Exploring the Properties and Applications of Iron Oxide Black 330 in Various Industries

Understanding Iron Oxide Black 330 Properties, Uses, and Significance

Iron oxide black, specifically Iron Oxide Black 330, is a synthetic inorganic pigment widely used across various industries due to its unique properties and versatility. Recognized for its deep black hue, this pigment is produced through a series of chemical reactions involving iron salts and organic compounds, yielding a stable and non-toxic product suitable for numerous applications.

Composition and Properties

Iron oxide black belongs to the class of iron oxides, which are compounds formed by the combination of iron and oxygen. The chemical formula for iron oxide black is Fe3O4 or commonly expressed as Fe₂O₃•nH₂O in its hydrated form. Iron oxide black exhibits excellent opacity, tinting strength, and durability, making it an ideal choice for situations requiring strong, long-lasting color.

One of the most significant characteristics of Iron Oxide Black 330 is its exceptional lightfastness and resistance to fading when exposed to ultraviolet (UV) light. This makes it particularly valuable in applications where color longevity is critical, such as in coatings, plastics, and construction materials. Moreover, it is resistant to heat, chemicals, and solvents, ensuring that it maintains its integrity over time, even in harsh environments.

Applications

Iron Oxide Black 330 finds extensive use across various sectors. One of the primary industries utilizing this pigment is the coatings and paints industry. It is commonly used in architectural coatings, automotive paints, and protective coatings, providing a rich, deep black color while maintaining the required performance criteria for durability and safety.

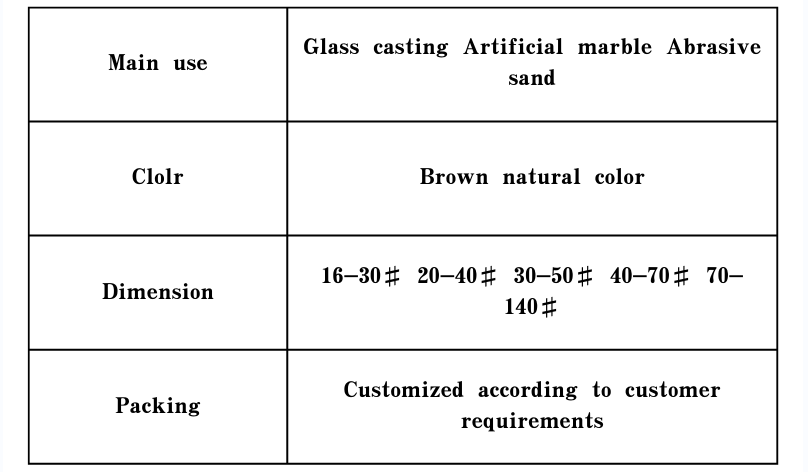

iron oxide black 330

In the construction sector, Iron Oxide Black is used in concrete and cement products, where it imparts a black finish to tiles, bricks, and other masonry. This is not only aesthetic but also functional, as darker colors can absorb heat and improve energy efficiency in certain applications. Additionally, its stability and non-toxicity make it a preferred choice for decorative landscaping stones and aggregates.

The plastics industry also benefits from Iron Oxide Black, which is used to enhance the color of plastic products. Its heat stability ensures that the pigmentation process does not compromise the physical properties of the plastic, making it an ideal option for a variety of consumer goods, from toys to automotive components.

Environmental and Safety Considerations

As a synthetic pigment, Iron Oxide Black 330 is considered environmentally friendly compared to many organic dyes and colorants, which may have harmful effects on human health and the ecosystem. Its low toxicity profile contributes to its safety for use in products like food packaging and children's toys, aligning with increasing consumer demands for safer, sustainable materials.

However, it is crucial to ensure that the production processes of Iron Oxide Black adhere to strict environmental regulations to minimize any impact caused during manufacturing. Sustainable practices and innovations in pigment production are essential to reducing the carbon footprint and ensuring compliance with safety standards.

Conclusion

In summary, Iron Oxide Black 330 is a versatile and robust pigment with profound significance across various industries. Its rich black color, durability, and environmental safety make it a popular choice for numerous applications, from paints and coatings to plastics and construction materials. As the demand for sustainable and non-toxic products continues to rise, Iron Oxide Black 330 stands out as an exemplary option, merging functionality with ecological responsibility. Understanding and leveraging the properties of this remarkable pigment can lead to innovative solutions and enhanced product offerings across multiple markets.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025