glass beads for blasting manufacturer

Glass Beads for Blasting A Comprehensive Overview

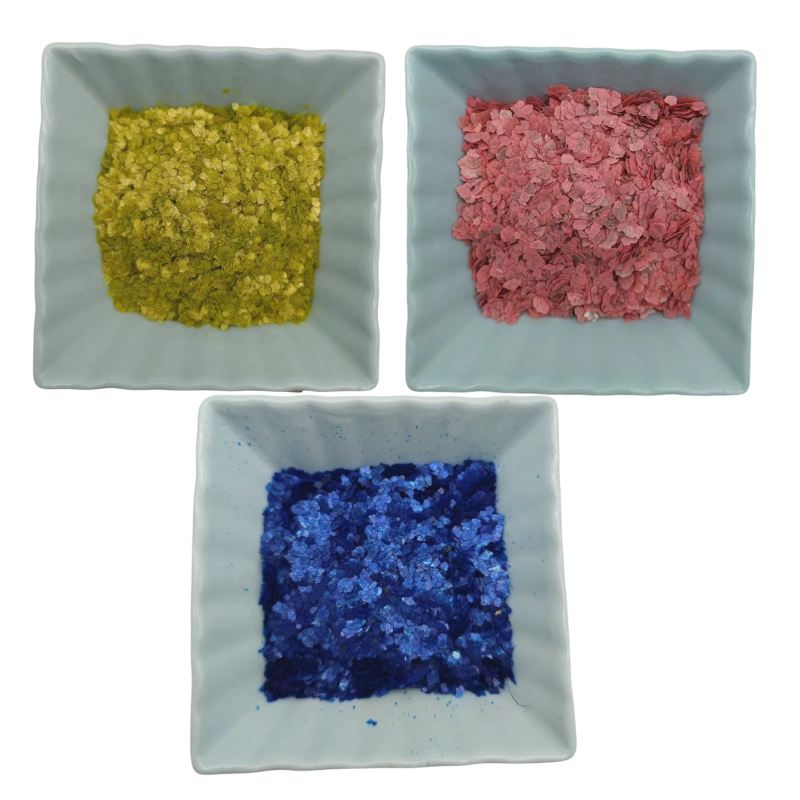

Glass beads have become an essential material in the blasting industry due to their unique properties and advantages over traditional abrasives. As a manufacturer of glass beads for blasting, it is crucial to understand their application, benefits, and the different types available in the market.

Glass bead blasting, also known as peening, involves using small glass beads propelled at high speeds to clean, polish, or smooth surfaces. This process is highly effective for various materials, including metals, plastics, and even wood. The spherical shape of the glass beads allows for a uniform surface finish, making them ideal for applications in industries such as automotive, aerospace, and manufacturing.

One of the significant benefits of glass beads is their ability to provide a non-abrasive cleaning method. Unlike harsher abrasives that can damage the substrate, glass beads gently remove unwanted contaminants without affecting the underlying material. This quality makes them highly sought after for delicate applications where preserving the substrate's integrity is paramount.

glass beads for blasting manufacturer

Environmentally friendly, glass beads are made from natural materials and are recyclable. This sustainability aspect not only reduces waste but also aligns with the growing trend of eco-conscious manufacturing practices. Companies using glass beads in their processes can enhance their sustainability profile, appealing to environmentally aware consumers and clients.

When selecting glass beads for blasting, manufacturers offer various sizes and grades to meet specific operational needs. The choice of bead size can significantly affect the outcome of the blasting process. Smaller beads are typically used for fine detail work and cleaning intricate parts, while larger beads are suited for heavier cleaning tasks and surface preparation.

Quality control is vital in the production of glass beads for blasting. Manufacturers must ensure that the beads meet specific quality standards in terms of roundness, size consistency, and absence of defects. This attention to detail guarantees optimal performance during the blasting process, leading to superior surface finishes and prolonged equipment lifespan.

In conclusion, the use of glass beads for blasting presents numerous advantages, including non-abrasiveness, environmental sustainability, and versatility in applications. As a leading manufacturer in the field, it is essential to prioritize quality and innovation to meet the evolving demands of the industry. By doing so, businesses can ensure they provide effective and environmentally friendly solutions that align with modern manufacturing practices.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025