fly ash companies

The Rise of Fly Ash Companies Sustainable Solutions for the Concrete Industry

In recent years, the construction industry has faced increasing pressure to adopt more sustainable practices. One significant development in this sector is the growing utilization of fly ash, a byproduct of coal combustion, which has emerged as a valuable resource for many construction and concrete companies. This article explores the reasons behind the rise of fly ash companies and their impact on the industry.

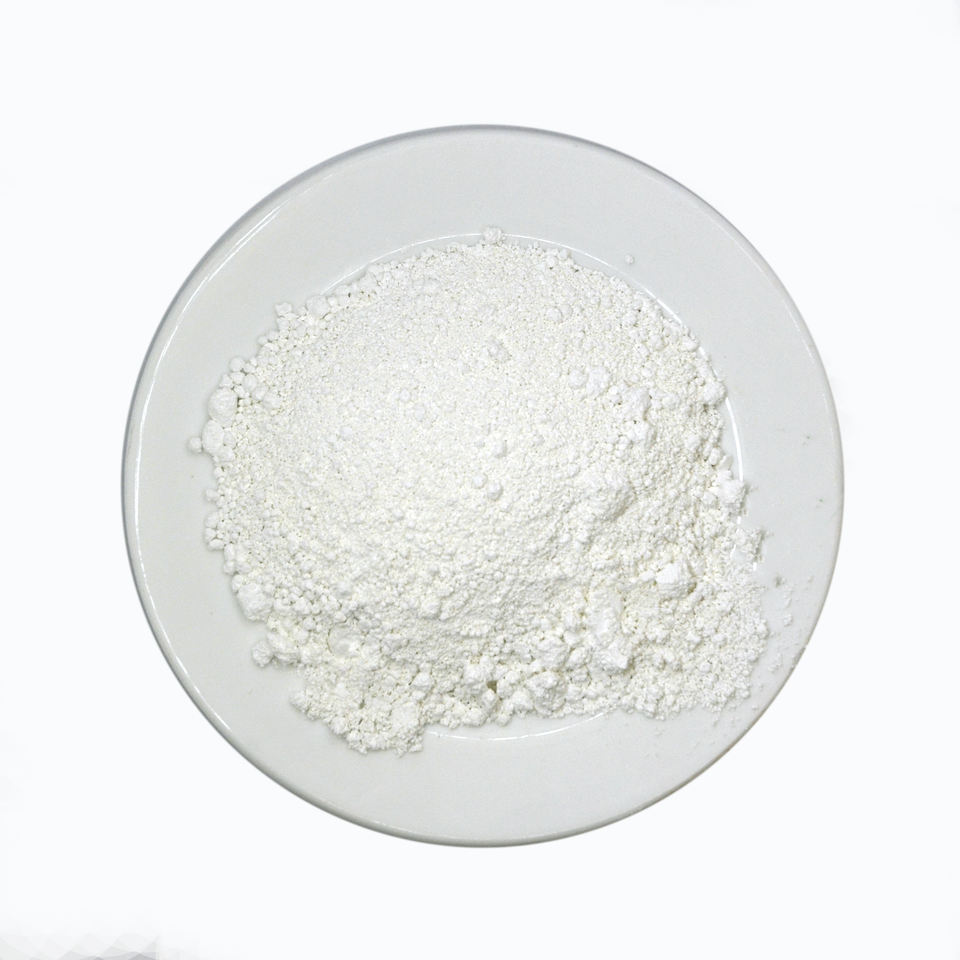

Understanding Fly Ash

Fly ash is produced when coal is burned in power plants. It is collected from the flue gases through electrostatic precipitators or bag filters. This fine, gray powder is rich in silica and alumina, making it a desirable additive in concrete production. When mixed with water and lime, fly ash reacts to form compounds that enhance the durability and strength of concrete.

Environmental Benefits

One of the primary drivers for the growth of fly ash companies is the environmental benefits associated with its use. Incorporating fly ash into concrete reduces the necessity for portland cement, which is energy-intensive to produce and contributes significantly to carbon dioxide emissions. By substituting a portion of cement with fly ash, concrete companies can lower their carbon footprint and promote a circular economy by recycling industrial waste.

Moreover, the utilization of fly ash helps mitigate the problem of landfill space. As the production of coal-fired power continues, the accumulation of fly ash can pose challenges for waste management. Fly ash companies provide a sustainable solution by transforming what would be waste into a valuable ingredient for construction, thus reducing the volume of material that needs to be landfilled.

Quality and Performance

fly ash companies

Fly ash has been shown to improve the workability, strength, and durability of concrete. Its spherical particles result in better flowability and reduce the water demand for concrete mixtures. Additionally, the pozzolanic properties of fly ash allow for enhanced resistance to sulfates and alkali-silica reactions, which can lead to cracking in concrete over time. As a result, many contractors and architects are increasingly specifying fly ash in their projects, further driving demand for fly ash companies.

Economic Advantages

The economic benefits of using fly ash are equally compelling. Fly ash is often more cost-effective than traditional portland cement, especially in regions where fly ash is locally available. This cost-effectiveness, combined with enhanced performance characteristics, makes it attractive to construction companies looking to stay competitive in the market. Furthermore, the integration of fly ash into concrete mixes can lead to longer-lasting structures, reducing maintenance and repair costs over the life cycle of a project.

Challenges Ahead

Despite the numerous advantages of fly ash, several challenges remain. The variability in fly ash quality, depending on the source of coal and combustion process, can affect its performance in concrete. Additionally, the decline in coal-fired power generation due to the shift toward renewable energy sources could lead to a shortage of fly ash in the future. Fly ash companies must innovate and adapt to these challenges by developing more refined quality control measures and exploring alternative sources of pozzolans.

Conclusion

The rise of fly ash companies represents a promising trend toward sustainable construction practices. With their potential to reduce environmental impact, enhance concrete performance, and provide economic advantages, these companies are paving the way for a greener future in the construction industry. As the demand for eco-friendly materials continues to grow, fly ash stands out as a remarkable example of how industrial byproducts can be transformed into high-value products, benefiting both the economy and the environment.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025