2 月 . 07, 2025 05:21

Back to list

Concrete fly ash gray fly ash soil improvement add bulk fly ash for mixing plant

Fly ash, a byproduct of coal combustion in power plants, has emerged as a game-changer in the construction industry. Known for its pozzolanic properties, fly ash enhances the durability and strength of structures while also contributing to sustainable building practices. Its effective utilization in concrete and other building materials helps reduce the overall carbon footprint of the construction process, making it a preferred choice for environmentally conscious projects.

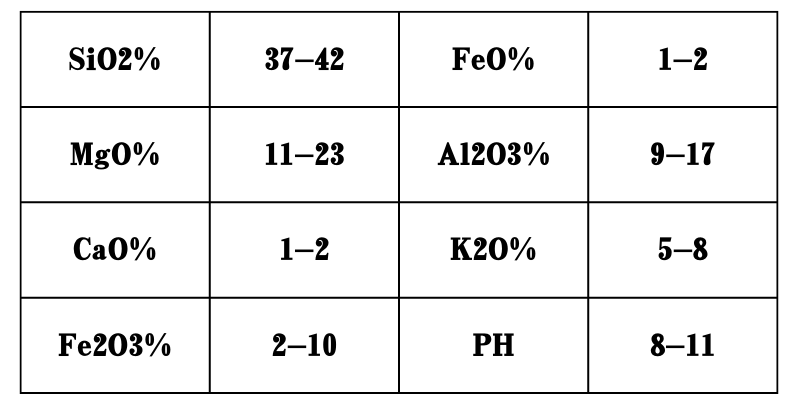

Despite its many advantages, the use of fly ash has a few challenges that need addressing. Variability in its chemical composition, depending on the coal source and combustion process, can affect its performance in concrete. Professionals in the construction and materials technology sectors are focusing on standardizing testing procedures and establishing guidelines to ensure consistency in fly ash quality across different markets. Ongoing research and collaborations between academics, industry leaders, and builders are essential to overcoming these hurdles and maximizing the potential of fly ash in construction. From a regulatory perspective, governments worldwide are recognizing the benefits of incorporating supplementary cementitious materials like fly ash into the built environment. Policies promoting the use of green materials in infrastructure projects are becoming more common, offering incentives to developers who prioritize sustainability. Consequently, the demand for fly ash is poised to grow, presenting a profitable opportunity for suppliers while simultaneously advancing global environmental objectives. A notable example of the successful application of fly ash in construction is the Hoover Dam Bypass project, where fly ash was extensively used in the concrete mixture. This project demonstrated not only the strength and durability of fly ash-infused concrete but also highlighted its role in large-scale infrastructure under demanding conditions. Similarly, iconic buildings and transit systems worldwide are increasingly leaning towards fly ash-based materials, showcasing its versatility and reliability. In sum, fly ash represents a pivotal resource in the quest for sustainable construction methods. Its role in enhancing concrete’s properties, reducing CO2 emissions, and promoting material efficiency makes it an invaluable ally in modern building practices. As industries and governments push for greener construction standards, fly ash stands out as a critical component with proven benefits and potential for further advancements. By focusing on quality control, regulatory support, and innovative applications, fly ash can significantly contribute to shaping a sustainable construction future.

Despite its many advantages, the use of fly ash has a few challenges that need addressing. Variability in its chemical composition, depending on the coal source and combustion process, can affect its performance in concrete. Professionals in the construction and materials technology sectors are focusing on standardizing testing procedures and establishing guidelines to ensure consistency in fly ash quality across different markets. Ongoing research and collaborations between academics, industry leaders, and builders are essential to overcoming these hurdles and maximizing the potential of fly ash in construction. From a regulatory perspective, governments worldwide are recognizing the benefits of incorporating supplementary cementitious materials like fly ash into the built environment. Policies promoting the use of green materials in infrastructure projects are becoming more common, offering incentives to developers who prioritize sustainability. Consequently, the demand for fly ash is poised to grow, presenting a profitable opportunity for suppliers while simultaneously advancing global environmental objectives. A notable example of the successful application of fly ash in construction is the Hoover Dam Bypass project, where fly ash was extensively used in the concrete mixture. This project demonstrated not only the strength and durability of fly ash-infused concrete but also highlighted its role in large-scale infrastructure under demanding conditions. Similarly, iconic buildings and transit systems worldwide are increasingly leaning towards fly ash-based materials, showcasing its versatility and reliability. In sum, fly ash represents a pivotal resource in the quest for sustainable construction methods. Its role in enhancing concrete’s properties, reducing CO2 emissions, and promoting material efficiency makes it an invaluable ally in modern building practices. As industries and governments push for greener construction standards, fly ash stands out as a critical component with proven benefits and potential for further advancements. By focusing on quality control, regulatory support, and innovative applications, fly ash can significantly contribute to shaping a sustainable construction future.

Share

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025