glass beads blasting

Understanding Glass Beads Blasting A Comprehensive Overview

Glass beads blasting is a surface treatment process that utilizes small glass beads to clean, polish, or finish a variety of materials. This technique has gained popularity in various industries due to its effectiveness, efficiency, and the smooth finish it produces. In this article, we will explore what glass beads blasting is, how it works, its applications, advantages, and some considerations for those looking to incorporate this method into their operations.

What is Glass Beads Blasting?

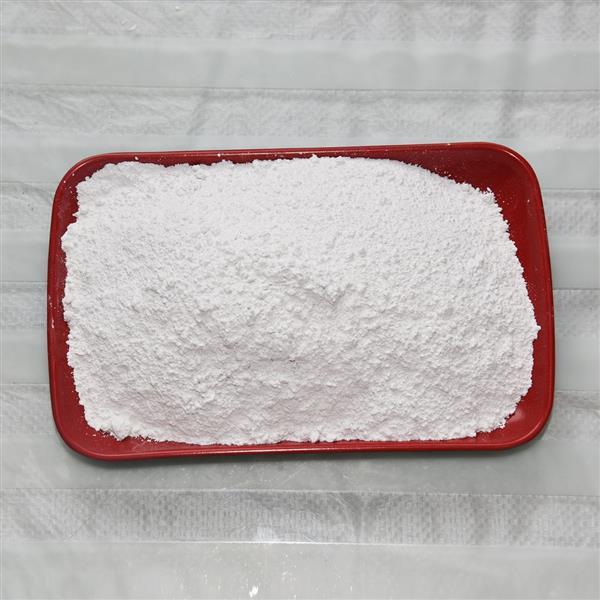

Glass beads blasting involves the use of rounded glass beads as the abrasive medium. These beads are generally manufactured from lead-free and soda-lime glass, making them an environmentally friendly choice compared to other abrasive media. The process typically occurs in a closed chamber where compressed air is used to propel the beads at high velocities towards the surface of the material being treated. The impact of the beads gently removes unwanted contaminants, oxidization, or old coatings while leaving a smooth and clean surface.

How Does it Work?

The glass beads are available in various sizes, allowing for tailored applications depending on the material and the desired finish. The size and pressure of the glass beads can be adjusted based on the surface condition and the results expected. When the beads strike the surface, they create a peening effect rather than cutting into it, which means they do not damage the underlying material. This characteristic makes glass beads blasting especially useful for delicate components or finishes that require precision.

Applications

Glass beads blasting is versatile and finds applications across numerous sectors

1. Aerospace and Automotive Industries This method is often used to clean and prepare parts without altering their integrity. For aircraft and car components, where lightweight and durability are critical, the smooth finish achieved can enhance performance and aesthetics.

glass beads blasting

3. Medical Equipment The non-destructive nature of glass beads blasting makes it suitable for cleaning surgical instruments and devices that require a sterile finish.

4. Artistic Applications Artists and craftsmen use glass beads blasting for texturing surfaces, adding intricate designs to materials such as glass, stone, and ceramics.

Advantages of Glass Beads Blasting

- Non-Damaging Unlike harsher abrasives, glass beads provide a soft touch, preserving the integrity of the underlying material. - Environmentally Friendly Made from natural materials, glass beads are non-toxic and help reduce environmental impact. - Uniform Finish The use of rounded beads results in a consistent and high-quality finish across surfaces. - Versatility The adaptability of glass beads makes this method useful for various materials, including metals, glass, and plastics.

Considerations

While glass beads blasting offers numerous benefits, there are some considerations to keep in mind

- Moisture Sensitivity Glass beads can absorb moisture, which can affect the blasting efficiency. It is crucial to ensure the beads are dry before use. - Dust Generation As with any blasting process, fine dust can be generated, which may pose a safety hazard; therefore, adequate ventilation and personal protective equipment (PPE) are necessary. - Media Cost Although glass beads are reusable, the initial cost can be higher than other abrasive materials. It is important to consider the long-term benefits.

Conclusion

Glass beads blasting is a highly effective surface treatment process combining efficiency with gentle cleaning capabilities. Its widespread applications across industries underscore its importance and utility. As industries continually seek sustainable and effective cleaning solutions, glass beads blasting stands out as a reliable method that addresses both environmental concerns and operational needs. Whether for aerospace, automotive, construction, or artistic purposes, this technique provides a superior finishing option that supports the integrity and longevity of materials.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025