Leading Suppliers of High-Quality Fluorite for Diverse Industrial Applications

Fluorite Manufacturers A Comprehensive Overview

Fluorite, also known as calcium fluoride (CaF2), is a naturally occurring mineral that has garnered significant attention for its diverse industrial applications. With an increasing demand for high-quality fluorite in various sectors, the role of fluorite manufacturers becomes crucial in meeting these needs. This article explores the significance of fluorite manufacturers, their processes, and the applications of fluorite that drive demand.

Fluorite is primarily mined for its utility in the production of aluminum, gasoline, gasoline additives, and other fluorinated chemicals. It is also a vital ingredient in the manufacturing of glass and ceramics, where it acts as a flux to lower melting temperatures and improve the quality of the final product. The growing emphasis on advanced materials and manufacturing processes has led to a surge in the need for purified and high-grade fluorite.

Fluorite manufacturers typically source their material from mines, where they extract and process fluorite ore. The processing involves crushing, grinding, and washing the ore to remove impurities and ensure the desired purity levels. The final product can vary in purity, with the highest grades often exceeding 97% CaF2. These premium grades are particularly sought after in industries such as metallurgy, ceramics, and chemical production, where quality standards are stringent.

fluorite manufacturer

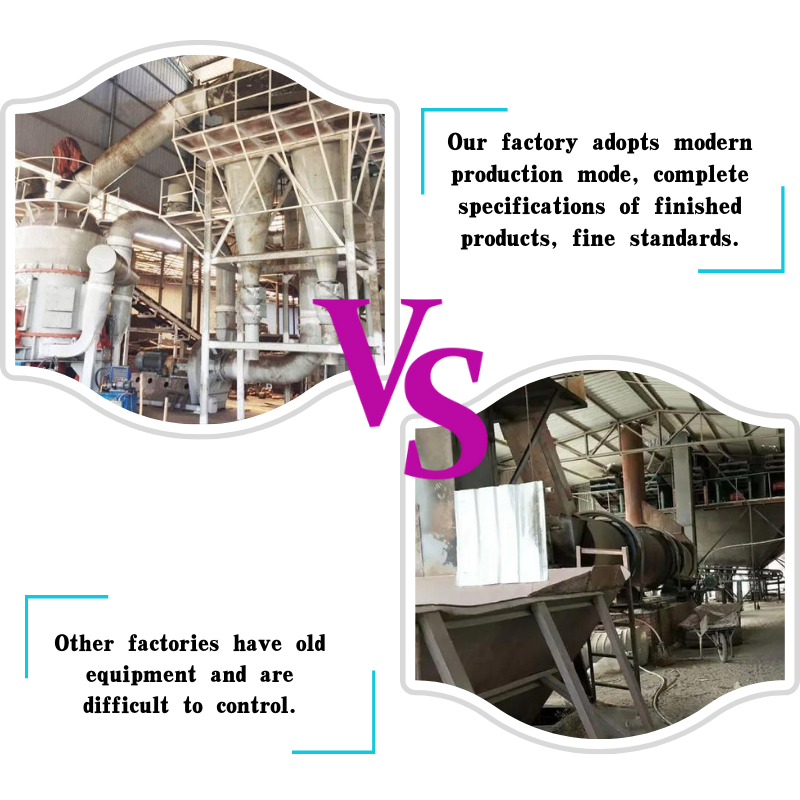

One of the key factors that differentiate fluorite manufacturers is their ability to maintain consistent quality and meet the demands of various industries. Leading manufacturers invest in state-of-the-art processing technologies and rigorous quality control measures to ensure their products meet international standards. This commitment to quality not only enhances their reputation but also fosters long-term relationships with clients in diverse sectors.

Furthermore, the increasing focus on sustainability and environmental regulations has prompted manufacturers to adopt more eco-friendly practices. Many manufacturers are exploring methods to minimize waste and improve resource efficiency throughout the production process. By implementing sustainable practices, they not only comply with regulations but also cater to the growing consumer preference for environmentally responsible products.

The global market for fluorite is witnessing significant growth, driven by rising demand from emerging economies and advancements in technology. As industries continue to innovate, the need for high-quality fluorite is expected to rise, providing opportunities for manufacturers to expand their operations and improve their product offerings.

In conclusion, fluorite manufacturers play an essential role in the supply chain of various industries by producing high-quality fluorite to meet specific applications. Their commitment to quality, sustainability, and innovation positions them favorably in a competitive market. As the demand for fluorite continues to grow, these manufacturers will remain at the forefront, driving progress and meeting the needs of a diverse range of clients. Whether in the realm of metallurgical applications, ceramics, or emerging technologies, fluorite manufacturers are vital players in ensuring that quality materials are readily available to foster industrial growth and innovation.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025