Exploring the Production Process and Benefits of Perlite and Vermiculite in Modern Agriculture

The Perlite and Vermiculite Factory A Cornerstone of Modern Horticulture and Construction

In recent years, the demand for lightweight and versatile materials in various industries has surged. Among these materials, perlite and vermiculite stand out as two highly sought after resources, primarily due to their exceptional properties and wide range of applications. The perlite and vermiculite factory plays a crucial role in producing these aggregates, which are invaluable to horticulture, construction, and environmental remediation.

Understanding Perlite and Vermiculite

Perlite is a volcanic glass that expands when heated to high temperatures. This process, known as expansion, transforms perlite into a lightweight, porous substance that is commonly used in potting mixes, soil conditioners, and hydroponic systems. Its ability to retain moisture while providing excellent aeration makes it an ideal choice for gardeners and commercial growers alike.

On the other hand, vermiculite is a mineral that undergoes a similar expansion process when heated. It is known for its excellent insulation properties and its capability to retain water and nutrients. Vermiculite is widely used in construction materials, such as insulation, as well as in horticulture for seed starting and growing plants in a controlled environment.

The Role of the Factory

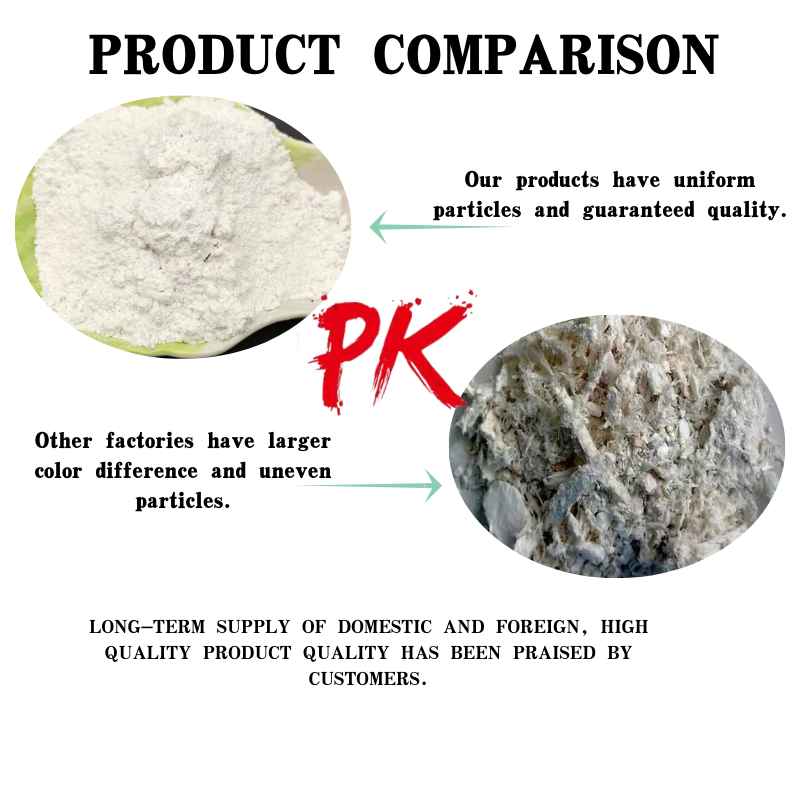

The perlite and vermiculite factory is integral in processing these materials to meet industrial standards and customer specifications. The factory employs advanced machinery to extract, crush, and expand perlite and vermiculite, ensuring consistent quality and performance. Quality control is paramount; the factory implements rigorous testing to ensure that the final products meet the requirements for various applications.

The production process begins with sourcing raw materials, typically from mining operations. After extracting perlite and vermiculite, the materials are crushed into smaller particles. For perlite, this is followed by heating in large furnaces which causes the material to expand and create the porous structure that is characteristic of perlite. For vermiculite, the process includes exfoliation, which also involves high-temperature heating to expand the flakes.

the perlite and vermiculite factory

Applications and Benefits

The applications of perlite and vermiculite are vast. In horticulture, they are mixed into potting soils to improve drainage and aeration, providing an optimal environment for root growth. Their lightweight nature allows for easy handling and transportation, making them popular materials for both amateur and professional gardeners.

In construction, perlite is often used as an aggregate in lightweight concrete, providing thermal insulation and fire resistance. Vermiculite, with its superior insulation properties, is commonly used in attic insulation, soundproofing, and as a lightweight fill material in various construction applications. The ability of both materials to absorb and retain moisture contributes to their usefulness in applications that require temperature regulation and moisture control.

Environmental Considerations

The perlite and vermiculite industry is also taking strides towards sustainability. Many factories are focusing on environmentally friendly practices, such as minimizing waste, optimizing energy usage, and ensuring that the extraction of raw materials is done responsibly. These efforts not only help in conserving natural resources but also contribute to a healthier environment.

Conclusion

The perlite and vermiculite factory is a critical player in delivering high-quality materials that are essential across multiple industries. From enhancing the growth of plants in gardens to providing insulation in modern buildings, perlite and vermiculite continue to demonstrate their versatility and importance. As industries evolve and the demand for sustainable materials grows, the significance of these factories will only increase, ensuring that they remain at the forefront of innovation in horticulture and construction.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025