High-Quality OEM Barite Powder for Effective Drilling Applications and Services in Mining Industry

OEM Barite Powder for Drilling A Comprehensive Overview

Barite powder, composed primarily of barium sulfate (BaSO4), is a crucial mineral in various industrial applications, especially in the drilling industry. Its unique properties, such as high density, chemical inertness, and ability to provide excellent barite weight gain, make it an essential component in the formulation of drilling fluids, particularly in oil and gas exploration. In this article, we will explore the significance of OEM (Original Equipment Manufacturer) barite powder for drilling, focusing on its applications, benefits, and market trends.

Understanding Barite Powder

Barite is a naturally occurring mineral that is widely mined and processed into a fine powder for use in diverse applications. The oil and gas industry primarily uses barite powder in drilling mud formulations to increase the weight of the mud, which is essential for controlling wellbore pressure during drilling operations. The API (American Petroleum Institute) has established specific standards for barite used in drilling fluids, necessitating suppliers to ensure their products meet these regulations.

OEM Barite Powder Quality and Customization

OEM barite powder refers to barite products manufactured to meet the specifications and requirements of specific clients. This can involve custom sourcing, processing, and packaging to ensure the barite is tailored for particular drilling applications. Companies specializing in OEM services take pride in delivering high-quality barite powders that comply with industry standards while also catering to the unique needs of their clients.

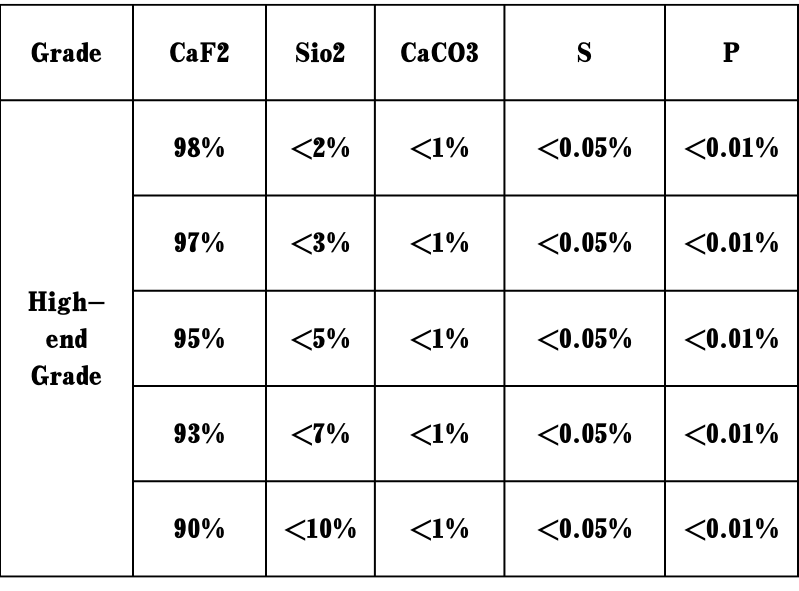

The advantages of using OEM barite powder are significant. Customization allows for 1. Quality Control Clients can specify particular grades of barite based on their drilling conditions, ensuring optimal performance. 2. Performance Optimization Tailored formulations help in enhancing various mud properties, such as viscosity, filtration control, and resistance to thermal degradation. 3. Cost Efficiency By matching the product specifications closely to operational needs, companies can save costs related to excess material usage or ineffective drilling practices.

Applications in Drilling Fluids

oem barite powder for drilling

The primary application of barite powder in drilling is as a weighting agent in drilling fluids. It enhances the density of the mud, which is critical in counteracting the pressure from geological formations. This helps prevent blowouts and stabilizes the wellbore, ensuring safer drilling operations. Additionally, barite contributes to the lubricating properties of drilling fluids, reducing friction and wear on drilling equipment.

Moreover, barite's inert nature makes it suitable for use in specialized applications, such as in the formulation of oil-based or synthetic drilling fluids, where it maintains performance without reacting negatively with other components.

Market Trends and Future Outlook

The demand for OEM barite powder continues to grow due to increased exploration activities in the oil and gas sector. As drilling techniques advance, the need for high-quality, customized barite products is becoming even more pronounced. This has led to an increase in investments in processing facilities and technologies to ensure that suppliers can meet the evolving demands of their customers.

Furthermore, with the growing emphasis on environmental sustainability, suppliers are also focusing on developing eco-friendly barite options that minimize environmental impact while maintaining performance standards.

Conclusion

OEM barite powder for drilling is a vital component in the progression of the oil and gas industry, providing enhanced performance and safety in drilling operations. With the ability to customize products to meet specific requirements, suppliers can offer significant advantages that directly impact operational efficiency and success. As the industry evolves, the demand for high-quality, performance-oriented barite products will undoubtedly continue to rise, making barite a cornerstone in the future of drilling technology.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025