High-Quality Glass Microbeads for Various Applications

The Growing Importance of Glass Microbeads in Various Industries

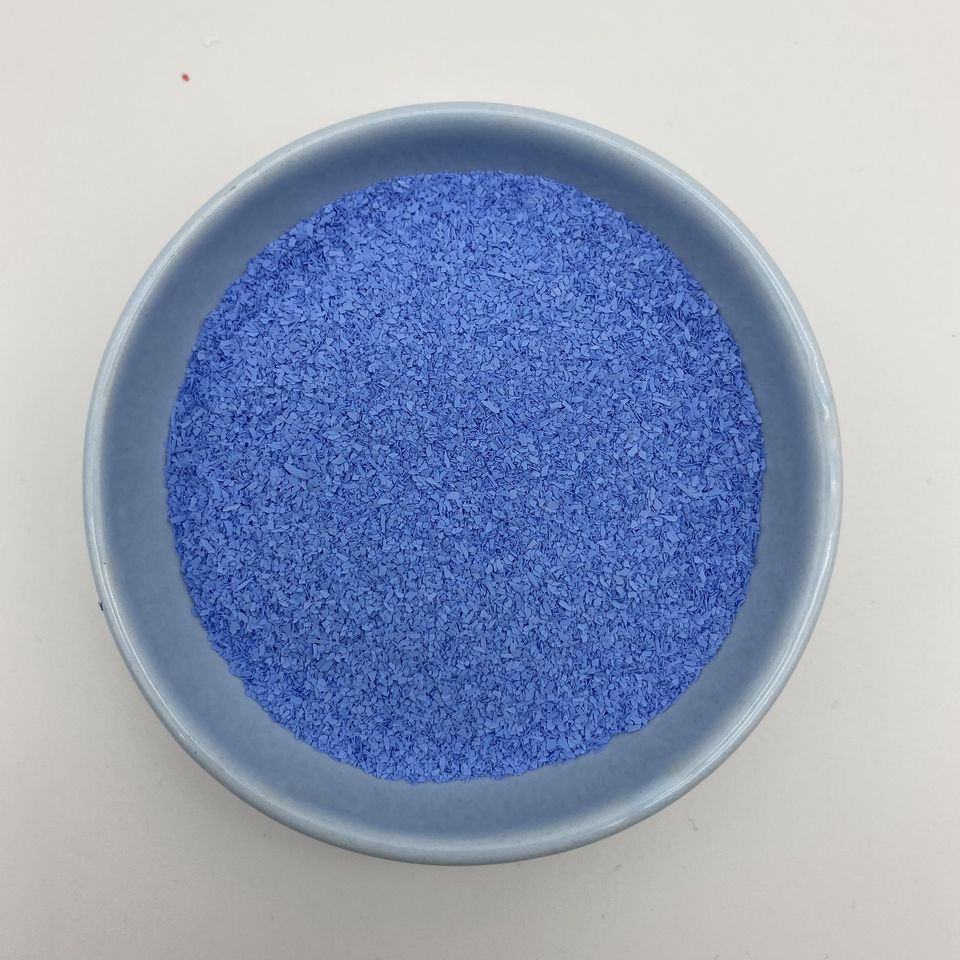

Glass microbeads, tiny spherical particles made from glass, have found their way into a multitude of applications across various industries due to their unique properties. These small glass spheres, typically ranging from 1 to 1000 micrometers in diameter, are characterized by their smooth surface, high sphericity, and extraordinary durability. Their increasing popularity is attributed to their versatility, eco-friendliness, and the various benefits they offer compared to traditional materials.

One of the primary applications of glass microbeads is in the cosmetics and personal care industry. They are often used as exfoliants in scrubs and facial cleansers, providing a gentle yet effective way to remove dead skin cells. Unlike plastic microbeads, which have faced severe environmental scrutiny and bans due to their contribution to ocean pollution, glass microbeads are biodegradable and can be safely integrated into the environment. This sustainability aspect makes them an appealing alternative for manufacturers aiming to create eco-friendly products.

In the realm of construction and manufacturing, glass microbeads are utilized for their reflective properties. When added to paints, coatings, and road markings, they enhance visibility, particularly in low-light conditions. This reflective quality is crucial for ensuring safety on roadways and in various construction settings. Furthermore, their lightweight nature and ability to improve the mechanical properties of composite materials make them valuable in the production of lightweight, strong components in automotive and aerospace industries.

glass microbeads

The medical field has also started to recognize the benefits of glass microbeads. They are used in diagnostics and therapeutic applications due to their biocompatibility and stability. For example, in drug delivery systems, glass microbeads can be engineered to release medication at targeted sites in the body, thereby improving the efficacy of treatments and minimizing side effects.

Moreover, the use of glass microbeads in the field of electronics is gaining traction. They can serve as fillers in various materials, enhancing electrical insulation and mechanical strength. Their non-conductive properties make them ideal for applications in circuit boards and various electronic components, contributing to the efficiency and longevity of devices.

Despite their numerous advantages, the production and disposal of glass microbeads need to be carefully managed to minimize environmental impact. As industries increasingly prioritize sustainability, the focus on responsible sourcing and end-of-life management is more critical than ever.

In conclusion, glass microbeads represent a forward-thinking solution across multiple sectors, from cosmetics to construction and medicine. Their eco-friendliness, versatility, and unique properties position them as a sustainable alternative to traditional materials, supporting the industry's shift towards greener practices. As research and development continue, the role of glass microbeads is set to expand, paving the way for innovations that respect both the environment and industrial needs.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025