Exploring the Properties and Applications of 6% Tile Kaolin in Ceramic Industry

The Versatility of 6% Tile Kaolin

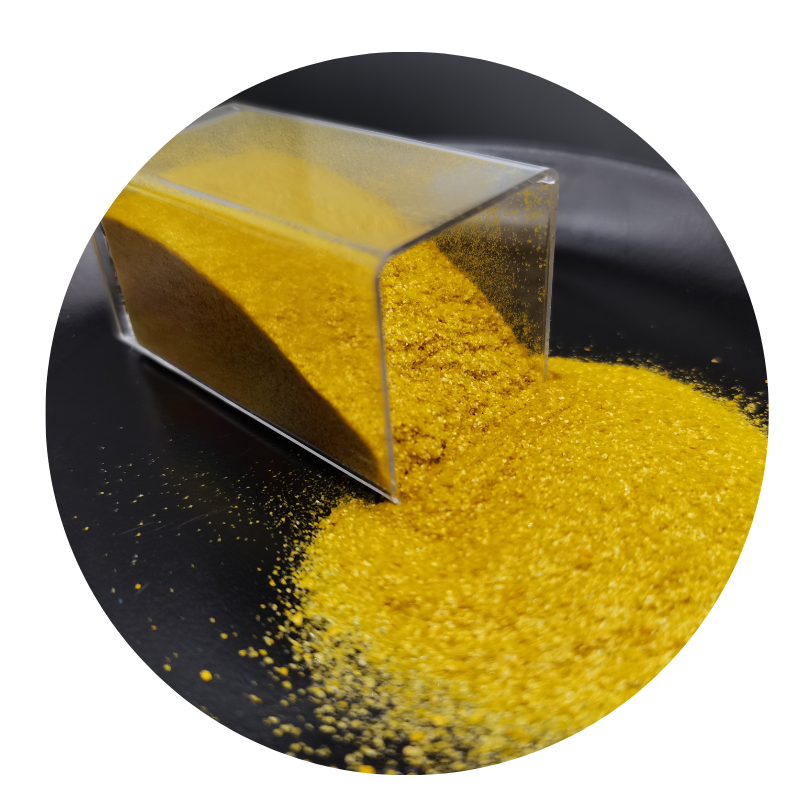

Kaolin, a naturally occurring clay mineral, is renowned for its unique properties and versatility in various applications. Among the various grades of kaolin, 6% tile kaolin stands out due to its specific composition and characteristics, making it particularly valuable in the ceramics industry, especially in tile production.

Kaolin is primarily composed of kaolinite, a layered silicate mineral that is known for its whiteness, fine particle size, and non-plastic behavior. The term 6% tile kaolin typically refers to a specific kaolin blend that contains around 6% impurities or additives designed to enhance the performance of tiles. The purity and quality of kaolin are crucial in determining the final product's characteristics, such as strength, color, and durability.

The Versatility of 6% Tile Kaolin

In addition to its mechanical benefits, 6% tile kaolin plays a significant role in the thermal properties of ceramic tiles. During firing, kaolin helps in achieving even heat distribution, reducing the risk of warping or cracking. This thermal stability is essential for ensuring that the tiles maintain their integrity over time, even under varying temperature conditions. Furthermore, the white coloration of kaolin allows for a brighter and more uniform glaze finish, enhancing the visual quality of the tiles.

6 tile kaolin

The compatibility of 6% tile kaolin with other raw materials used in tile production is another key feature that makes it a preferred choice among manufacturers. It can be easily blended with feldspar, quartz, and other additives to create customized formulations that meet specific performance standards. This adaptability allows manufacturers to produce a wide range of tile varieties, from traditional ceramic tiles to advanced porcelain options, catering to diverse market needs.

Environmental considerations are also increasingly influencing the choice of materials in the ceramics industry. Fortunately, kaolin is considered an eco-friendly option, as it is abundantly available and naturally sourced. Its low toxicity and minimal environmental impact during extraction and processing make it a sustainable choice for manufacturers who are striving to reduce their carbon footprint.

Moreover, the rise in demand for high-quality tiles in residential and commercial projects has driven innovation in kaolin applications. Research and development efforts are focused on improving the properties of 6% tile kaolin, such as its workability and firing behaviors, which can lead to the production of even more advanced ceramic materials.

In conclusion, 6% tile kaolin is a crucial component in the production of high-quality ceramic tiles, offering a blend of mechanical strength, aesthetic appeal, and environmental sustainability. Its unique properties make it an essential raw material in the ceramics industry, providing manufacturers with the ability to produce durable, attractive, and eco-friendly tiles that meet modern consumer demands. As the industry continues to evolve, the role of kaolin will likely expand, paving the way for innovative applications and enhanced product performance.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025