1 月 . 16, 2025 00:55

Back to list

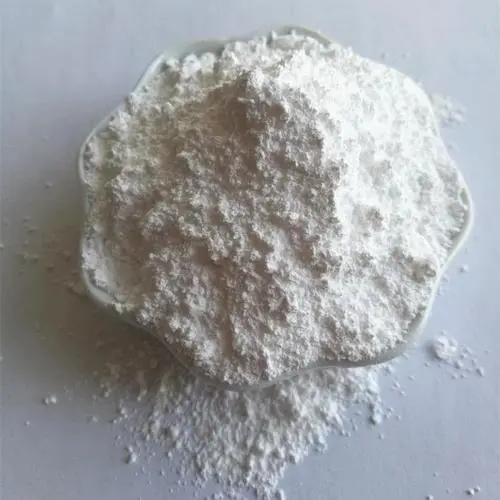

expansion perlite production

Expansion perlite production is a complex yet fascinating process that transforms raw perlite ore into a versatile and highly sought-after material across various industries. With decades of experience in the field, a deep understanding of industrial mineralogy, and a commitment to sustainable practices, our company stands at the forefront of this industry. Our expertise ensures that we deliver the highest quality expanded perlite for diverse applications while maintaining eco-friendly practices.

Authoritativeness and trustworthiness are of utmost importance in our operations. Over the years, we have built solid partnerships with leading construction firms, major horticultural suppliers, and industrial manufacturers. Our consistent delivery of high-quality expanded perlite has earned us certifications and endorsements from industry regulatory bodies and customer testimonials that speak volumes about our reliability and product efficacy. Furthermore, our team of seasoned professionals is dedicated to continuous improvement and innovation. We conduct regular research and development activities to enhance our production techniques, ensuring that our perlite meets the ever-evolving needs of our clients. Moreover, by investing in cutting-edge research, we aim to discover new applications, further establishing our authority in the field. Trust is solidified by transparency and adherence to ethical standards. We are open about our production processes and proactively engage with local communities and stakeholders to ensure they benefit from our operations. Our commitment to reducing our carbon footprint is unwavering; we employ energy-efficient technologies and pursue waste minimization strategies across our facilities. Ultimately, expansion perlite production is not just a manufacturing process—it is a blend of science, environmental stewardship, and industrial expertise. Choosing our product means relying on a trusted partner who is committed to delivering excellence while preserving our planet for future generations.

Authoritativeness and trustworthiness are of utmost importance in our operations. Over the years, we have built solid partnerships with leading construction firms, major horticultural suppliers, and industrial manufacturers. Our consistent delivery of high-quality expanded perlite has earned us certifications and endorsements from industry regulatory bodies and customer testimonials that speak volumes about our reliability and product efficacy. Furthermore, our team of seasoned professionals is dedicated to continuous improvement and innovation. We conduct regular research and development activities to enhance our production techniques, ensuring that our perlite meets the ever-evolving needs of our clients. Moreover, by investing in cutting-edge research, we aim to discover new applications, further establishing our authority in the field. Trust is solidified by transparency and adherence to ethical standards. We are open about our production processes and proactively engage with local communities and stakeholders to ensure they benefit from our operations. Our commitment to reducing our carbon footprint is unwavering; we employ energy-efficient technologies and pursue waste minimization strategies across our facilities. Ultimately, expansion perlite production is not just a manufacturing process—it is a blend of science, environmental stewardship, and industrial expertise. Choosing our product means relying on a trusted partner who is committed to delivering excellence while preserving our planet for future generations.

Share

Next:

Latest news

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025