hydrated lime types

Understanding Hydrated Lime Types A Comprehensive Overview

Hydrated lime, also known as calcium hydroxide (Ca(OH)₂), is a vital chemical compound widely used in various industries, including construction, environmental management, and agriculture. Produced by adding water to quicklime (calcium oxide), hydrated lime can be found in multiple forms, which can significantly influence its properties and applications. In this article, we explore the types of hydrated lime and their distinctive characteristics, benefits, and uses.

Types of Hydrated Lime

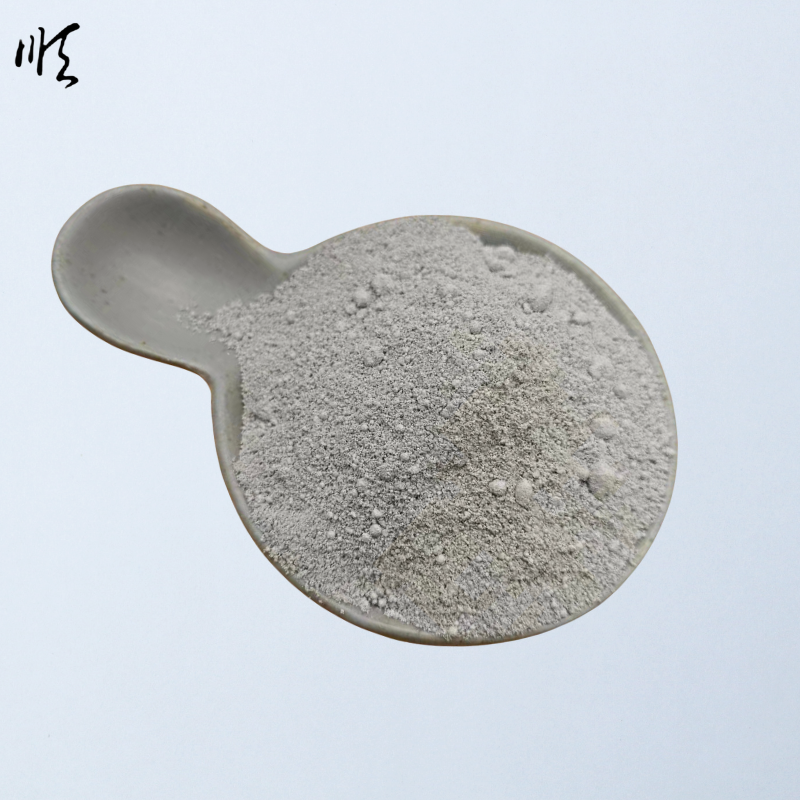

1. Dry Hydrated Lime Dry hydrated lime is the most common form and is produced through the controlled addition of water to quicklime. The resulting product is a fine, dry powder that becomes easily dispersed in water. This type is often used in construction, especially in the production of mortars, plasters, and as a soil stabilizer. Its versatility makes it an essential component in many civil engineering projects.

2. Slaked Lime Slaked lime is another name for hydrated lime, emphasizing the process of slaking, where quicklime is mixed with water. This type of lime is known for its high reactivity and is particularly effective in raising soil alkalinity, treating wastewater, and stabilizing unstable soils. Slaked lime can also be used in agriculture to correct soil acidity, making it a crucial resource for farmers aiming to enhance soil quality.

3. Hydrated Lime with Additives In some cases, hydrated lime is mixed with various additives to enhance its characteristics for specific applications. For example, incorporating pozzolanic materials or polymers can increase the strength and durability of cement and mortar mixtures. This variety of hydrated lime helps engineers and architects meet particular project requirements by optimizing performance and longevity.

Properties and Benefits

The properties of hydrated lime make it appealing for multiple applications. It possesses excellent alkaline properties, which help neutralize acidic conditions in soil and water. Its fine particle size improves its reactivity and effectiveness, allowing for better absorption when mixed with other substances.

hydrated lime types

One significant benefit of using hydrated lime is its role in environmental remediation. It effectively treats acidic wastewater and can help manage excess phosphorous in water bodies, promoting healthier aquatic ecosystems. Furthermore, hydrated lime is an integral component in flue gas desulfurization systems, assisting in reducing sulfur dioxide emissions from industrial plants.

Applications Across Industries

1. Construction Hydrated lime is widely used in the construction industry for producing high-quality mortars and plasters. It enhances workability, prolongs set times, and increases durability, making it a preferred choice for masons and contractors.

2. Environmental Management The environmental sector utilizes hydrated lime to treat wastewater, stabilize sludge, and neutralize acidic soil. Its ability to remove contaminants, such as heavy metals and phosphorous, helps improve water quality and protect aquatic life.

3. Agriculture Farmers rely on hydrated lime to amend soil pH levels. Adding lime to acidic soils can improve nutrient availability, enhance crop yields, and promote sustainable agricultural practices. Its slow-release properties also support long-term soil health.

4. Manufacturing Hydrated lime serves various manufacturing processes, including glass production, paper manufacturing, and the creation of certain chemicals. Its versatility allows it to play a critical role in multiple production lines.

Conclusion

Hydrated lime is a multifunctional compound that demonstrates a range of beneficial properties and applications across various industries. Understanding the different types of hydrated lime and their unique characteristics is essential for selecting the most suitable product for specific needs. As industries continue to evolve and environmental concerns grow, hydrated lime will undoubtedly remain a valuable resource, supporting sustainable practices and enhancing the quality of materials used in construction and agriculture.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025