500 to 2,000 degrees Celsius). During this process, silicon dioxide (SiO2) is reduced, resulting in the formation of silicon metal and ferrosilicon. The non-condensable gases generated during this reaction contain fine silica particles, which are released into the atmosphere as silicic fumes.

To capture these silica fumes, a sophisticated collection system is employed. Electrostatic precipitators and bag filters are commonly used to separate and filter the extremely fine particles from the gases before they are discharged into the environment. The collected microsilica is then subjected to further processing, including drying and grinding, to achieve the desired particle size for industrial use.

Key Properties and Benefits

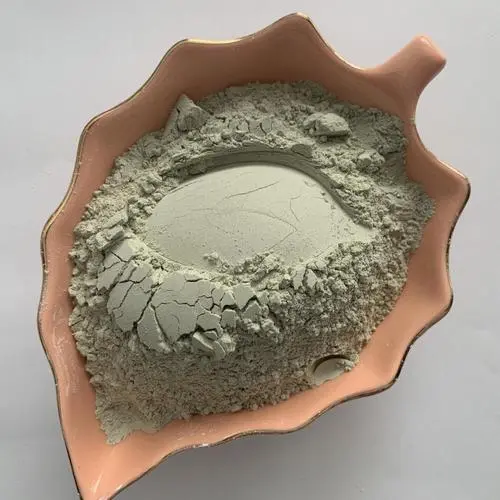

Microsilica consists of ultra-fine silica particles with an average diameter of approximately 0.1 micrometers. Its high pozzolanic activity is one of the key attributes that makes it highly valued in construction. When microsilica is added to cement-based materials, it reacts with calcium hydroxide to form additional cementitious compounds, enhancing the overall strength and durability of the concrete.

microsilica production

Incorporating microsilica into concrete mixtures offers several advantages 1. Enhanced Strength and Durability Concrete containing microsilica exhibits significantly improved compressive strength and tensile strength, resulting in structures that can withstand harsh conditions. 2. Reduced Permeability The fine particles fill the voids in the concrete matrix, leading to a denser and less permeable material. This mitigates issues related to freeze-thaw cycles, sulfate attack, and corrosion of reinforcing steel. 3. Improved Workability Microsilica acts as a plasticizer, enhancing the workability of fresh concrete, which allows for easier handling and finishing. 4. Sustainability By using microsilica as a partial replacement for cement, the carbon footprint of concrete production can be reduced, promoting more sustainable construction practices.

Applications

The versatility of microsilica extends to various sectors. In the construction industry, it is widely employed in high-performance concrete, precast concrete products, and shotcreting applications. Its ability to increase the longevity of structures makes it an ideal choice for bridges, tunnels, and high-rise buildings.

Beyond construction, microsilica is also used in manufacturing high-performance composites, coatings, and specialty ceramics. Its unique properties make it valuable in enhancing the performance characteristics of these materials, leading to innovations across numerous disciplines.

Conclusion

The production of microsilica represents a remarkable integration of industrial processes and environmental responsibility. By capturing what would otherwise be an atmospheric pollutant and transforming it into a high-value material, the microsilica industry not only contributes to the advancement of modern construction techniques but also plays a role in promoting sustainability. As both awareness and demand for high-quality construction materials continue to rise, the role of microsilica will undoubtedly expand, paving the way for more resilient and sustainable infrastructures.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025