Exploring the Best OEM Mica Factories for High-Quality Mineral Supply and Production Solutions

The Landscape of OEM Mica Factories

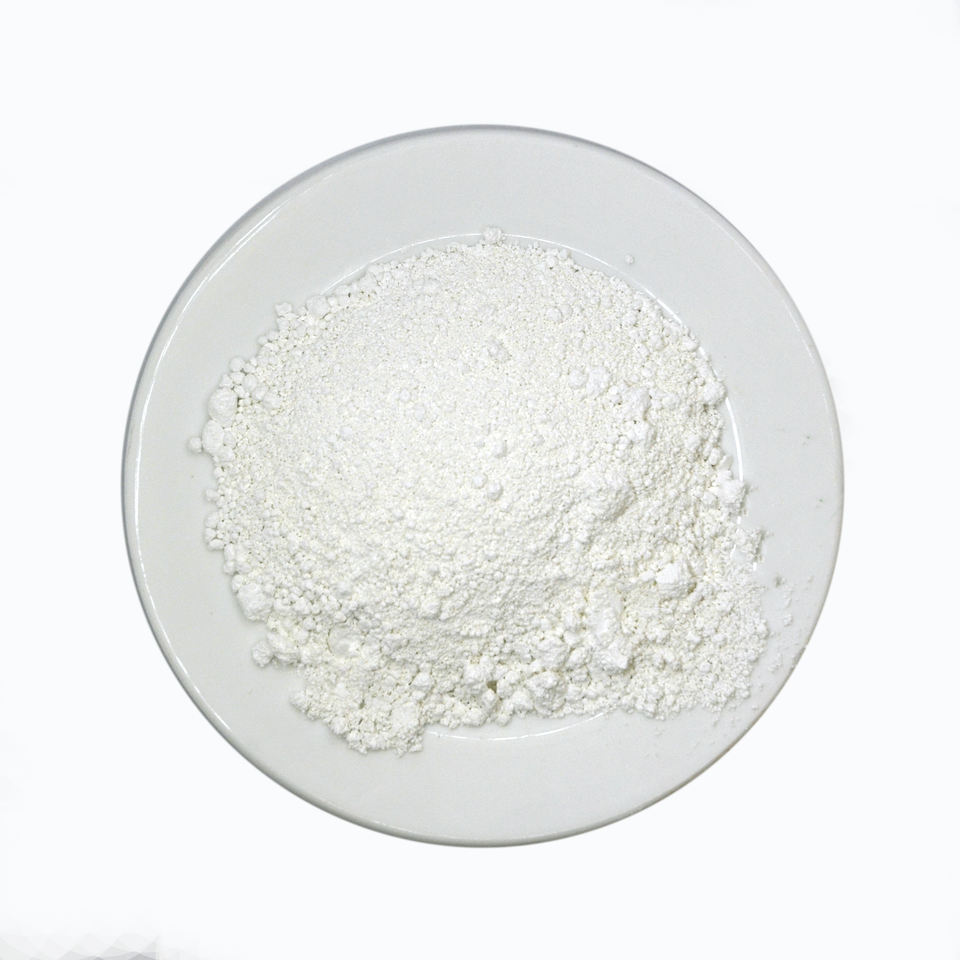

Mica, a naturally occurring mineral, is renowned for its unique properties, including flexibility, electrical insulation, and resistance to high temperatures. Given these characteristics, it finds extensive applications across various industries, particularly in cosmetics, electronics, and automotive sectors. With the growing demand for mica and the need for tailored solutions, Original Equipment Manufacturer (OEM) mica factories have emerged as significant players in the market.

OEM mica factories are specialized production facilities that manufacture mica products based on specific requirements set by other companies. These factories are equipped to produce various forms of mica, including mica flakes, powders, and sheets, fulfilling customized orders that meet the specifications of their clients. This business model is particularly advantageous for companies looking to incorporate mica into their products without investing heavily in manufacturing infrastructure.

The Landscape of OEM Mica Factories

Beyond cosmetics, the electrical and electronics sectors significantly benefit from OEM mica factories. Mica is crucial in the manufacturing of insulators, capacitors, and heat shields due to its excellent dielectric properties. OEM factories can tailor the thickness and size of the mica sheets or strips according to the precise requirements of electronic components, thus enhancing performance and contributing to device longevity. The collaboration between OEMs and mica manufacturers facilitates innovation and efficiency, as companies can quickly adapt to emerging technological trends.

oem mica factories

Moreover, the sustainability of mica sourcing has come under scrutiny, particularly in relation to mining practices. Many OEM mica factories are now adopting responsible sourcing practices that adhere to ethical standards. This includes ensuring that mica is obtained from conflict-free regions and promoting fair labor practices. By supporting manufacturers that prioritize sustainability, companies can enhance their brand reputation and appeal to environmentally conscious consumers.

The global landscape for OEM mica factories is ever-evolving. While Asia, particularly India, has been a traditional hub for mica production, the rise of automated and technologically advanced facilities in other regions, such as Europe and North America, is beginning to change the dynamics. These regions focus on advanced manufacturing techniques, including blending mica with other materials to create composite products. This innovation expands the potential applications of mica, making it even more versatile.

However, the OEM mica factory sector does face challenges. Fluctuations in raw material prices, regulatory changes, and the need for continuous innovation can impact operational efficiency and profitability. Companies must navigate these challenges while ensuring that they meet the growing expectations of clients for high-quality, customizable products.

In conclusion, OEM mica factories play a pivotal role in the modern manufacturing landscape. They provide essential materials that cater to diverse industries while promoting responsible sourcing and manufacturing practices. As global demand for mica continues to rise, these factories will need to adapt and innovate to remain competitive. Collaboration between OEMs and mica manufacturers represents a promising path forward, ensuring that high-quality mica products are consistently available to meet the needs of various sectors. The future of OEM mica factories looks bright, driven by advancements in technology and a commitment to sustainability and quality.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025