1 月 . 16, 2025 02:08

Back to list

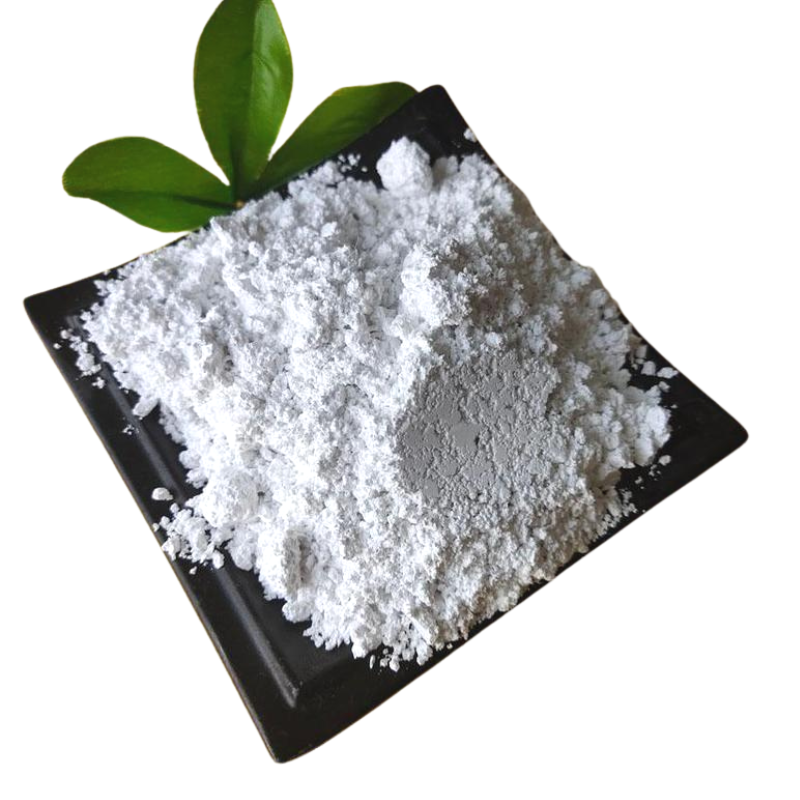

fly ash

Fly ash, a byproduct of coal combustion in power plants, has transformed from an industrial challenge to a pivotal material in sustainable construction. As awareness around sustainability in construction grows, architects, engineers, and construction firm proprietors are seeking out alternatives to reduce carbon footprints. Fly ash has emerged as a valuable ally in this mission.

For businesses looking to integrate fly ash into their products, the challenge lies not only in sourcing quality material but also in earning the confidence of stakeholders. This involves demonstrating compliance with standards such as ASTM C618 in the US or BS 3892 in the UK, which assure stakeholders of the fly ash's suitability for specific construction applications. Professional accreditations and certifications play a crucial role in establishing the material's credibility. However, as with all materials, careful consideration and quality control are paramount. Factors like the source of coal, combustion conditions, and collection methods can affect the physical and chemical properties of fly ash. Therefore, vigilant testing and screening procedures are essential to ensure consistent quality and performance when incorporating fly ash into construction projects. The economic implications of fly ash are equally promising. With its cost often lower than that of Portland cement, incorporating fly ash has the potential to reduce overall project costs. Additionally, its ability to improve the workability of concrete can reduce labor and time expenditures on-site. In conclusion, fly ash is not merely an industrial byproduct but a cornerstone of modern, sustainable construction practices. With an ever-growing database of successful applications worldwide and continuous advancements in technology and standards, fly ash presents a reliable, high-performance option for today's environmentally-savvy construction professionals. As we stride towards more sustainable building practices, the role of fly ash will undoubtedly become even more pronounced, helping to redefine the landscapes we inhabit with both economic and environmental benefits in mind.

For businesses looking to integrate fly ash into their products, the challenge lies not only in sourcing quality material but also in earning the confidence of stakeholders. This involves demonstrating compliance with standards such as ASTM C618 in the US or BS 3892 in the UK, which assure stakeholders of the fly ash's suitability for specific construction applications. Professional accreditations and certifications play a crucial role in establishing the material's credibility. However, as with all materials, careful consideration and quality control are paramount. Factors like the source of coal, combustion conditions, and collection methods can affect the physical and chemical properties of fly ash. Therefore, vigilant testing and screening procedures are essential to ensure consistent quality and performance when incorporating fly ash into construction projects. The economic implications of fly ash are equally promising. With its cost often lower than that of Portland cement, incorporating fly ash has the potential to reduce overall project costs. Additionally, its ability to improve the workability of concrete can reduce labor and time expenditures on-site. In conclusion, fly ash is not merely an industrial byproduct but a cornerstone of modern, sustainable construction practices. With an ever-growing database of successful applications worldwide and continuous advancements in technology and standards, fly ash presents a reliable, high-performance option for today's environmentally-savvy construction professionals. As we stride towards more sustainable building practices, the role of fly ash will undoubtedly become even more pronounced, helping to redefine the landscapes we inhabit with both economic and environmental benefits in mind.

Share

Next:

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025