custom pearl mica powder factories

Custom Pearl Mica Powder Factories Crafting Unique Aesthetics for a Brighter Tomorrow

In recent years, the popularity of pearl mica powder has skyrocketed, thanks to its versatility and the enchanting visual effects it provides across various industries. From cosmetics to food and crafts, custom pearl mica powder has become an essential ingredient for countless products. With the rising demand, there has been a notable increase in custom pearl mica powder factories that cater to the specific needs and preferences of consumers. This article explores the significance of these factories, the process of producing custom mica powder, and the numerous applications that make this product a staple in several markets.

Understanding Mica Powder and Its Charm

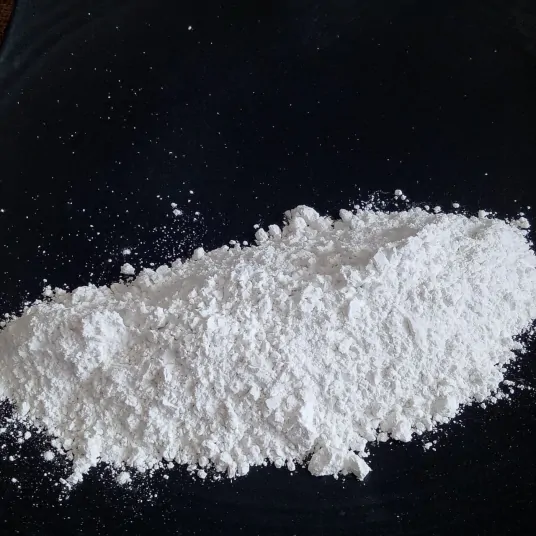

Mica powder is derived from a group of silicate minerals known for their unique shimmering characteristics. When ground into a fine powder, mica produces a stunning visual effect, reminiscent of pearls, which is why it is often referred to as pearl mica powder. The natural light-reflecting properties of mica impart a luxurious finish to any product it complements, making it particularly popular in the cosmetic industry for use in makeup, highlighters, and nail polishes. Furthermore, its non-toxic and hypoallergenic nature has made it a favored choice for products aimed at sensitive skin.

The Rise of Customization

In an era where personalized products are highly sought after, custom pearl mica powder factories emerge as a solution to meet diverse consumer needs. These factories offer tailoring options that allow brands to create unique shades, textures, and formulations. Customers can choose specific pigments, particle sizes, and even blended options, ensuring that the final product aligns perfectly with their brand identity.

Customization also extends to sustainability practices. Many forward-thinking factories emphasize eco-friendly manufacturing processes, sourcing mica from ethically responsible suppliers, and employing green technologies to minimize their environmental footprint. This shift not only enhances product appeal but also resonates with the increasing number of consumers who prioritize sustainability in their purchasing decisions.

Manufacturing Process of Custom Pearl Mica Powder

The production of custom pearl mica powder generally follows a meticulous process that involves several stages

1. Sourcing Raw Materials The foundation of quality mica powder begins with sourcing high-grade mica from reliable suppliers. This raw material is often mined from naturally occurring deposits, ensuring top-notch quality.

custom pearl mica powder factories

2. Processing Once the mica is obtained, it undergoes a grinding process to achieve the desired texture and fineness. This step is crucial as the right particle size greatly influences the sheen and application of the mica powder.

3. Coloring and Blending To achieve custom colors, manufacturers mix various pigments with the ground mica powder. This blending phase can produce an infinite range of hues, allowing clients to choose colors that fit their branding.

4. Quality Control Each batch is rigorously tested for consistency, quality, and safety to ensure it meets industry standards. This quality assurance is essential, especially for cosmetic applications.

5. Packaging and Distribution Finally, the custom pearl mica powder is packaged appropriately, ensuring it reaches clients in excellent condition, ready for use in their products.

Applications of Custom Pearl Mica Powder

The versatility of custom pearl mica powder means its applications span multiple sectors

- Cosmetics From shimmering eyeshadows to luxe lip products, mica powder enhances beauty items with sparkle and depth. - Crafting and DIY Projects Crafters use pearl mica powder to add vibrant colors and iridescent effects to soaps, candles, and arts and crafts projects. - Food Industry Edible mica powder is gaining traction for use in gourmet confectioneries, providing a stunning finish to cakes, chocolates, and beverages. - Industrial Applications Mica powder is also utilized in paints, coatings, and plastics, adding both aesthetic appeal and functional properties.

Conclusion

The emergence of custom pearl mica powder factories symbolizes a shift in consumer preferences towards personalization and quality. By combining innovative manufacturing techniques with ethical sourcing and a diverse range of applications, these factories are paving the way for a colorful future across multiple industries. As demand continues to rise, the potential for further creativity and sustainability within the realm of custom pearl mica powder is unlimited, promising exciting developments in product design and consumer choice.

Share

-

Premium Pigment Supplier Custom Solutions & Bulk OrdersNewsMay.30,2025

-

Top China Slag Fly Ash Manufacturer OEM Factory SolutionsNewsMay.30,2025

-

Natural Lava Rock & Pumice for Landscaping Durable Volcanic SolutionsNewsMay.30,2025

-

Custom Micro Silica Fume Powder Manufacturers High-Purity SolutionsNewsMay.29,2025

-

Custom Mica Powder Pigment Manufacturers Vibrant Colors & Bulk OrdersNewsMay.29,2025

-

Custom Micro Silica Fume Powder Manufacturers Premium QualityNewsMay.29,2025